A Stress Correction Method for Main Girder of Long-span Prestressed Concrete Cantilever Construction Bridge

A concrete and prestressing technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of not accurately reflecting the real stress state of the structure, not considering the elastic modulus of concrete, unfavorable bridge construction control, etc., to achieve Large practical engineering application value, ensure accuracy, improve the effect of solution accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

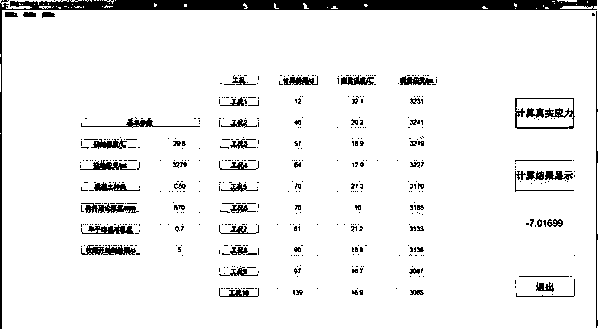

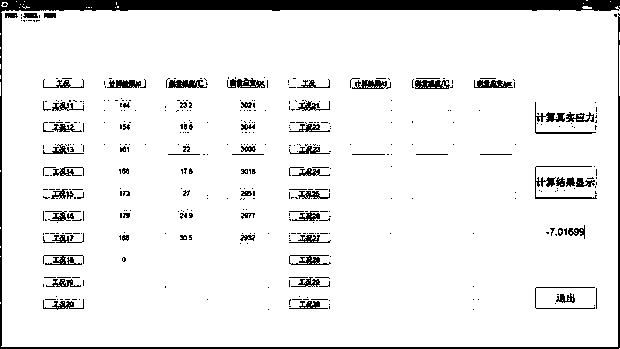

[0053] Such as Figure 1-6 , a stress correction method for the main girder of long-span prestressed concrete cantilever construction bridges, which considers the creep strain calculation method of the segmental construction characteristics of long-span bridges, and introduces the time-varying elastic modulus and the difference between certain two temporary periods The equivalent elastic modulus can more accurately eliminate the stress-free strain caused by creep, and select the corresponding secondary development technology to carry out secondary development of MATLAB, realizing the parameterized interface operation;

[0054] It specifically includes the following steps:

[0055] Step1: Calculation of strain value caused by concrete creep;

[0056] Step2: Calculation of the influence of time-varying elastic modulus on strain correction;

[0057] Step3: Calculation of strain value caused by temperature difference;

[0058] Step4: Calculation of strain value caused by concre...

Embodiment 2

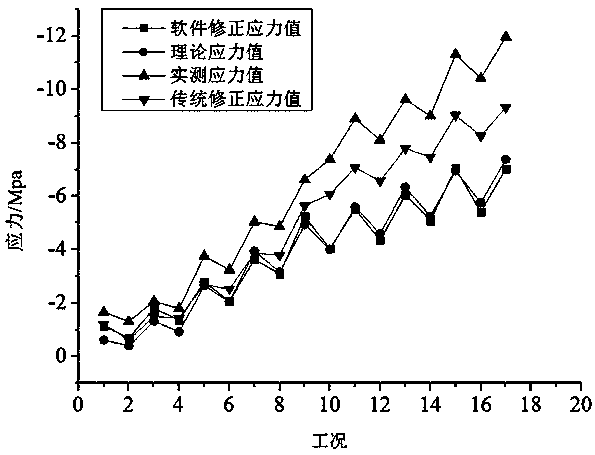

[0087] Such as Figure 1-6, the revised method was successfully used in the construction control of Shuangyang Bridge on Nanlong Railway. Nanlong Railway Shuangyang Bridge is located in Shuangyang Town, Zhangping City, Fujian Province, where the annual average relative humidity is 70%. Shuangyang Bridge spans Shuangyang River and Provincial Highway 208. It is a three-span prestressed concrete double-line continuous girder bridge with a span layout of 40.6m+64m+40.6m. The whole bridge is divided into two T-structures, which are symmetrically constructed using the hanging basket cantilever pouring method. The main girder is poured with C50 concrete. For the cast-in-place section, the closed section of the side span is 2.0m, and the closed section of the middle span is 2.0m. The superstructure is a single-box single-chamber oblique web variable-height variable-section box girder. A total of 11 stress measurement sections are arranged for the whole bridge, which are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com