Method considering influence of multiple factors for predicting fatigue life of large span power transmission wire

A fatigue life prediction, power transmission wire technology, applied in the application of stable tension/pressure testing material strength, electrical digital data processing, using repetitive force/pulse force testing material strength and other directions, can solve the problem of large errors and unfavorable overhead power transmission. Wire anti-vibration design, not considering the influence of the average stress of the wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

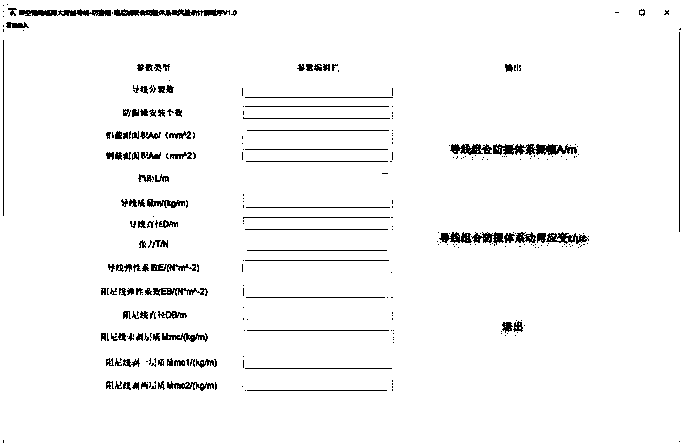

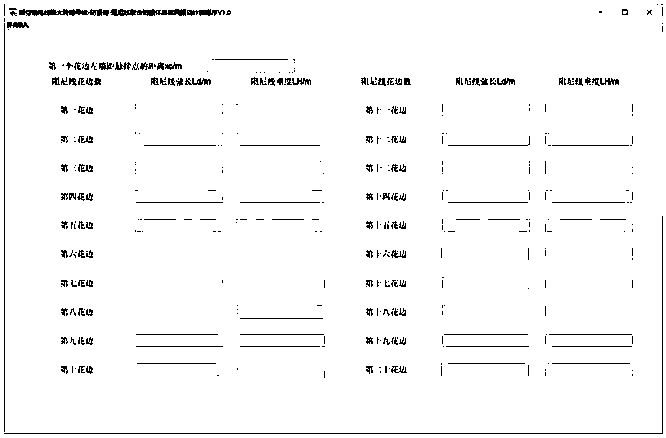

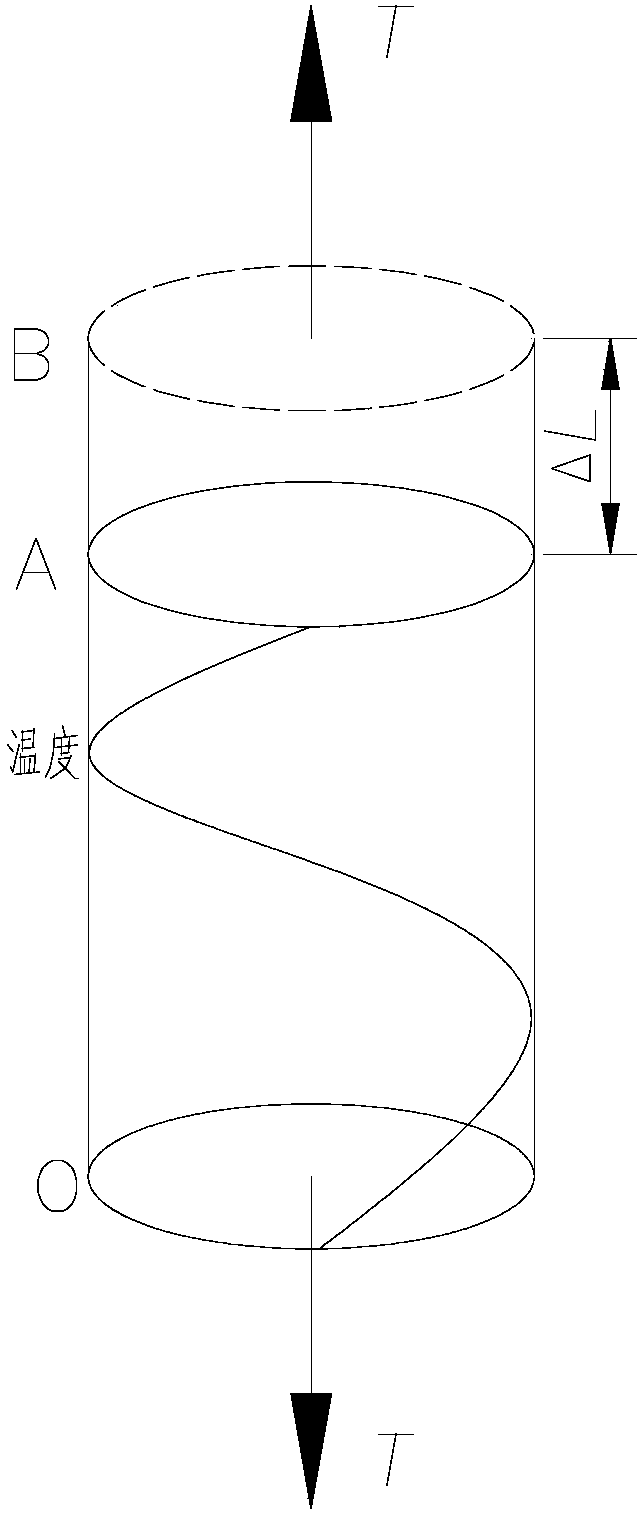

[0097] Aiming at the problem to be solved, the temperature of the conductor is calculated first, and then the mechanical balance equation of the conductor is established by using the deformation coordination conditions between the strands of the conductor to solve the average stress of each strand of the conductor under the action of tension and temperature. Then select the corresponding secondary development technology to carry out secondary development of MTALAB, use the MTALAB GUI interface to realize parameterized operation, and calculate the amplitude and dynamic stress of the wire conveniently and quickly. Then the Goodman stress correction model is used to calculate the equivalent alternating stress of the transmission wire, and then the Wholer safety curve is used to calculate the vibration resistance number N of the transmission wire. Consid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com