Arch bridge suspender tension optimization method for rectifying deviation in construction process

An optimization method and boom technology, applied in design optimization/simulation, bridge, bridge construction, etc., can solve problems such as poor matrix solution accuracy, cumbersome calculation of formal installation iterative method, and non-closed structural internal force, and achieve the optimization method and calculation process. Simple, great practical engineering application value, solve the effect of short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

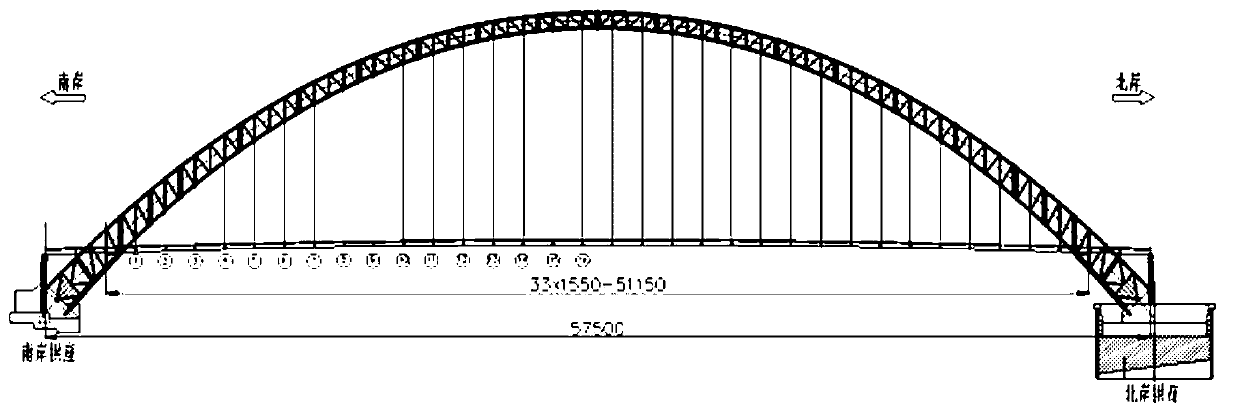

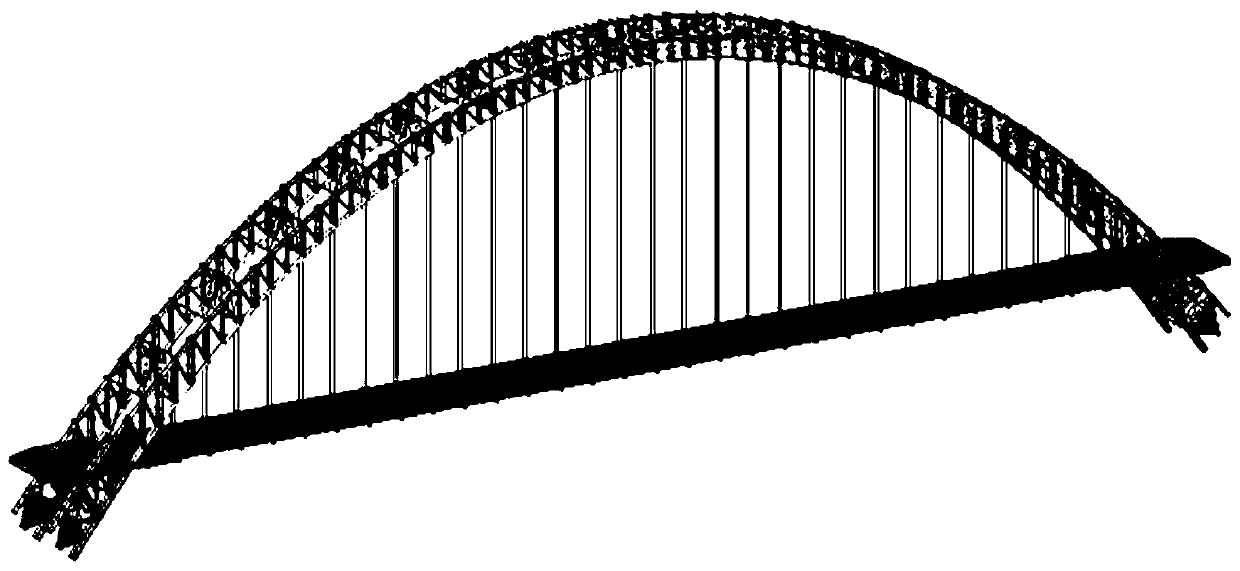

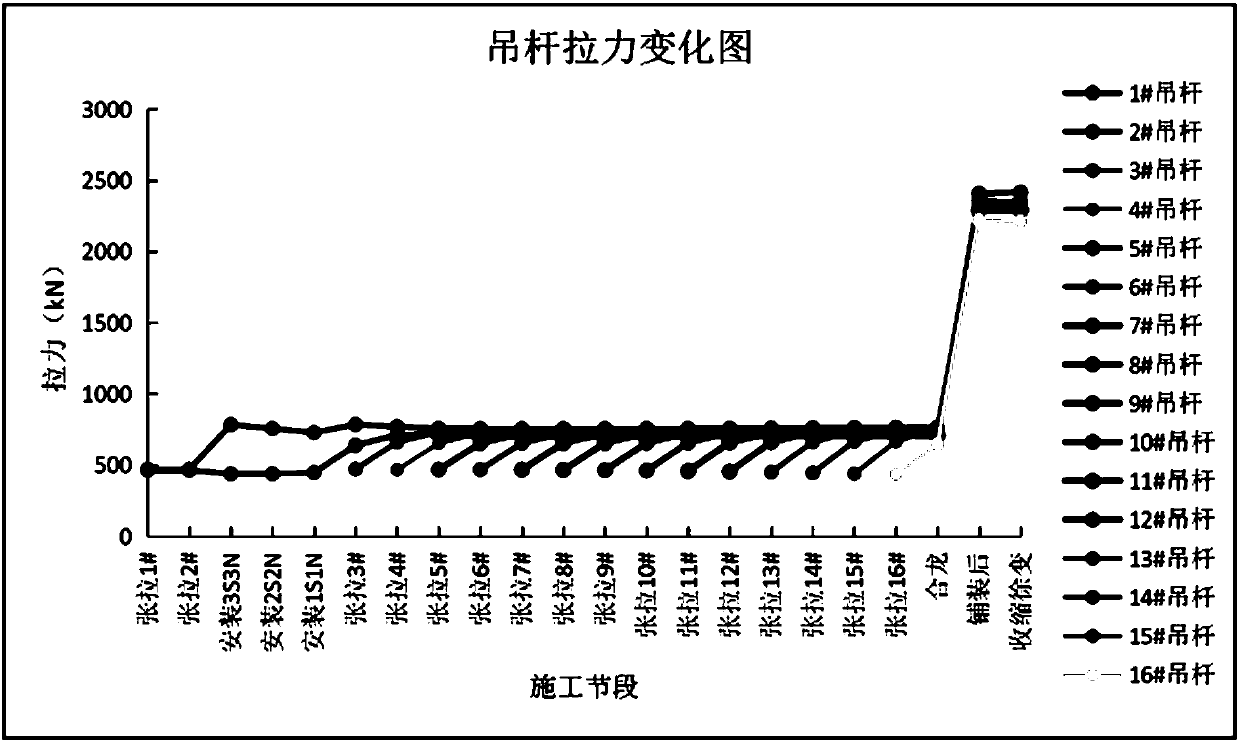

[0043] A middle-supported arch bridge, such as attached figure 1 As shown, due to the hoisting of the bridge deck after the concrete filled steel tube is poured, the pre-lifting amount of the hoisted lattice girder and the initial value of the tension of the boom are unknown. The breaking force of the boom in this project is 10094kN. The calculation model is as follows figure 2 As shown, calculate the span L=575000mm, delta1=5mm, delta2=150kN, dest=0mm, m=0,

[0044] X0=[470,470,470,470,470,470,470,470,470,470,470,470,470,470,470,470] T ;

[0045] dis0=[-58, -85, -101, -120, -144, -174, -208, -247, -291, -340, -391, -444, -498, -551, -599, -632 ] T ;

[0046] dis01=[-20,-17,-13,-5,5,15,26,37,47,55,58,53,37,8,-38,-101] T ;

[0047]

[0048] A 01 is A 0 The lower triangular matrix of the matrix is not listed in this paper; m=0 (that is, no correction is made). Bring parameters into the formula:

[0049] Constraint function:

[0050] Optimization equation:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com