Method for measuring tip clearance of turbine concave cavity blades

A technology of blade tip clearance and measurement method, which is applied in the field of tip clearance measurement of turbine cavity blades and tip clearance measurement of turbine cavity blades, can solve problems such as difficulty in meeting the needs of engine development, and achieve great practical engineering application value. Good economic benefits and the effect of shortening the R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

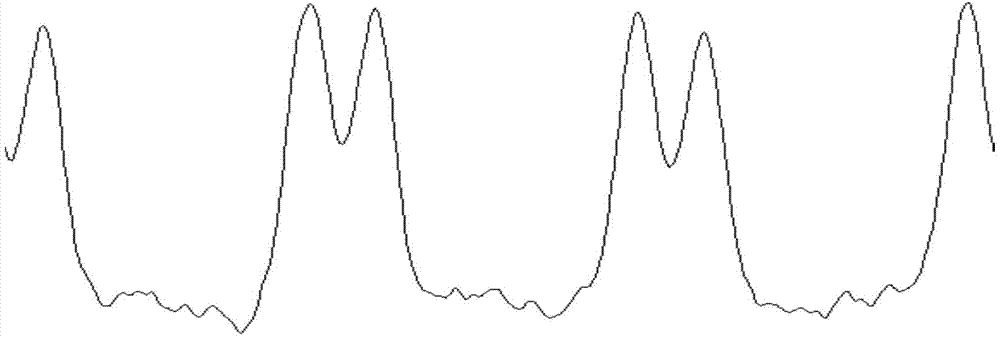

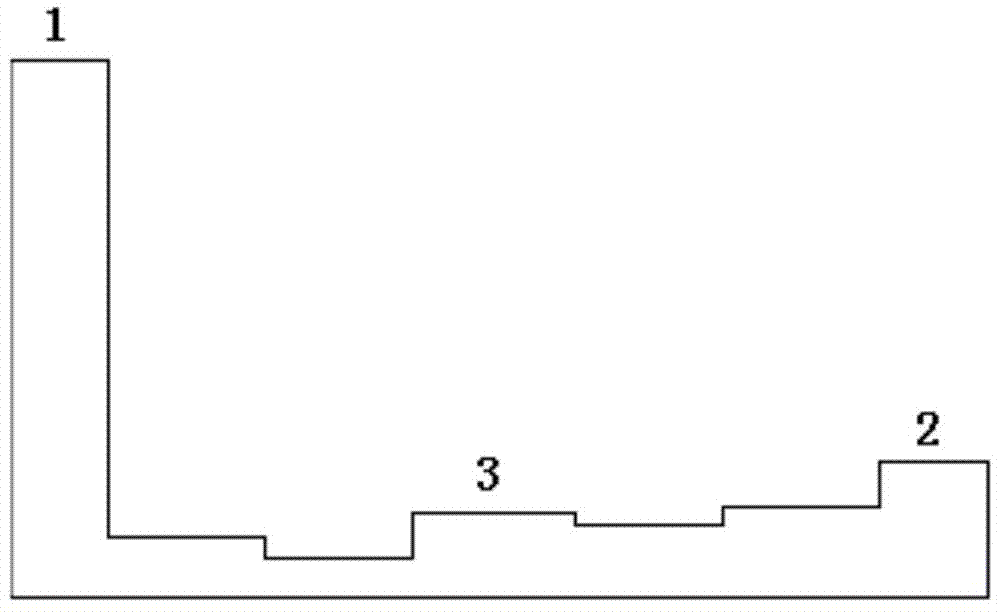

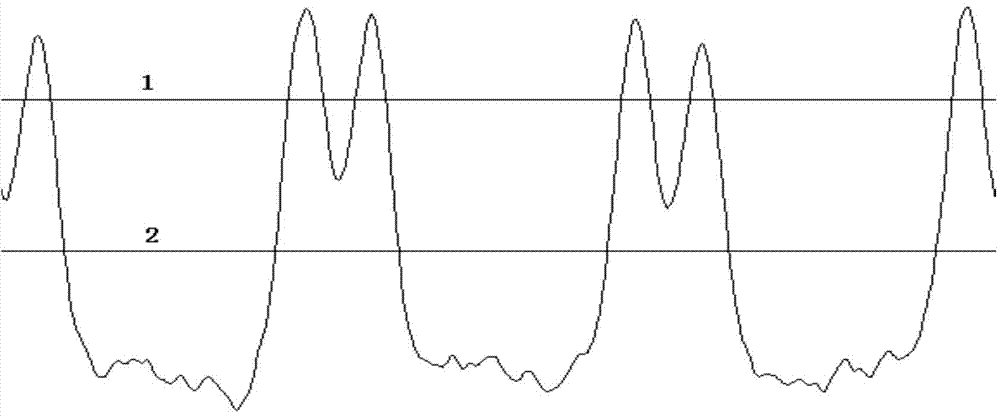

[0030] The measurement method provided by the invention includes signal acquisition, blade tip signal extraction and blade tip clearance calculation.

[0031] 1. Signal collection:

[0032] For the measurement of the rotating machinery signal, it is most beneficial to the signal analysis to adopt the whole cycle sampling. For tip clearance measurement, using an external synchronous trigger signal and sampling with the whole cycle sampling method can ensure that in any week of sampling data, the positional relationship between any sampling point and the blade is determined, as long as the total sampling time of a week is known The signal of each blade can be easily separated by the number of blades and the number of blades, and the calculation amount is small. The difficulty of sampling the whole cycle is how to obtain a sampling clock with a relatively high frequency. For g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com