Hidden anchor recess and manufacturing installation technology

An anchor hole and concealed technology, which is applied in the field of concealed anchor holes and manufacturing and installation technology, can solve problems such as unbalanced gaps, long installation cycles, and large on-site cutting volumes, so as to avoid secondary cutting volumes, improve construction conditions, The effect of reducing shipbuilding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

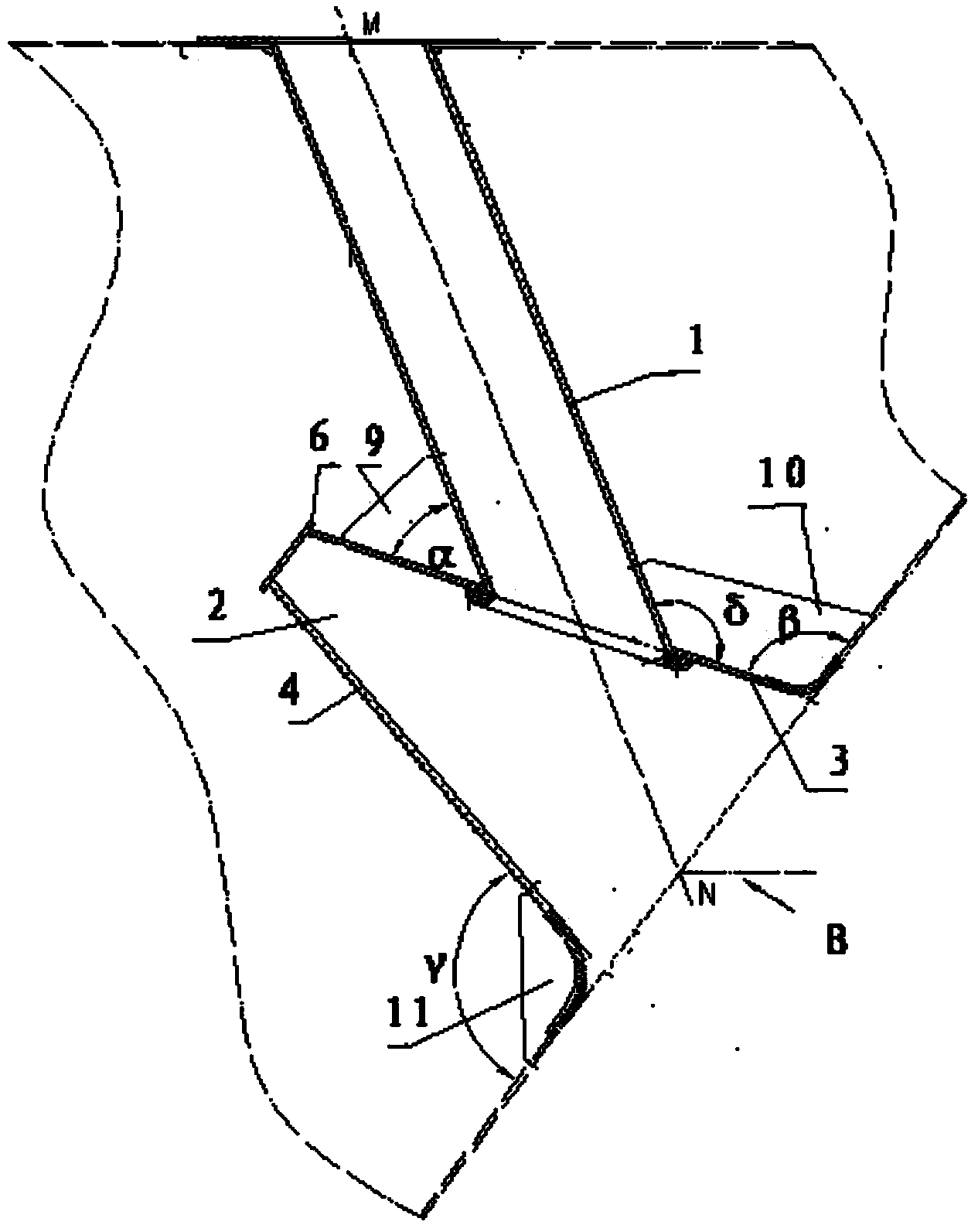

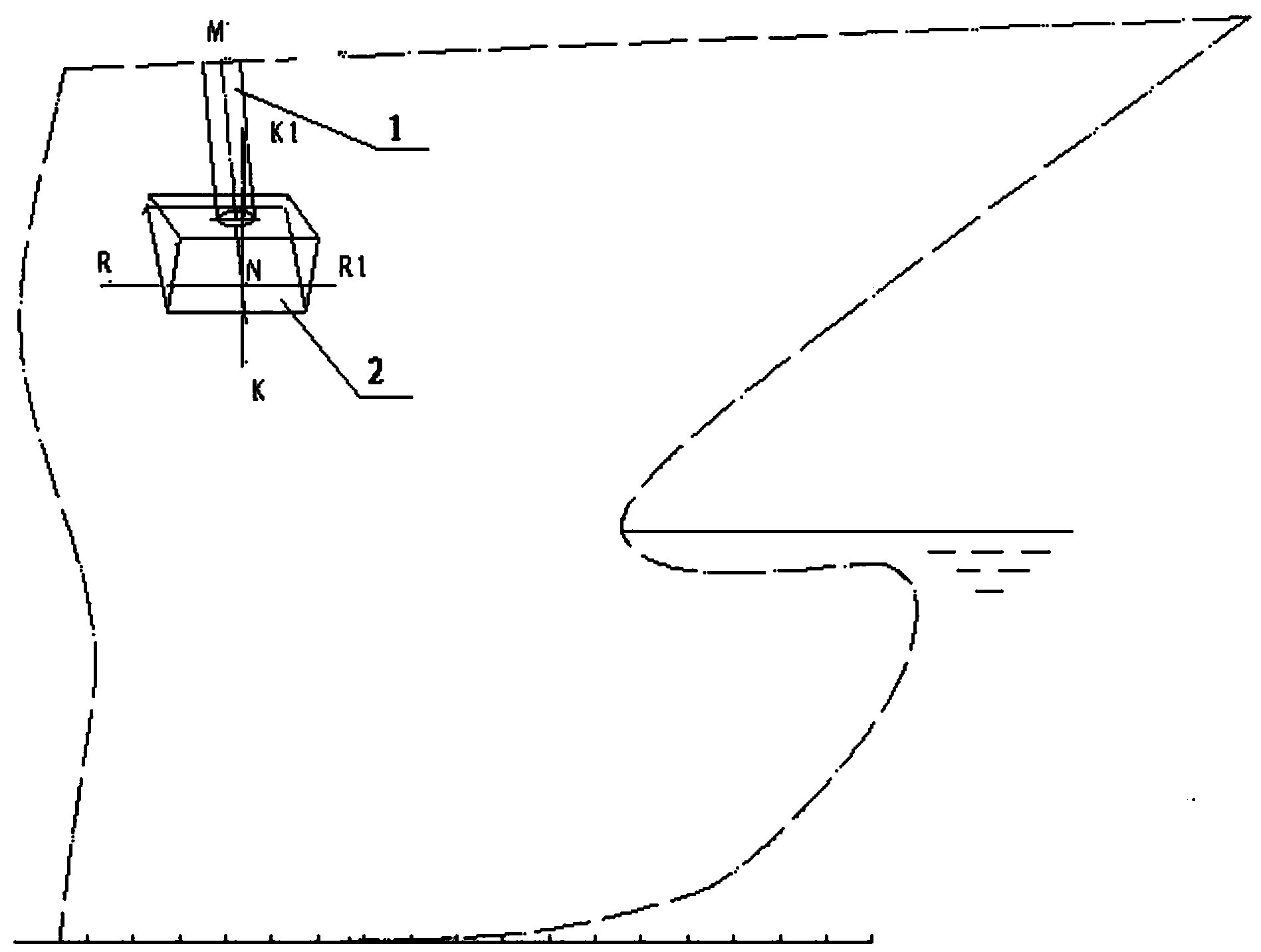

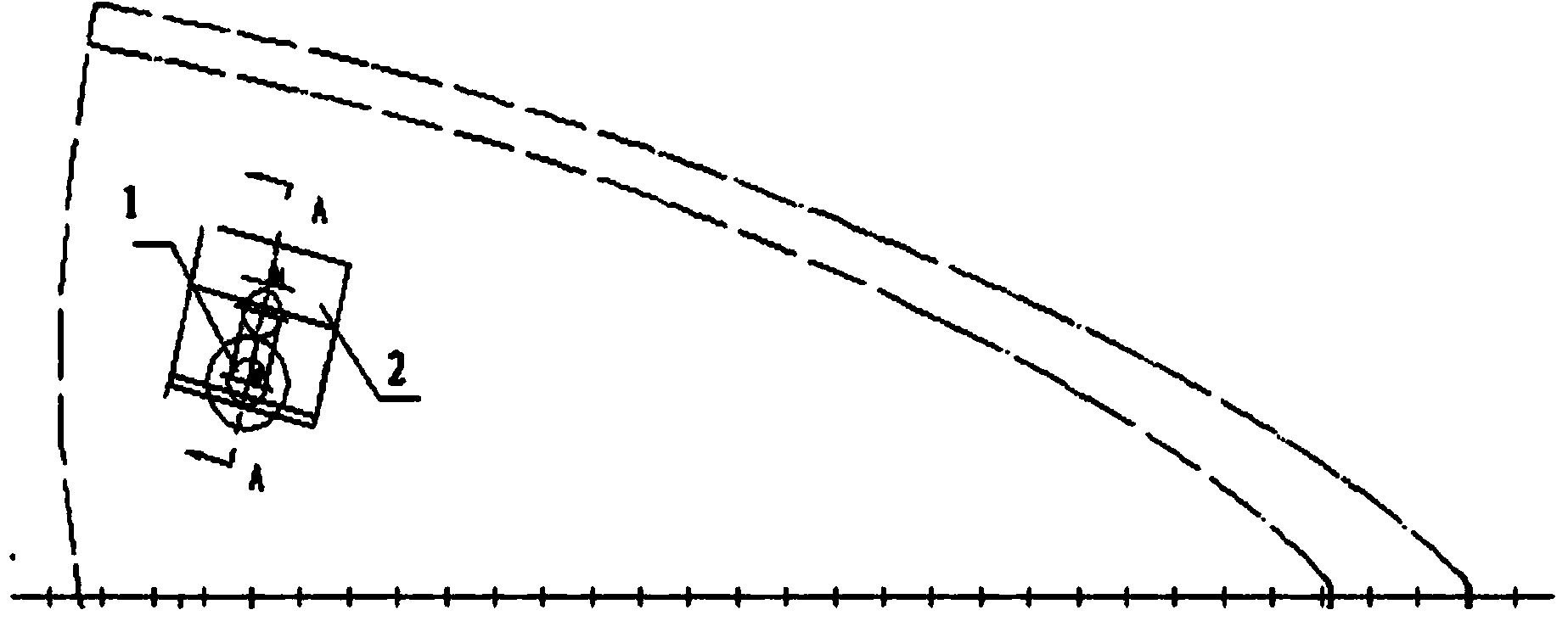

[0015] In the manufacture of a cruise ship, such as figure 1 , figure 2 As shown, the concealed anchor hole 2 is selected, which is located under the anchor chain cylinder 1, as shown in image 3 and Figure 4 As shown, the concealed anchor hole 2 is surrounded by an anchor hole end plate 6, an anchor hole side plate 5, an anchor hole bottom plate 4 and an anchor hole top plate 3 to form a box structure, and also includes a first bracket 7, a second bracket 8, The third bracket 9, the fourth bracket 10, the fifth bracket 11, the first bracket 7, and the second bracket 8 are located on the water plane R-R1 passing through the intersection point N of the centerline of the chain barrel 1 and the outer plate on, such as Figure 4 As shown, the sides of the first bracket 7 and the second bracket 8 are sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com