Dryer

A drying device and drying technology, applied in the directions of drying gas arrangement, drying, and preservation of seeds by drying, etc., can solve the problems of shortening drying time, drying with unrecorded absolute humidity of exhaust air, etc., and achieve the effect of reducing moisture gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, the case where this Embodiment is used for a grain dryer is demonstrated.

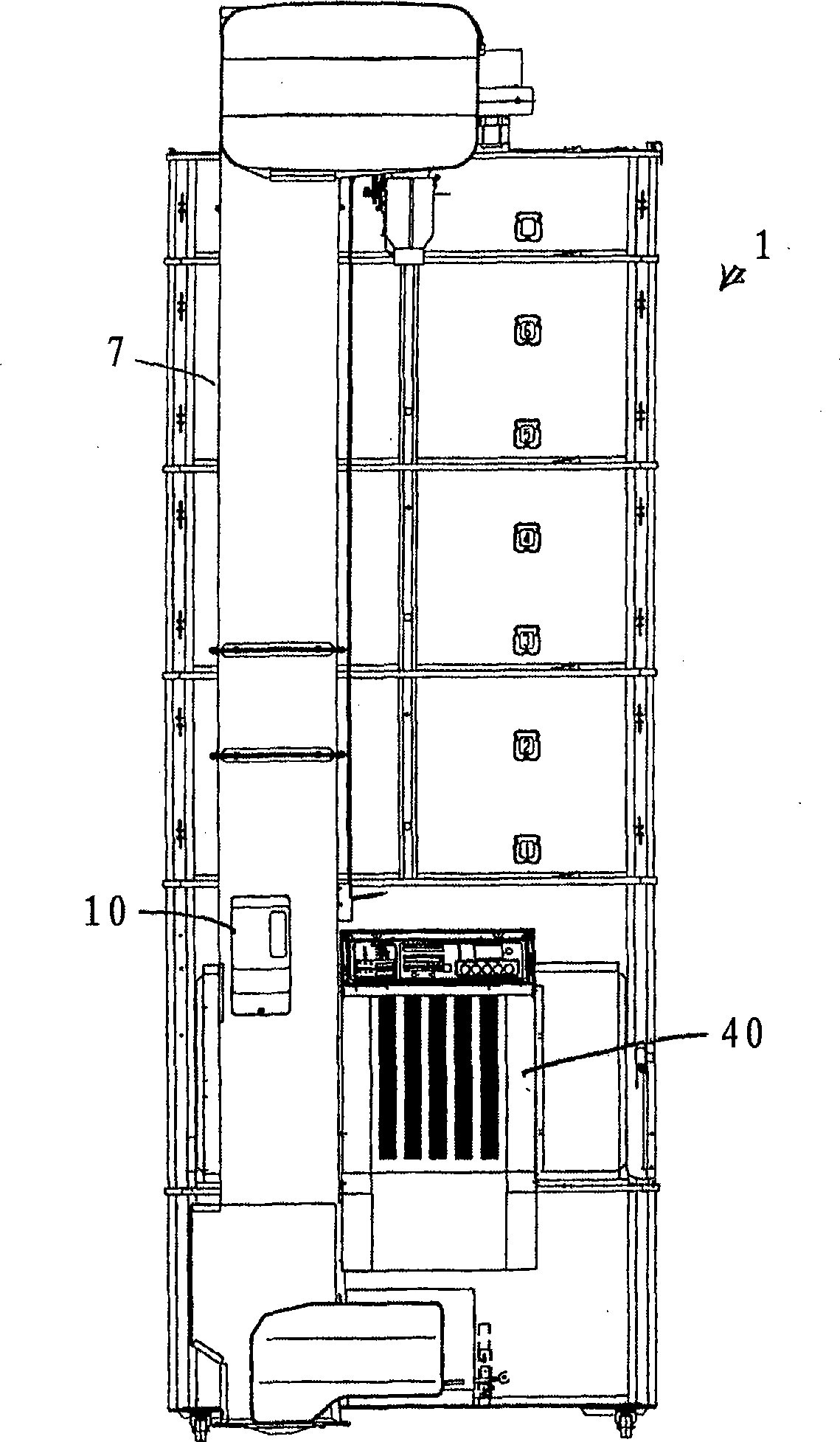

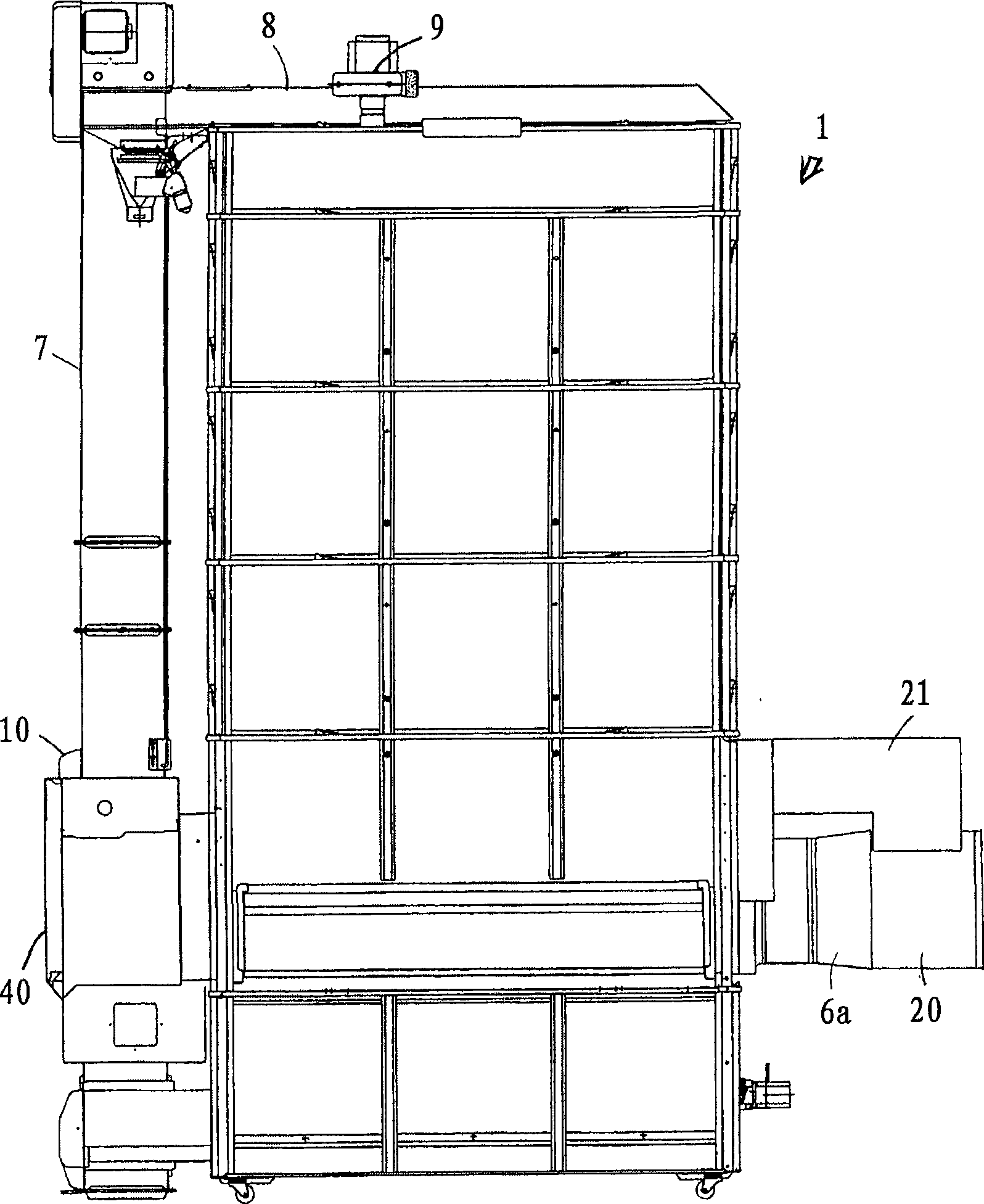

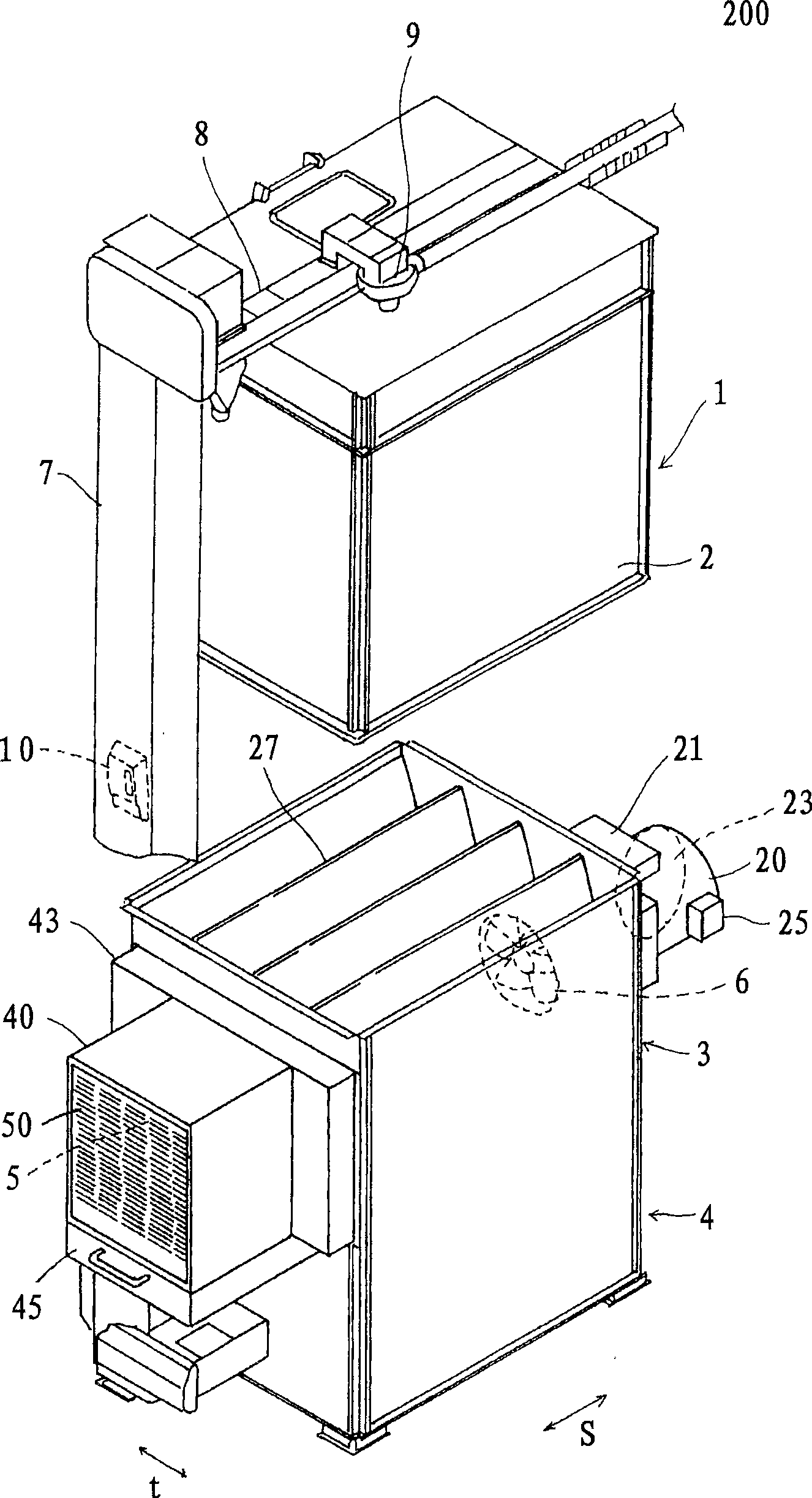

[0042]figure 1 , figure 2 It is figure showing the whole of grain dryer, image 3 It is a perspective view explaining the inside of a grain dryer. Inside the rectangular parallelepiped-shaped main body 1, there are provided in order from the top a storage section 2 for storing grains, a drying section 3 for drying the grains stored in the storage section 2 while flowing downward, and collecting and drying them in the drying section 3. The grain collection part 4 of the grain. And its structure has the structure of so-called circulation type grain dryer as follows: the grain that enters the storage part 2 is supplied to the grain collecting part 5 after being dried in the drying part 3, and is supplied to the storage part 2 again and conditioned. quality treatment.

[0043] In addition, in this embodiment, the longitudinal direction s of the main body 1 is called a front-back direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com