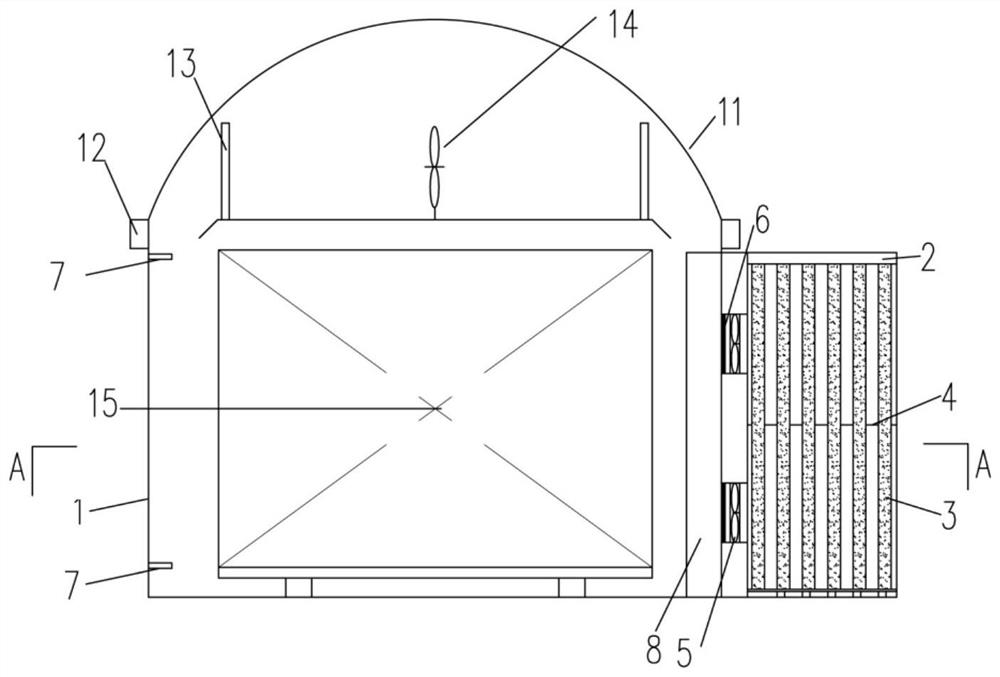

A drying device and method for continuously drying wood using solar energy

A solar drying and solar energy technology, applied in the direction of drying gas arrangement, local stirring dryer, static material dryer, etc., can solve the problems of inability to measure the heat storage of heat storage materials, provide energy, reduce moisture content gradient, etc., to avoid The effect of thermal pollution, energy saving and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

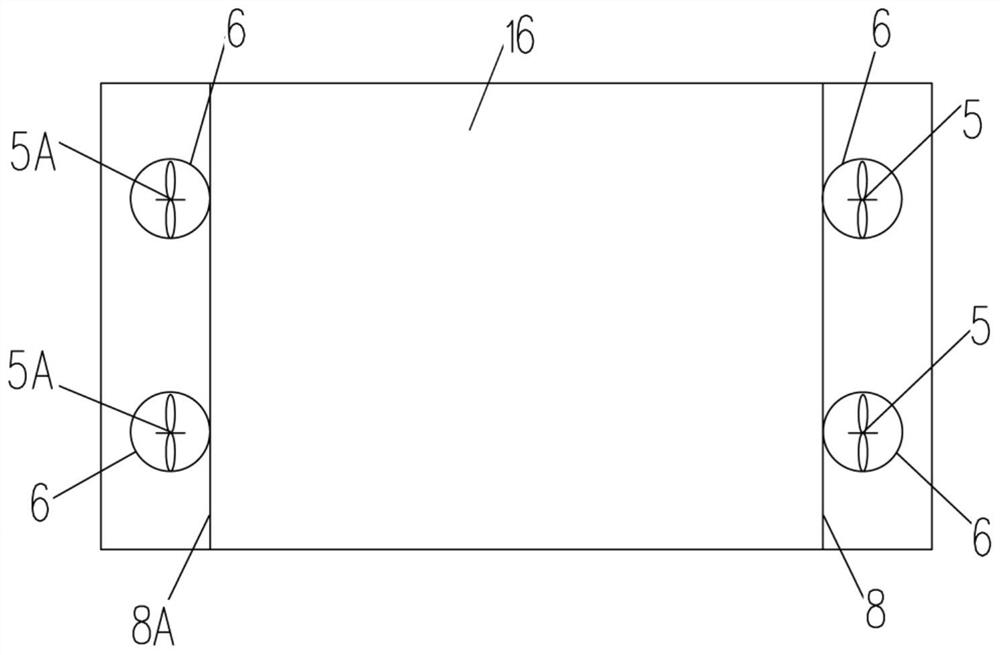

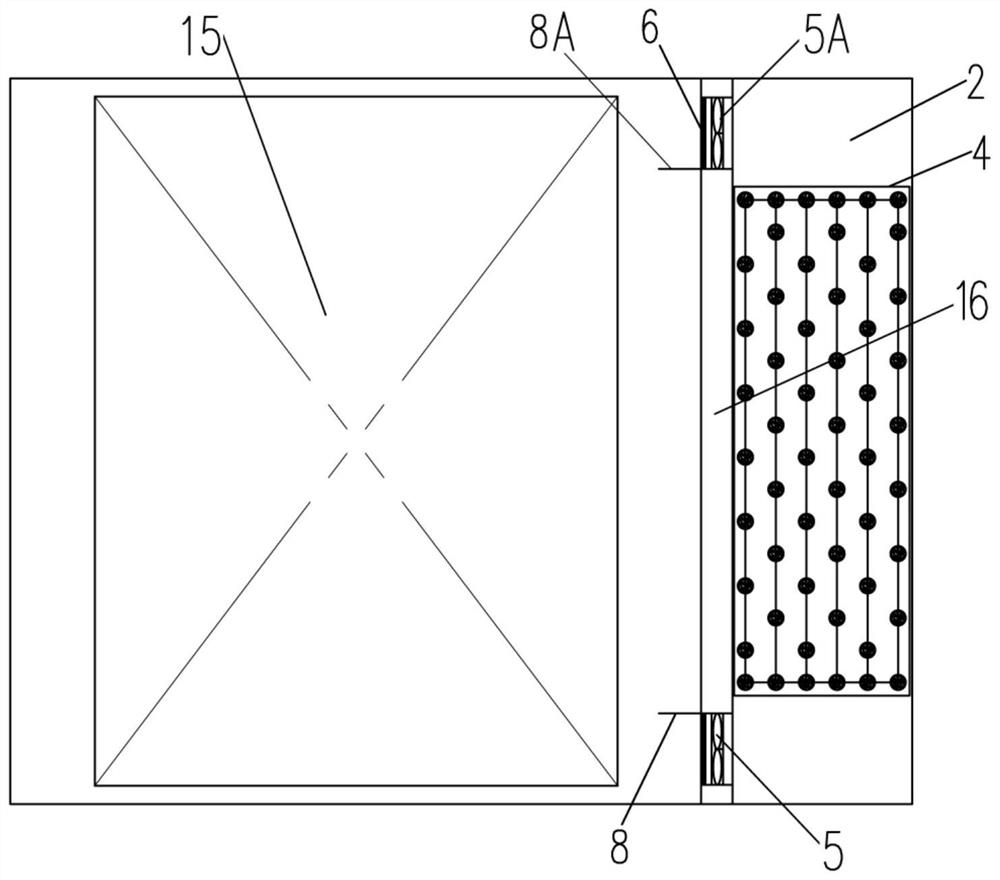

[0196] The present embodiment takes fir as an example to be described as the wood to be dried. Other woods such as poplar, fir, eucalyptus and other fast-growing materials, as well as hard broad-leaved materials such as ash and oak, are all applicable to the present invention; the drying kiln is constructed in Northern China is an example, wherein the length, width, and height of the solar drying kiln are 6m, 3m and 4m, and solar drying kilns of other sizes are also suitable for the present invention; the heat storage material is example with paraffin, and the phase change latent heat H of the paraffin is 177kJ / kg; other phase change heat storage materials are suitable for the present invention, such as stearic acid, polyethylene glycol, etc.

[0197] Check the autumn meteorological data of the location of the drying kiln to obtain the average temperature t of the location of the drying kiln in autumn 1 (25-35℃), average relative humidity (20-30%), so in this embodiment with...

Embodiment 2

[0260] Except for the t determined in step 6-3) in the evening ventilation process wh = 30°C, Calculating with k as 1.4, the minimum heat Q required for night kiln processing is obtained min =15084.8kJ; step 6-4) in the average temperature t of the phase change heat storage material xp is 55°C, the total heat Q stored in the heat storage system c is 9166.13kJ; Q during night kiln drying c ≤Q min , the heat stored in the heat storage system cannot meet the heat required for drying the stuffy kiln, then the drying kiln circulating fan and heater are turned on for auxiliary heating at night, and the auxiliary heating time τ at night is calculated according to formula (5),

[0261]

[0262] In formula (5), τ is the auxiliary heating time at night, h; Q min Total heat required for kiln drying, kJ; Q c is the heat stored in the heat storage material, kJ; P is the power of the auxiliary heater, W (watts).

[0263] Taking the power of the auxiliary heater as 2500W as an exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com