Ultra-low-carbon aluminum-killed steel vacuum carbon-loaded preliminary deoxidation process

A technology of aluminum killed steel and pre-deoxidation, which is applied in the field of metallurgy, can solve the problems of high consumption of aluminum shot and high content of inclusions, and achieve the effect of improving the purity of molten steel, reducing the content of inclusions, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

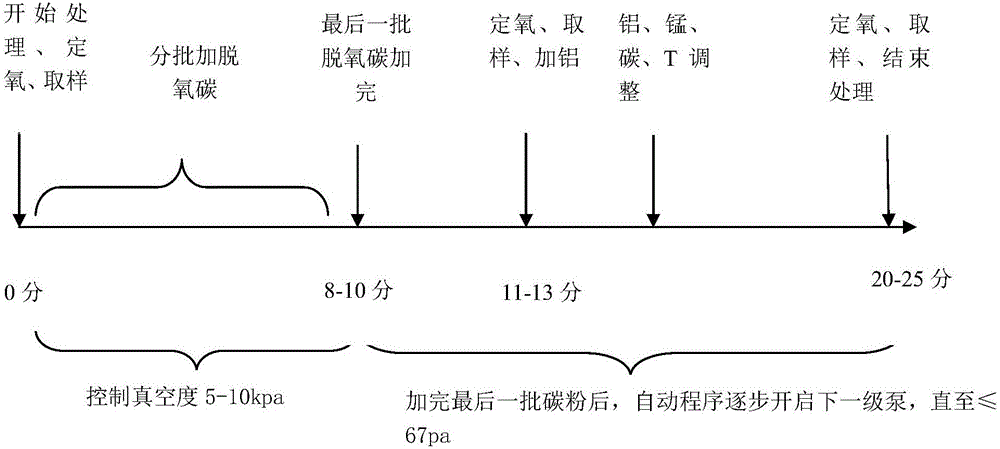

[0053] According to the above-mentioned ultra-low-carbon aluminum-killed steel vacuum adding carbon pre-deoxidation process, the specific steps are as follows: the molten steel reaches the vacuum treatment station to sample [O]671ppm, [C]410ppm, and the temperature is 1612℃:

[0054] 1) Calculate the amount of carbon added as 45.5kg, vacuum pump, add carbon powder in batches, add 20kg in the first batch for 5min, 20kg in the second batch in 7min, 5.5kg in the third batch in 9min, vacuum 6.7kpa;

[0055] 2) Gradually increase the vacuum degree to the ultimate vacuum degree ≤67pa, 12min fixed sample sampling [O]196ppm, [C]12ppm, add 202kg of aluminum pellets to deoxidize to the target, 23min treatment ends [C]13ppm, [O]18ppm. Temperature 1572 ℃; Compared with conventional aluminum pellets, the consumption is reduced by 0.2kg / t.

Embodiment 2

[0057] The molten steel arrives at the vacuum processing station for sampling [O]720ppm, [C]380ppm, temperature 1620℃:

[0058] 1) Calculate the amount of carbon added as 54.2kg, vacuum pump, add carbon powder in batches, add 20kg in the first batch in 5min, 20kg in the second batch in 7min, 14.2kg in the third batch in 9min, vacuum 8.1kpa;

[0059] 2) Gradually increase the vacuum degree to the ultimate vacuum degree ≤67pa, 12min fixed sample sampling [O]214ppm, [C]12ppm, add aluminum pellet 210kg deoxygenation to the target, 22min processing end [C]16ppm, [O]20ppm. Temperature 1576 ℃; Compared with conventional aluminum pellets, the consumption is reduced by 0.22kg / t.

Embodiment 3

[0061] Molten steel arrives at the vacuum processing station for sampling [O]862ppm, [C]362ppm, temperature 1634℃:

[0062] 1) Calculate the amount of carbon added as 91kg, vacuum pump, add carbon powder in batches, add 25kg in the first batch for 4min, 25kg in the second batch in 6min, 25kg in the third batch in 8min, and 16kg in the fourth batch in 10min. Vacuum 7.8kpa;

[0063] 2) Gradually increase the vacuum degree to the ultimate vacuum degree ≤67pa, 13min sample fixed sampling [O]226ppm, [C]12ppm, add 217kg aluminum pellets to deoxidize to the target, 24min treatment ends [C]15ppm, [O]21ppm. Temperature 1580 ℃; Compared with conventional aluminum pellets, the consumption is reduced by 0.24kg / t.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com