Device and method for disassembling square lithium ion batteries of multiple specifications

A lithium-ion battery, multi-standard technology, applied in battery recycling, chemical instruments and methods, transportation and packaging, etc., can solve problems such as poor adaptability, low efficiency, and inconsistent lithium-ion battery models, and achieve strong adaptability and automation High degree of accurate edge trimming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

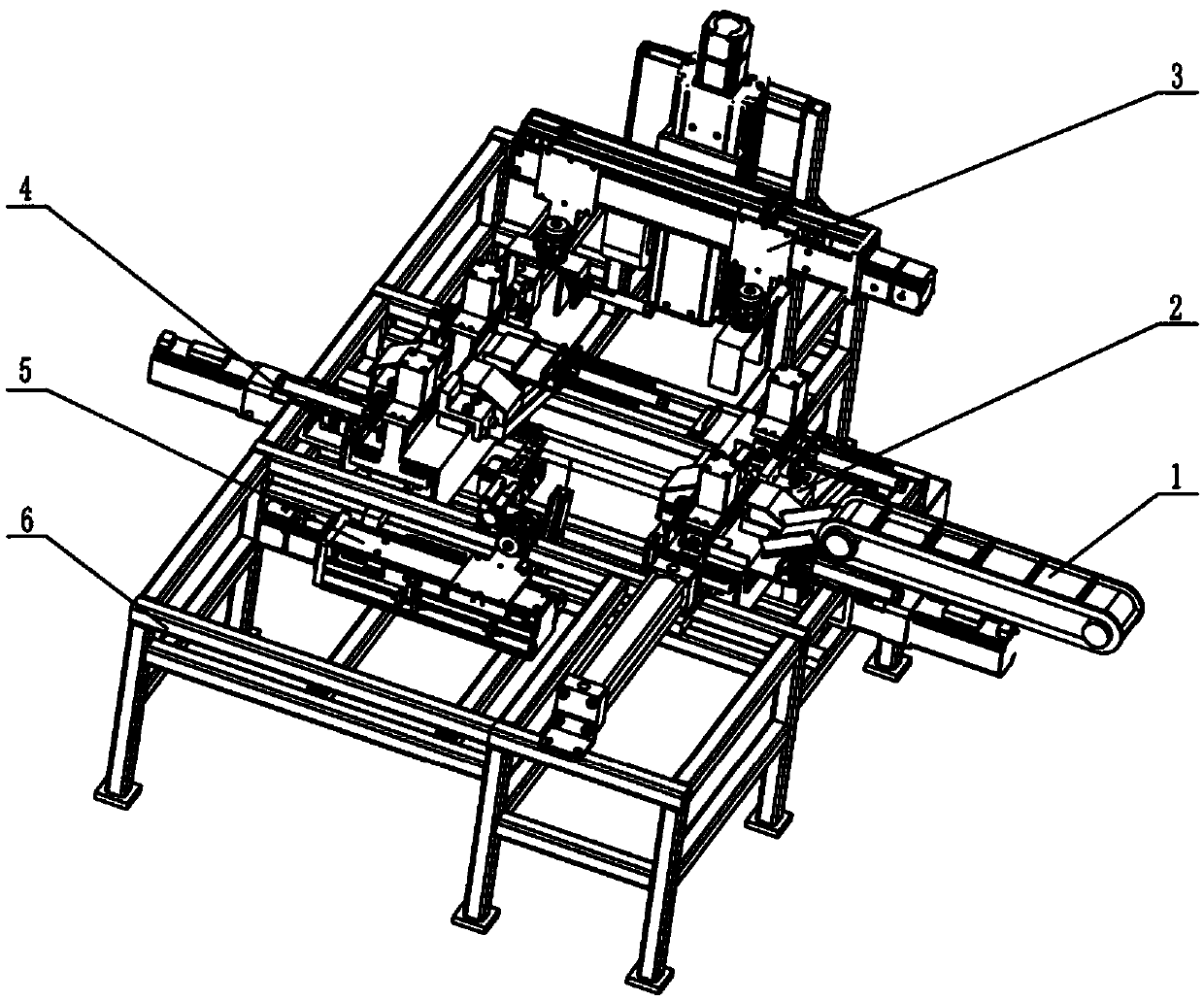

[0069] Such as Figure 1~12 As shown, a device adapted to the dismantling of multi-standard prismatic lithium-ion batteries,

[0070] Including: a control system and an assembly line dismantling system, the dismantling system includes: an intermittent feeding device 1 sequentially fixed on a frame 6 built of square steel, a No. 1 automatic edge trimming device 2, and a station conversion Device 3, No. 2 automatic edge trimming device 4 and separation coring device 5; the control system controls and disassembles each part of the system for assembly line operation: the intermittent feeding device 1 transports the waste ion battery to No. 1 automated edge trimming Device 2, the No. 1 automatic trimming device 2 completes the trimming action on the symmetrical sides of the waste lithium-ion battery, and the station conversion device 3 rotates the trimmed waste lithium-ion battery by 90 degrees and transports it to the No. 2 automatic trimming device 4. No. 2 automatic trimming de...

Embodiment 2

[0101] A method of adapting to the dismantling of multi-standard prismatic lithium-ion batteries, using the device described in Embodiment 1 to adapt to the disassembly of multi-standard prismatic lithium-ion batteries, comprising the following steps:

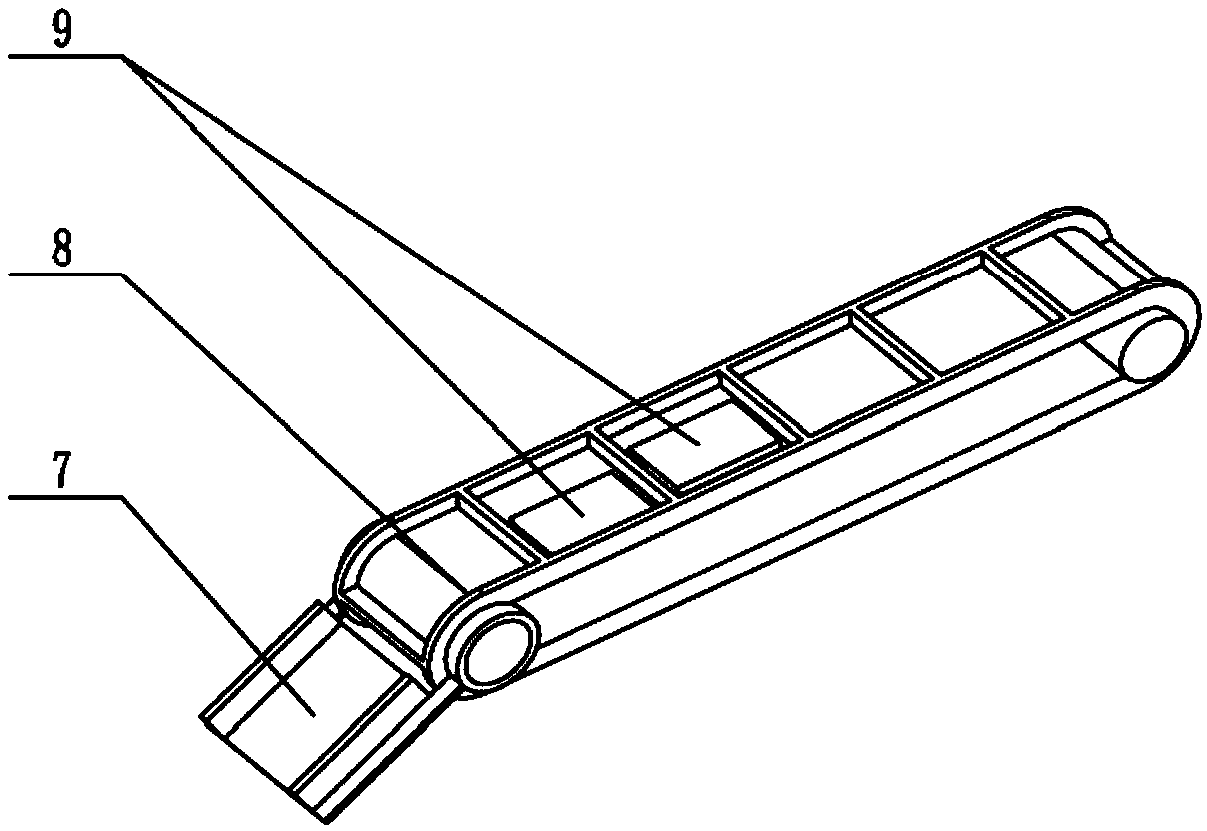

[0102] 1) Place a batch of square waste lithium-ion batteries 9 containing different sizes and specifications directly into the figure 2 In the shown separate space of the feeding conveyor belt 8 provided with baffles, the feeding is carried out by the intermittent feeding control system in conjunction with the knife-cutting and dismantling speed;

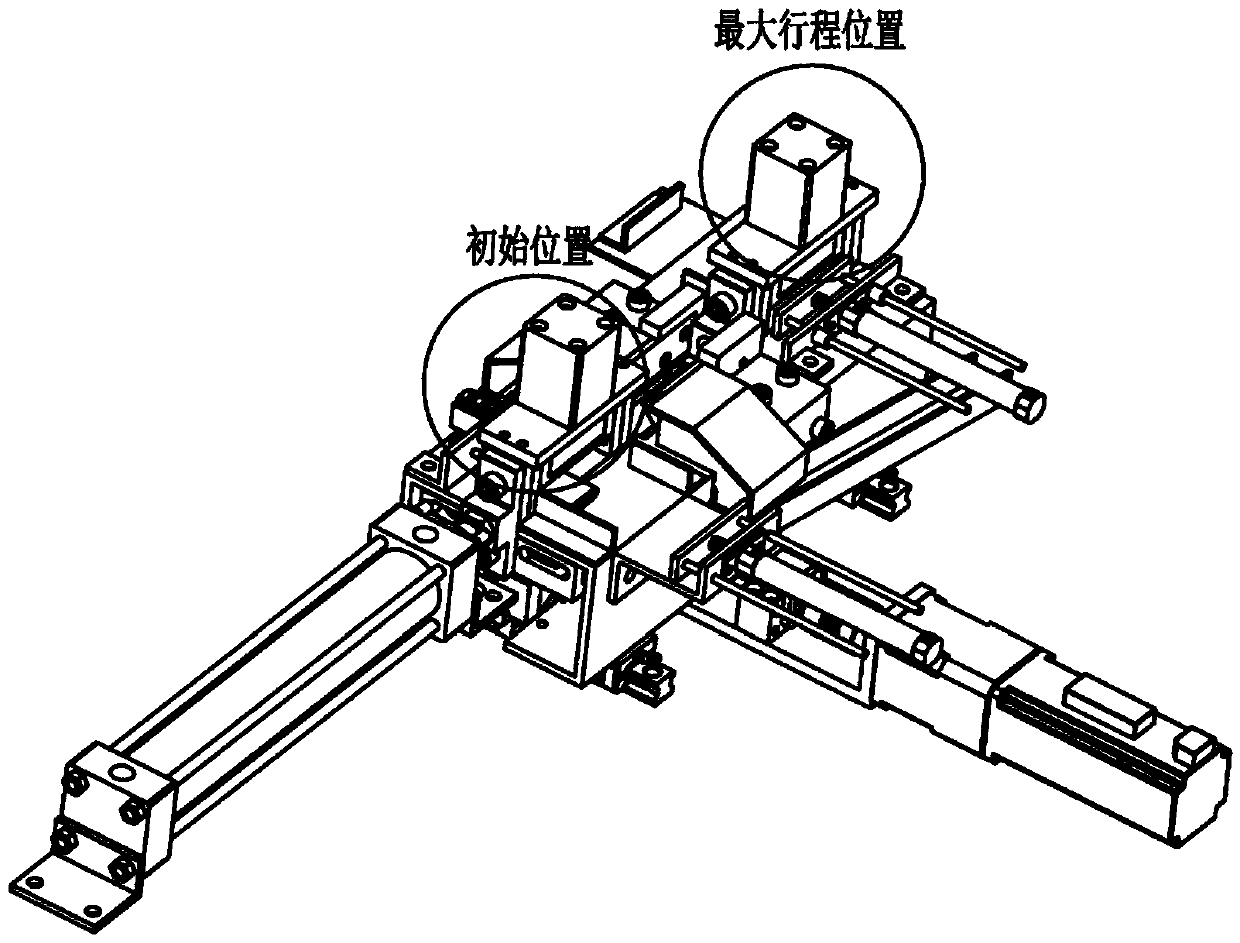

[0103] 2) The waste lithium-ion battery first slides down through the feeding chute 7 onto the No. 1 distance-adjusting platform 14 in the No. 1 automatic trimming device 2, and the Figure 4 The distance measuring cylinder 10, the blocking cylinder 11 and the limit stop bar 12 in the feeding distance measuring device shown in the figure perform push positioning and distance measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com