Patents

Literature

60results about How to "Does not reduce adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

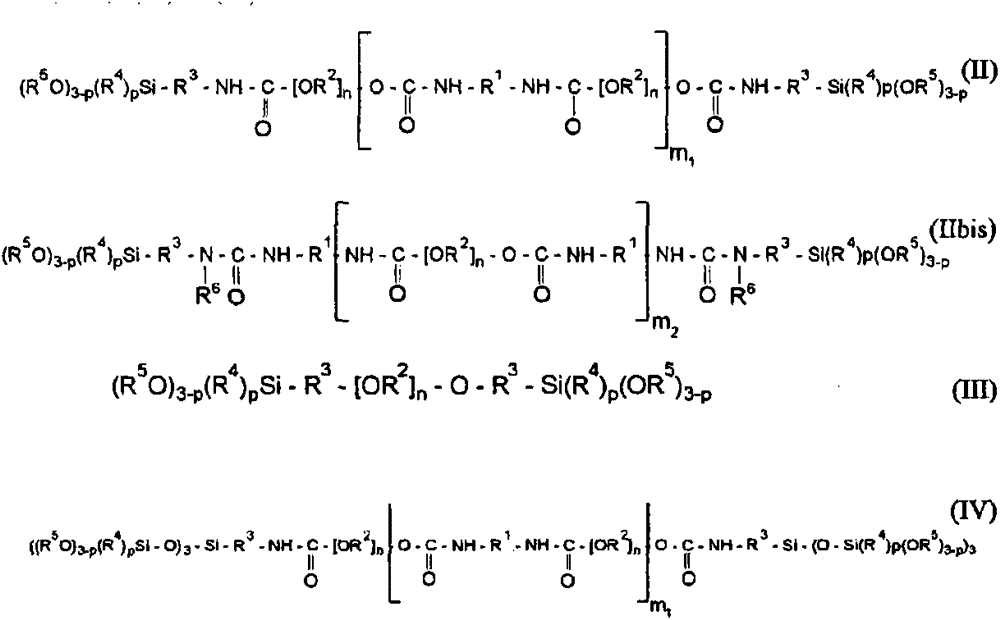

Double-component silane-terminated sealing adhesive and preparation method thereof

InactiveCN102304340AFlexible ratio rangeFlexible dosageOther chemical processesPolyureas/polyurethane adhesivesEndcappingPolymer science

The invention discloses a double-component silane-terminated seal adhesive which comprises a component A and a component B, wherein the component A is prepared from silane-terminated prepolymer, plasticizer, thixotropic agent, ultraviolet absorbent, ultraviolet stabilizer, moisture remover, accelerator, curing agent, colorant, bulking filler and reinforcing filler; the component B is prepared from silane-terminated prepolymer, plasticizer, cocatalyst, surfactant and water absorbent; and the component A and the component B are mixed in a weight ratio of 5:1-49:1. In the invention, the proportioning range of the double-component system is more flexible, and the consumption of the component B is flexible and low, so that the properties of the double-component system are closer to and even superior to those of the single component A in the curing process after reducing the A\B mixture.

Owner:TONSAN ADHESIVES INC

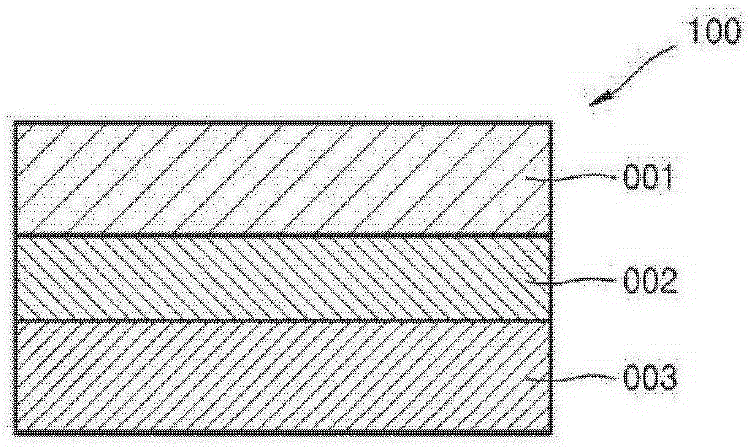

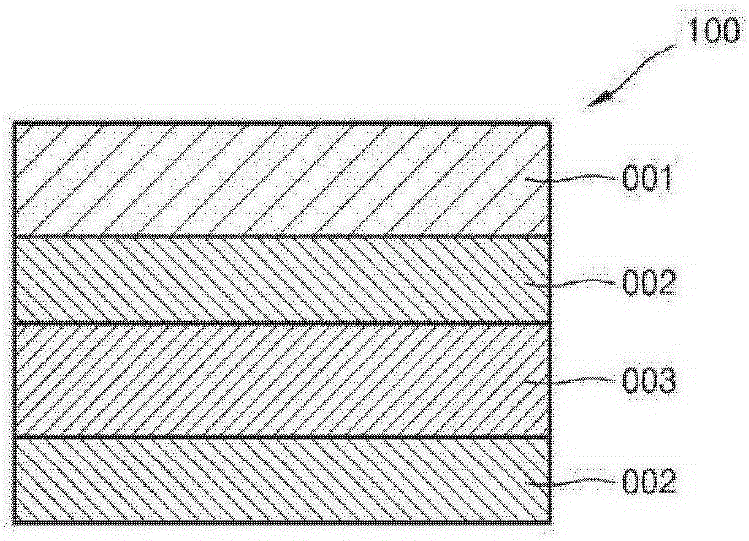

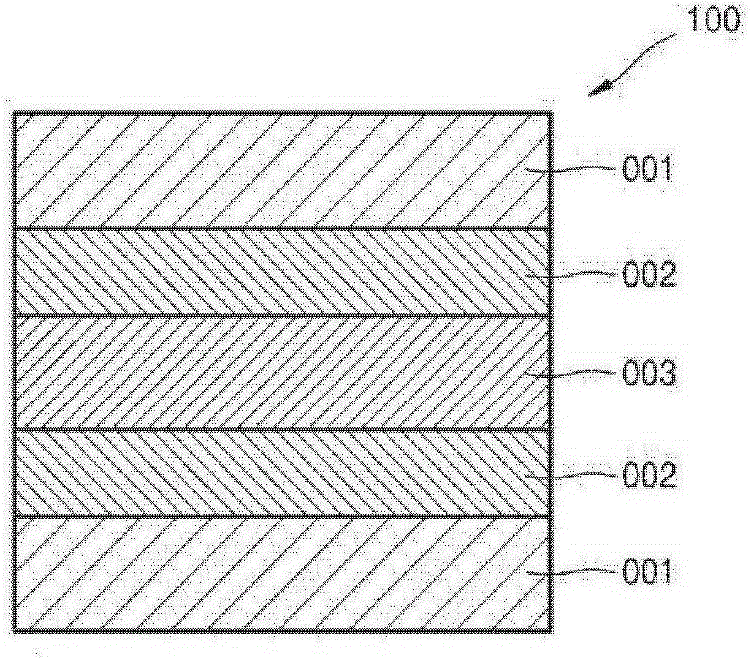

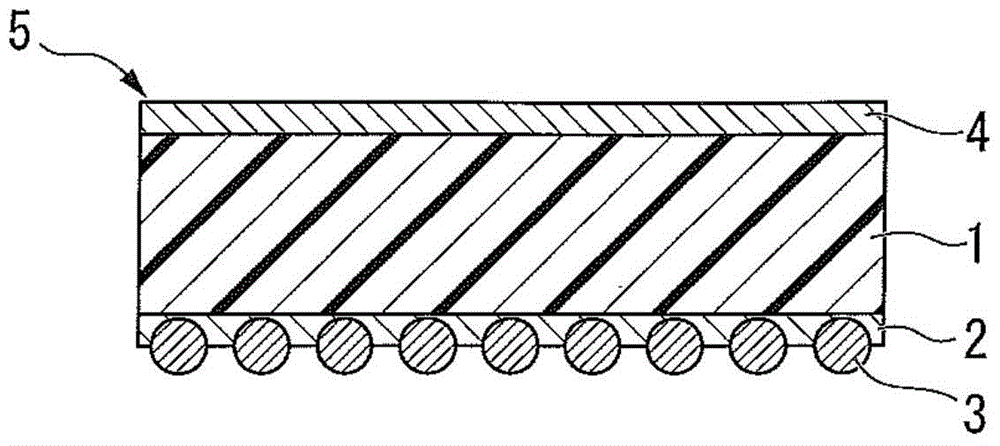

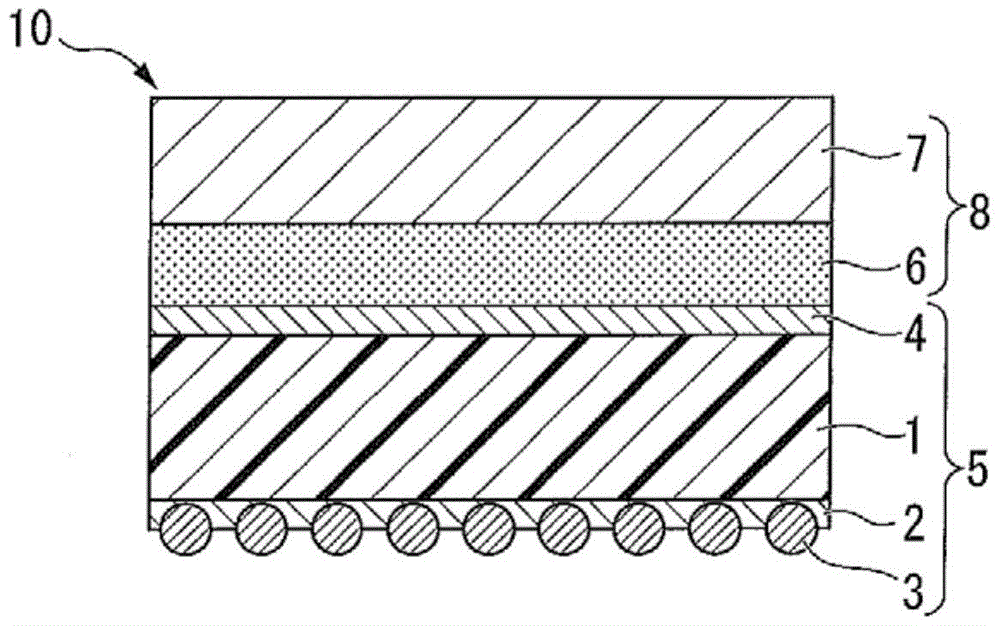

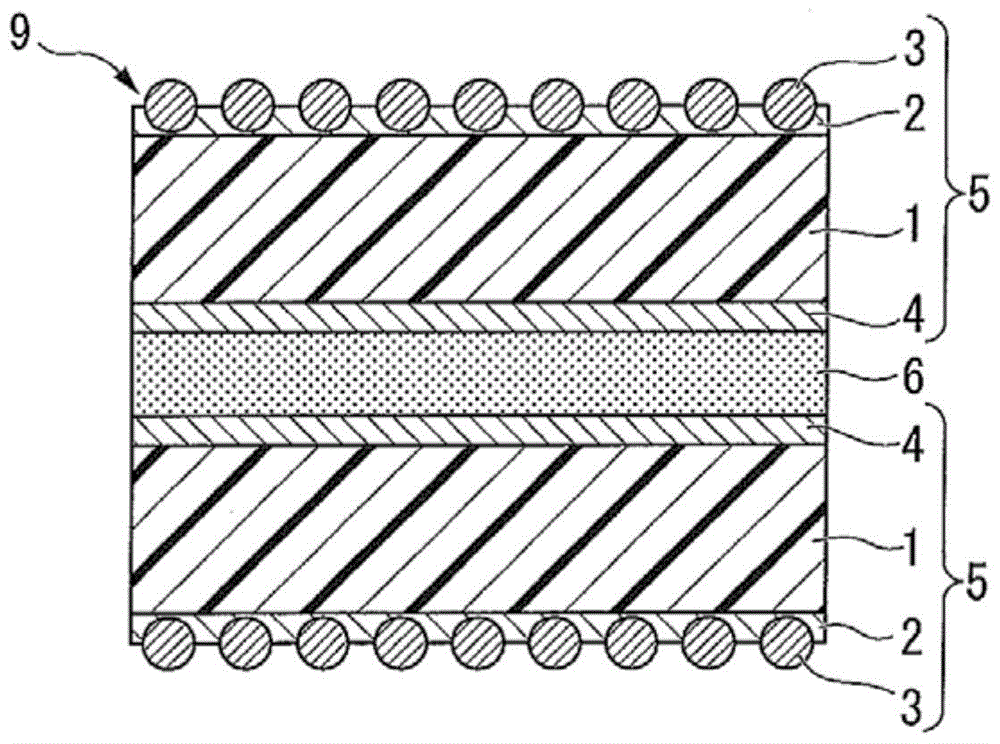

Conductive heat-dissipating sheet, and electrical parts and electronic devices comprising same

InactiveCN105325067AExcellent thermal diffusion performanceExcellent electromagnetic wave shielding performanceMagnetic/electric field screeningSemiconductor/solid-state device detailsHeat sinkMetallic materials

Disclosed herein are a conductive heat-dissipating sheet comprising a heat diffusion layer formed using metal materials; a heat conduction layer which is disposed on one surface or both surfaces of the heat diffusion layer and which is formed using inorganic materials including at least one material from the group consisting of metal oxides and alloys; and an adhesive layer disposed on one surface or both surfaces of the heat conduction layer; and an electrical part and an electronic device comprising the conductive heat-dissipating sheet.

Owner:ILJIN MATERIALS CO LTD

Ultraviolet ray/anaerobic dual curing binding agent and preparation method thereof

InactiveCN101392151ALow efficiencyImprove performanceOrganic non-macromolecular adhesiveAdhesiveUltraviolet

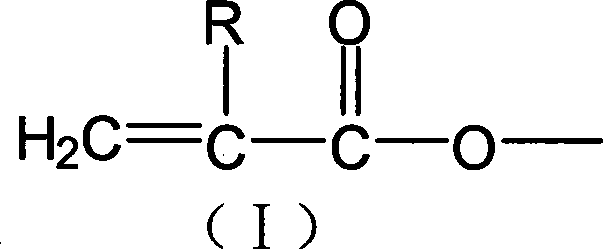

The invention discloses an ultraviolet / anaerobic double-curing adhesive which comprises components with the following parts by weight: altogether 100 portions of monomer or oligomer comprising vinyl or a mixture of both, 0.01 portion to 0.5 portion of inhibitor, 0.1 portion to 10 portions of photo-initiator and an appropriate portion of anaerobic-adhesive initiator; the anaerobic-adhesive initiator comprises components with the following weight portions: 0.05 portion to 5 portions of organic hydrazide, 0.05 portion to 5 portions of tertiary amine, 0.01 portion to 2 portions of ascorbic acid, 0 portion to 1 portion of ascorbate, 0.1 portion to 5 portions of saccharin, 0 portion to 1 portion of saccharin salt, 0.5 portion to 5 portions of organic salt and 0.5 portion to 10 portions of organic peroxide. The invention also provides a preparation method of the adhesive, which comprises the steps as follows: the other components, except the organic peroxide and the photo-initiator, are mutually blended for dissolution by the conventional method; then the photo-initiator is added and dissolved; and the organic peroxide is added and mixed evenly at the temperature below 40 DEG C, and finally the adhesive is prepared. The adhesive has not only highly efficient anaerobic curing performance, but also excellent adhesive performance as an ultraviolet curing adhesive, with wide application prospect.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

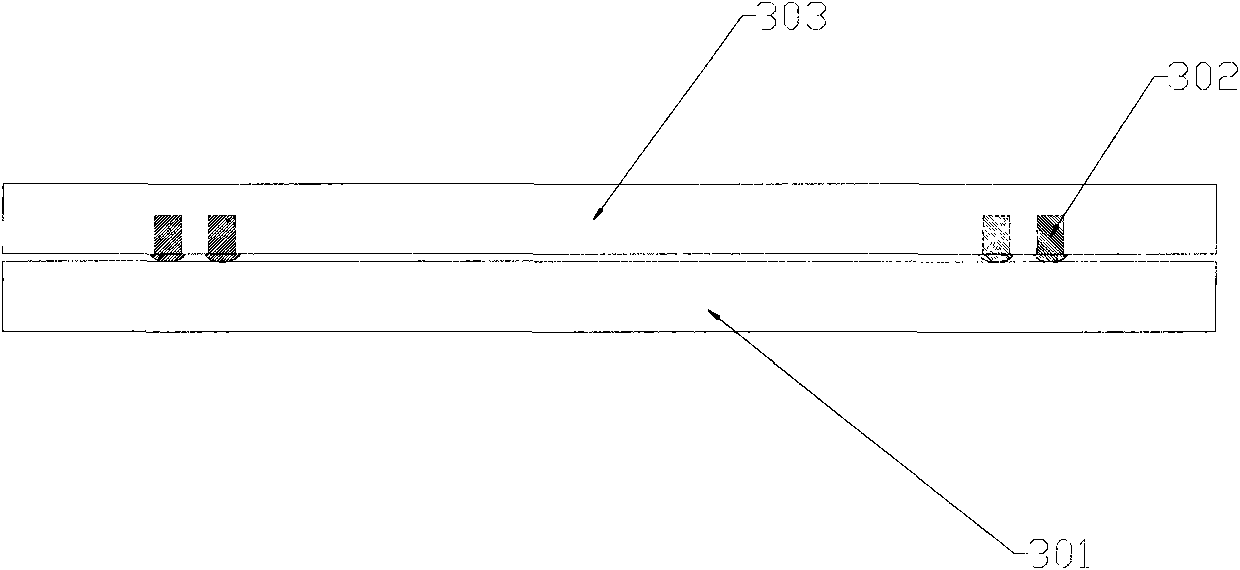

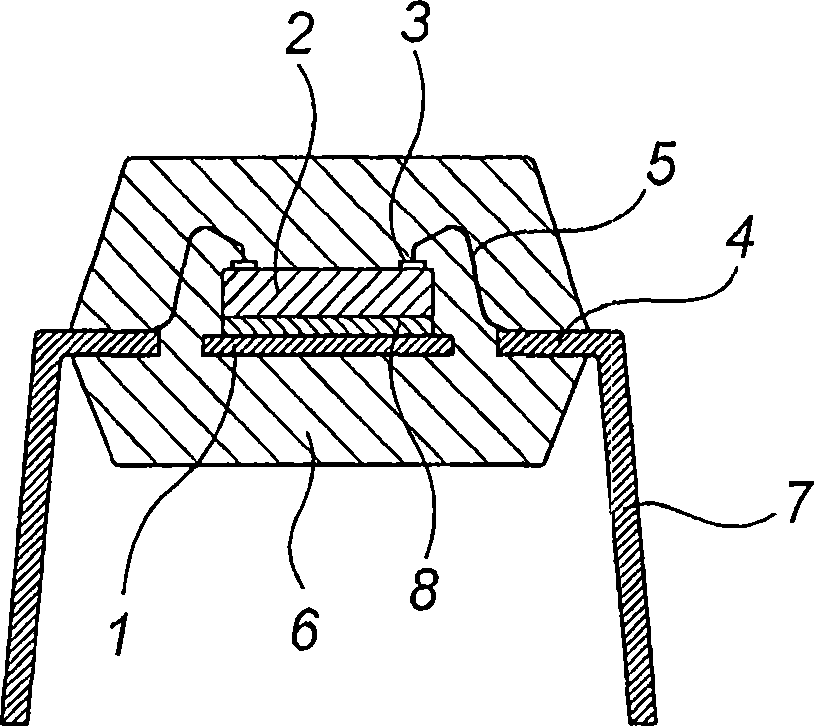

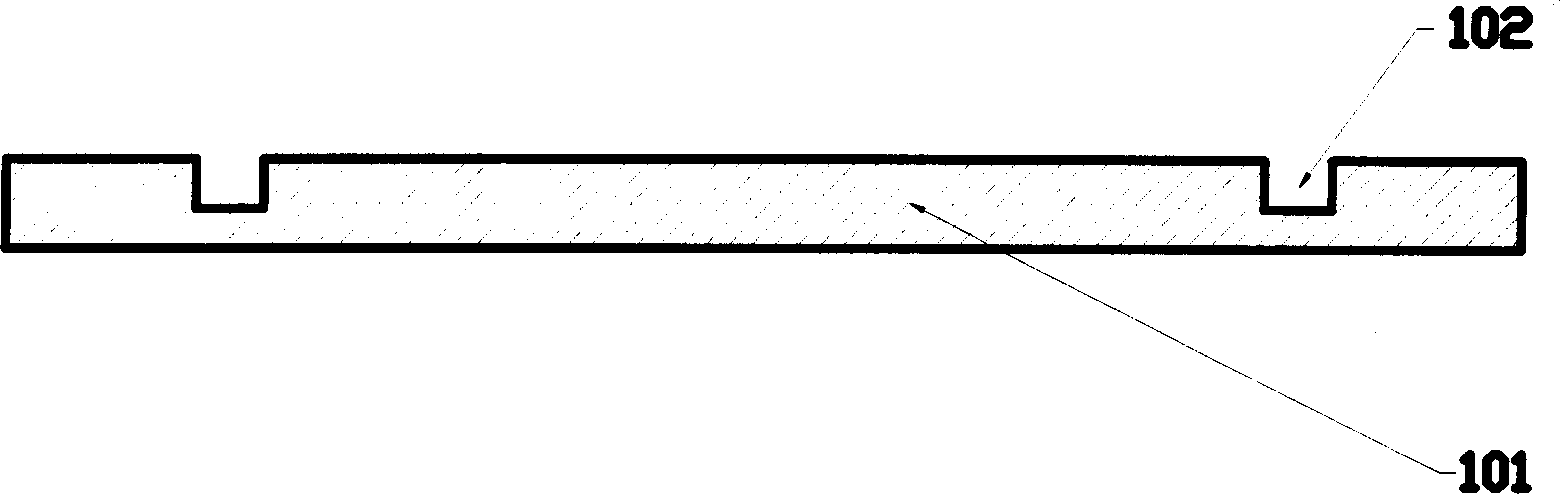

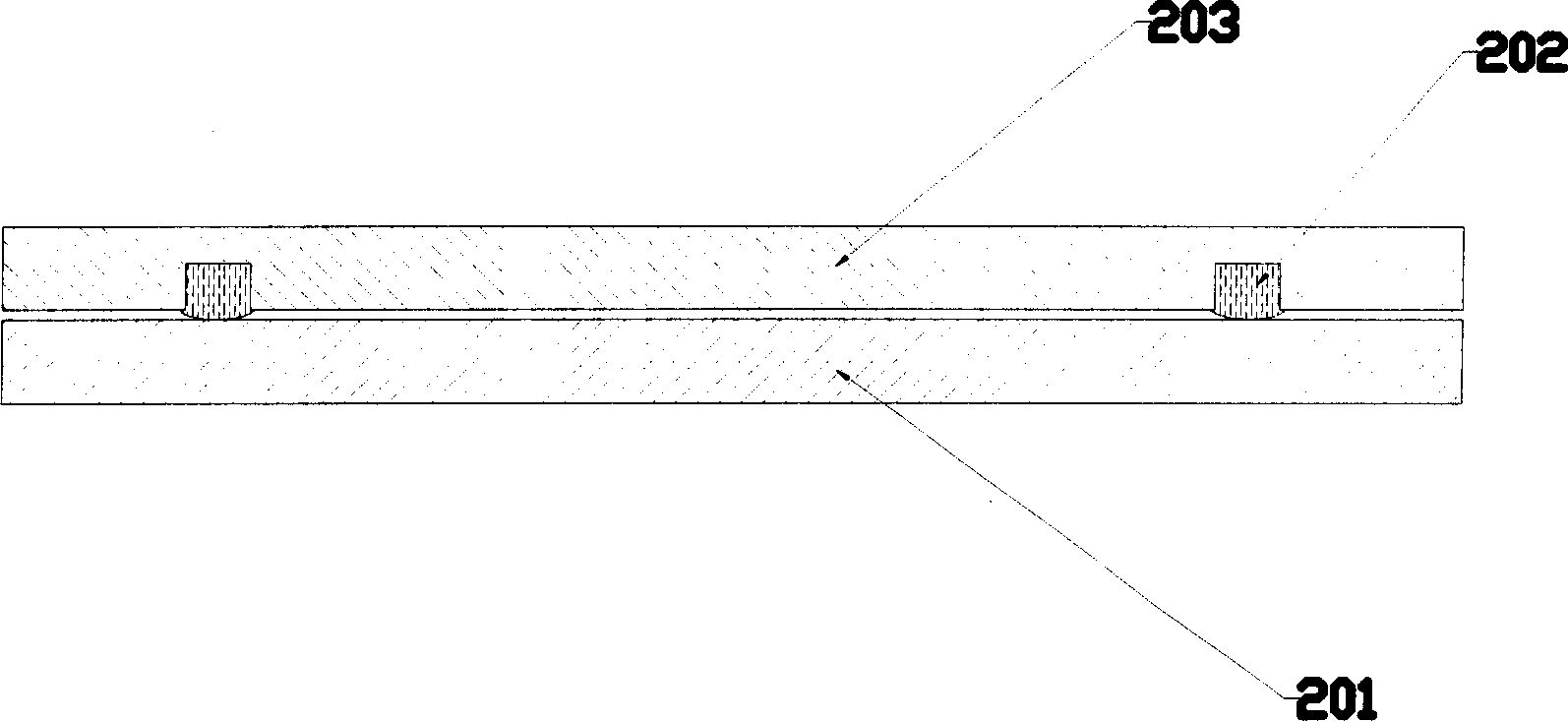

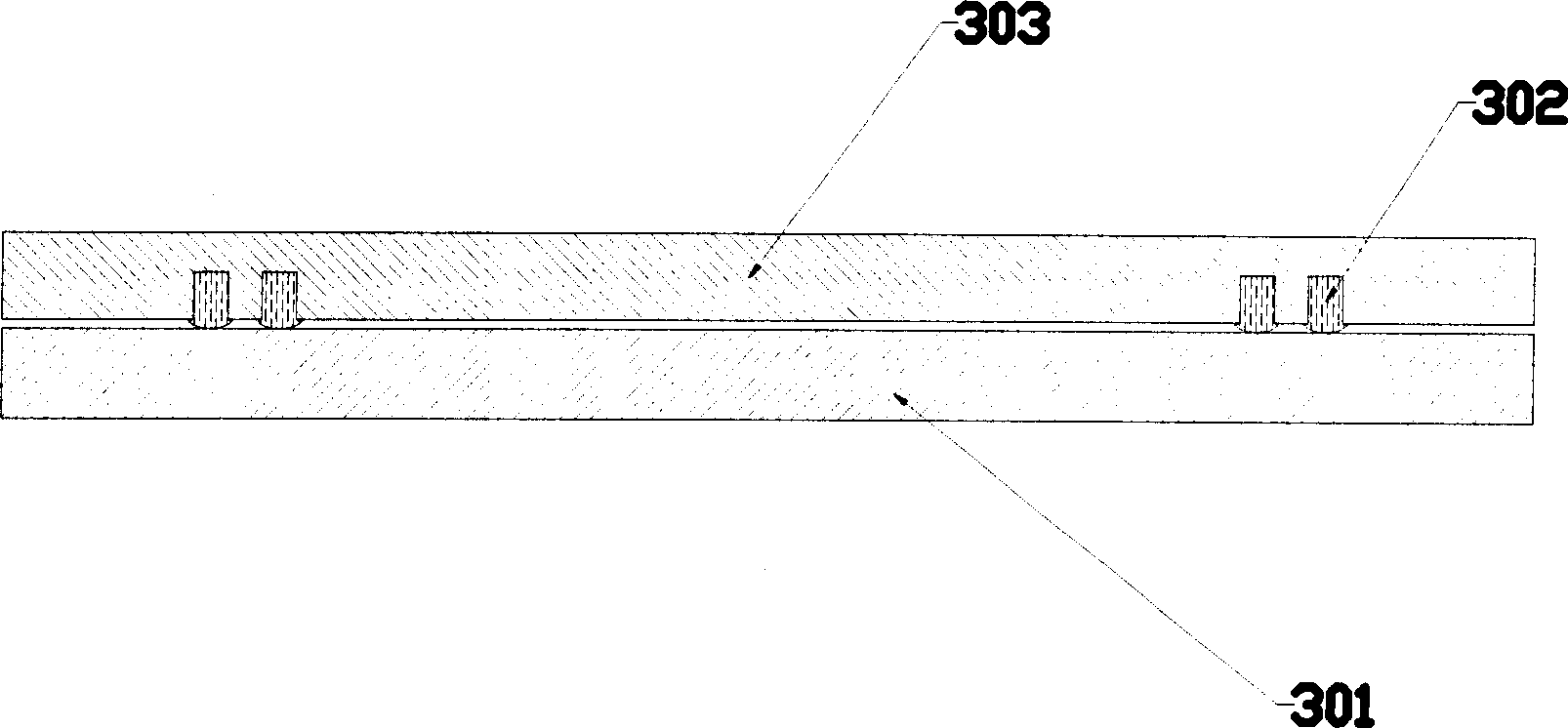

Packaging housing of humidity-sensitive electronic device, substrate and leakproof structure thereof

ActiveCN101572253AReduce stickingReduce thicknessTelevision system detailsImpedence networksEngineeringOrganic electroluminescence

The invention relates to a packaging housing of a humidity-sensitive electronic device, a substrate and a leakproof structure thereof. In the premise that the thickness of leakproof material is not reduced, the thickness of the leakproof material contacted with the environment is reduced. The packaging housing of the humidity-sensitive electronic device and / or the edge of the substrate contains a round of or more rounds of grooves used for being poured into the leakproof material. The humidity-sensitive electronic device can be an organic electroluminescence device, a micro-machine electrical sensor and a charge coupled device sensor. by manufacturing the grooves on the substrate of the device and / or the packaging housing, the invention pours the leakproof material into the grooves, thus reducing the thickness of the leakproof material contacted with the environment in the premise that the thickness of leakproof material is not reduced, achieving the technical effects of not reducing the adhesive property of the substrate and the packaging housing and increasing the packaging effect; when a plurality of grooves exist, better adhesive property and packaging effect exist.

Owner:GUAN YEOLIGHT TECH CO LTD +1

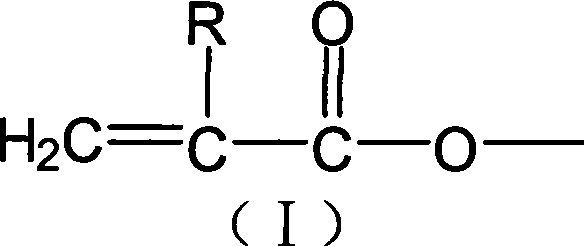

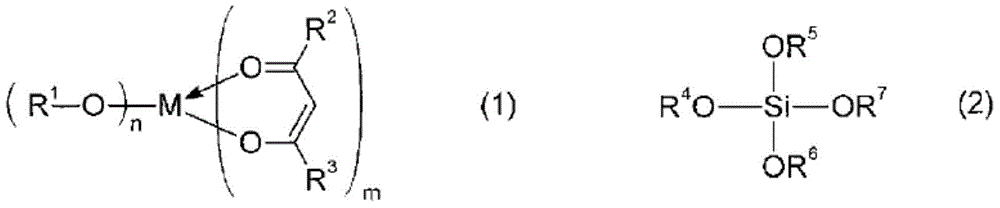

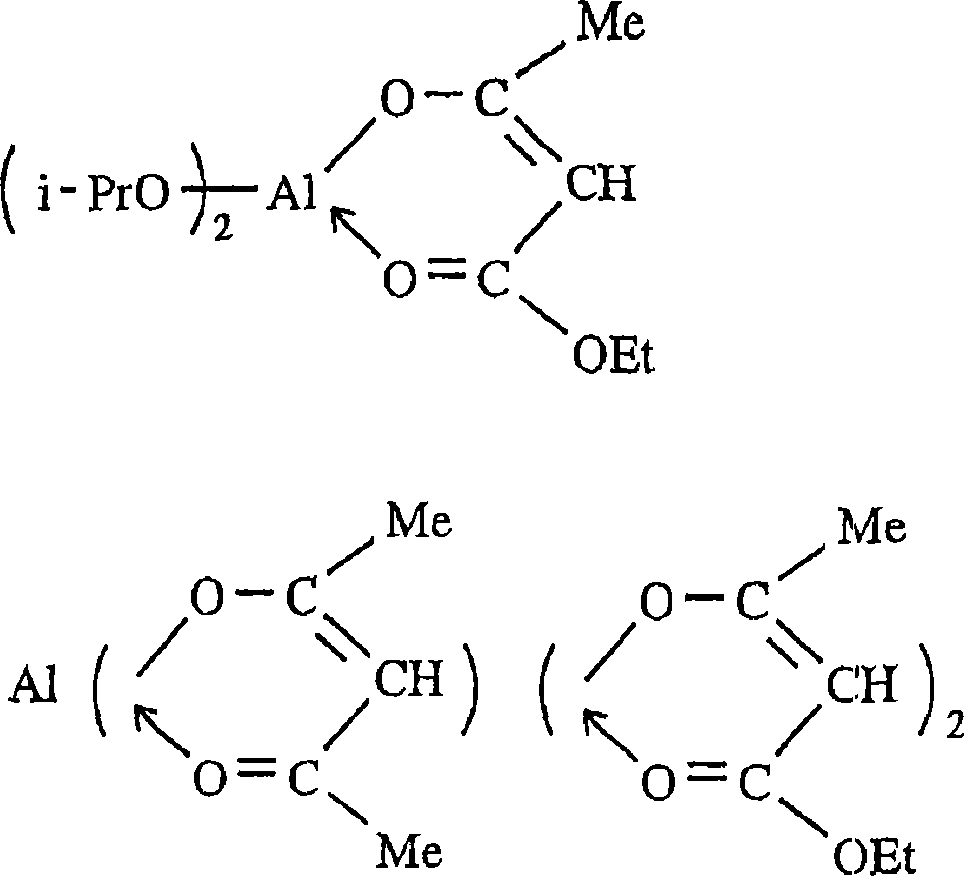

Photosensitive resin composition, protection film or insulation film, touch panel and method for manufacturing same

InactiveCN105122137AExcellent adhesionGood chemical resistancePhotosensitive materials for photomechanical apparatusInput/output processes for data processingTectorial membraneHigh resistance

The purpose of the present invention is to provide an alkali developable photosensitive resin composition which has multiple performances, i.e., being capable of providing a cured film that has high hardness, high transparency, high resistance to moist heat, high adhesiveness and high chemical resistance, and, when stored in the form of a coating solution, showing high storage stability and the adhesiveness and chemical resistance thereof not being deteriorated during storage. Provided is a photosensitive resin composition comprising: an alkali-soluble resin (A); a metal chelate compound (D); and a silane compound (E), wherein the alkali soluble resin (A) is an alkali soluble resin having a double bond equivalent within a specific range, the metal chelate compound (D) is a compound having a specific structure, and the silane compound (E) is a tetrafunctional silane or silane oligomer having a specific structure.

Owner:TORAY IND INC

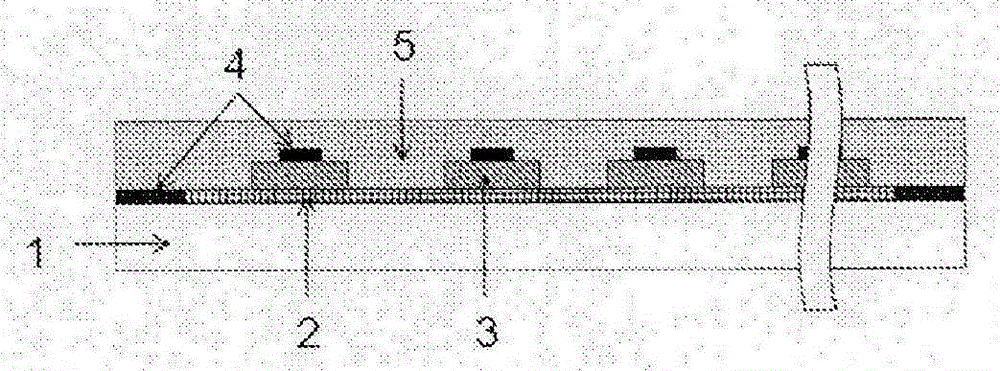

Release film having excellent peelability

ActiveCN105950041AExcellent peelabilitySmall peeling forceSynthetic resin layered productsCellulose adhesivesPolymer sciencePeel force

The present invention provides a release film excellent in peelability. The release film has a small peeling force, which is not liable to increase with a lapse of time even in a state that the release film adheres to an adhesive layer; the transfer of a silicone component to the adhesive layer is less, and the adhesive force of the adhesive layer to which the film adheres is not reduced. The release film excellent in peelability is characterized in that a release agent layer (4) having a thickness of 0.4 to 2 [mu]m and containing a silicone-based release agent is provided on one surface of a base film (1), and an adhesive resin layer (2) containing inorganic fine particles and / or polymer particles as fine particles (3) are arranged on the other surface of the base film; the fine particles (3), the adhesive resin layer (2) and the release agent layer (4) satisfy the following conditions (1) and (2): (1) the volume reference average particle size of the fine particles (3) is more than twice the thickness of the release agent layer (4); (2) the thickness of the adhesive resin layer (2) is in the range of 25 to 60% of the volume reference average particle size of the fine particles (3).

Owner:FUJIMORI KOGYO CO LTD

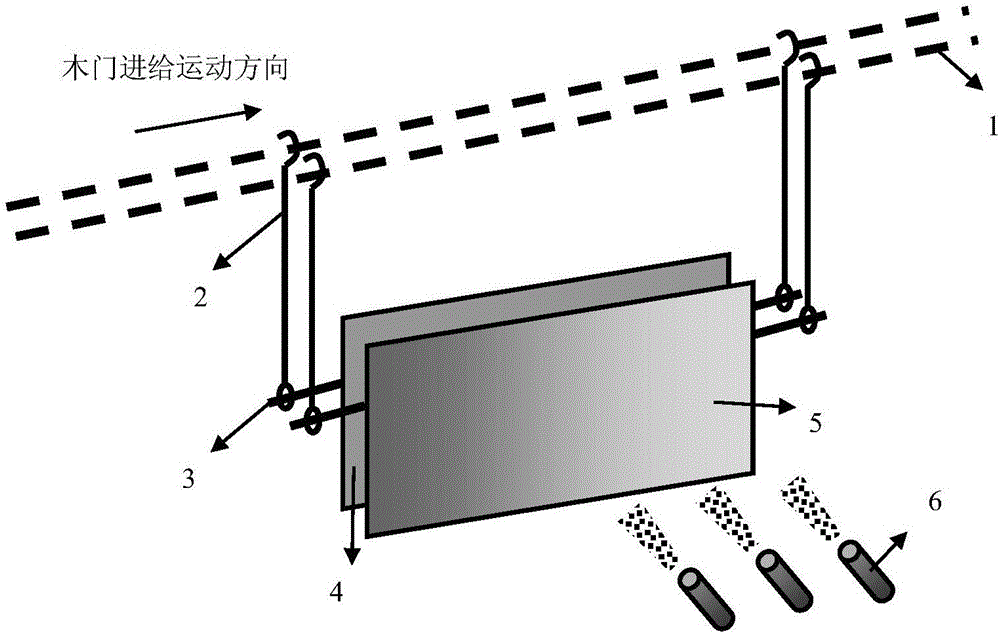

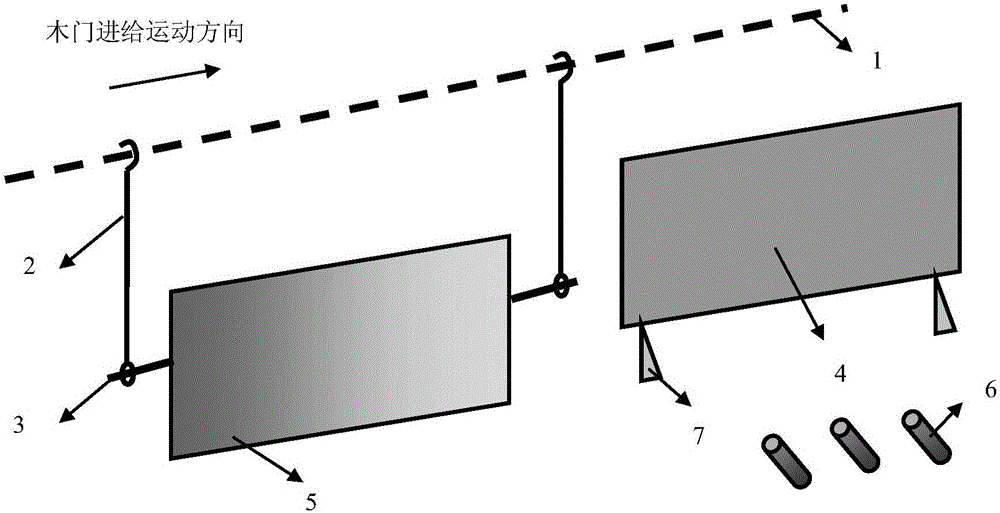

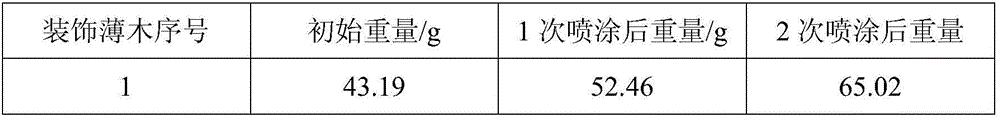

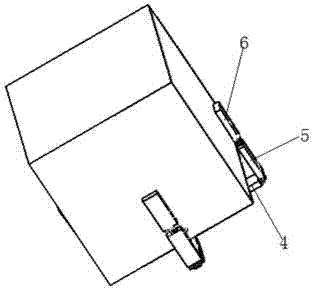

Method for improving quality of electrostatic surface coating of wooden door

ActiveCN106391428ADoes not reduce adhesionImprove the quality of electrostatic sprayingLiquid surface applicatorsCoatingsMechanical engineeringSurface coating

The invention discloses a method for improving the quality of an electrostatic surface coating of a wooden door. The method for improving the quality of the electrostatic surface coating of the wooden door comprises the steps that the wooden door is prepared; and spraying is conducted, specifically, a grounding conductive board is adopted to be placed on the back side of the wooden door during spraying, and in the electrostatic spraying process, the wooden door is located between an electrostatic spraying gun and the grounding conductive board. By adoption of the method for improving the quality of the electrostatic surface coating of the wooden door, the problems that in the conventional electrostatic spraying process of the wooden door, the thickness of a coating is nonuniform, the painting rate is instable, and painting is difficult during secondary spraying or finish paint spraying can be solved; and meanwhile, no humidification treatment needs to be conducted on the surface of the wooden door, so that the adhesive force of a paint film is not reduced, and the electrostatic spraying quality is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

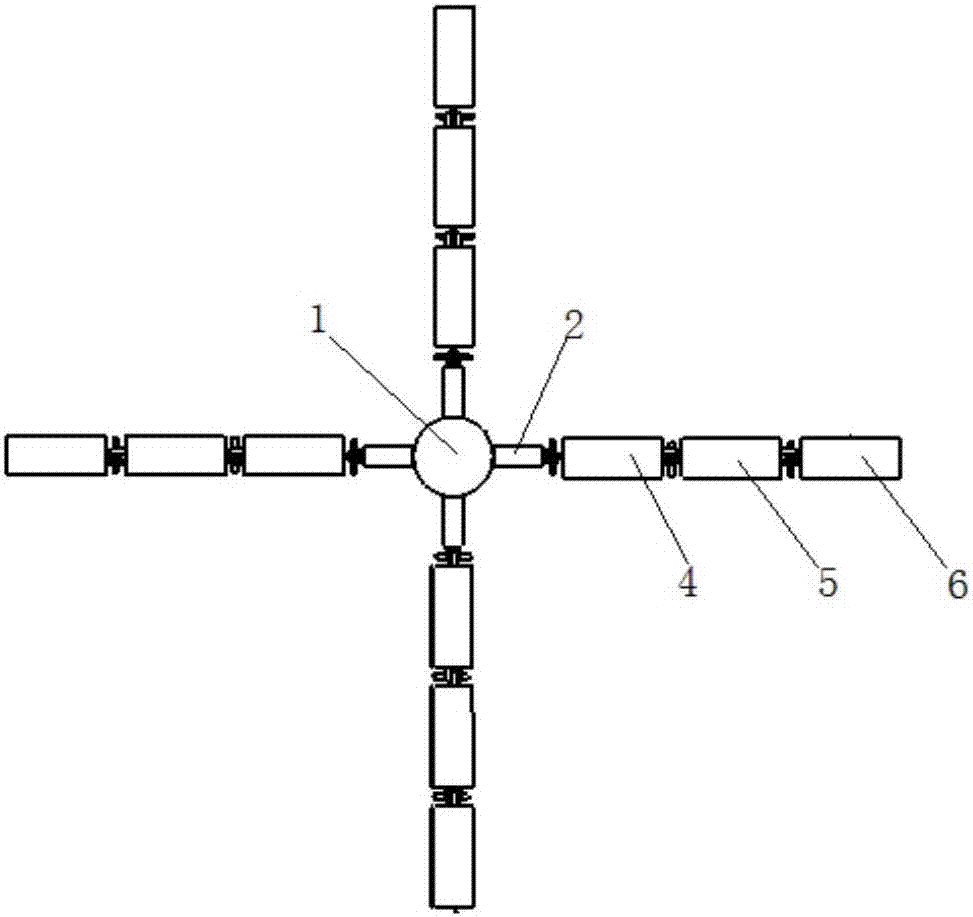

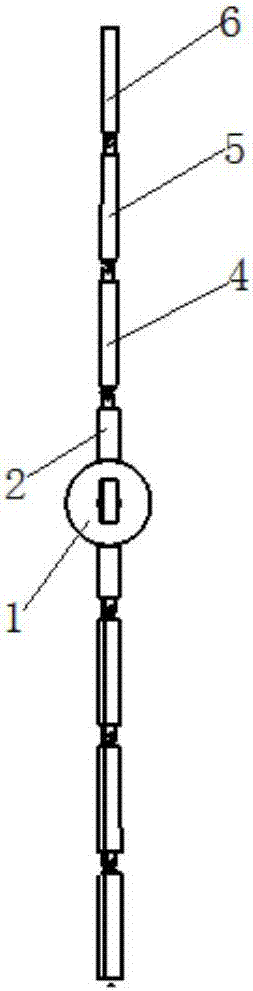

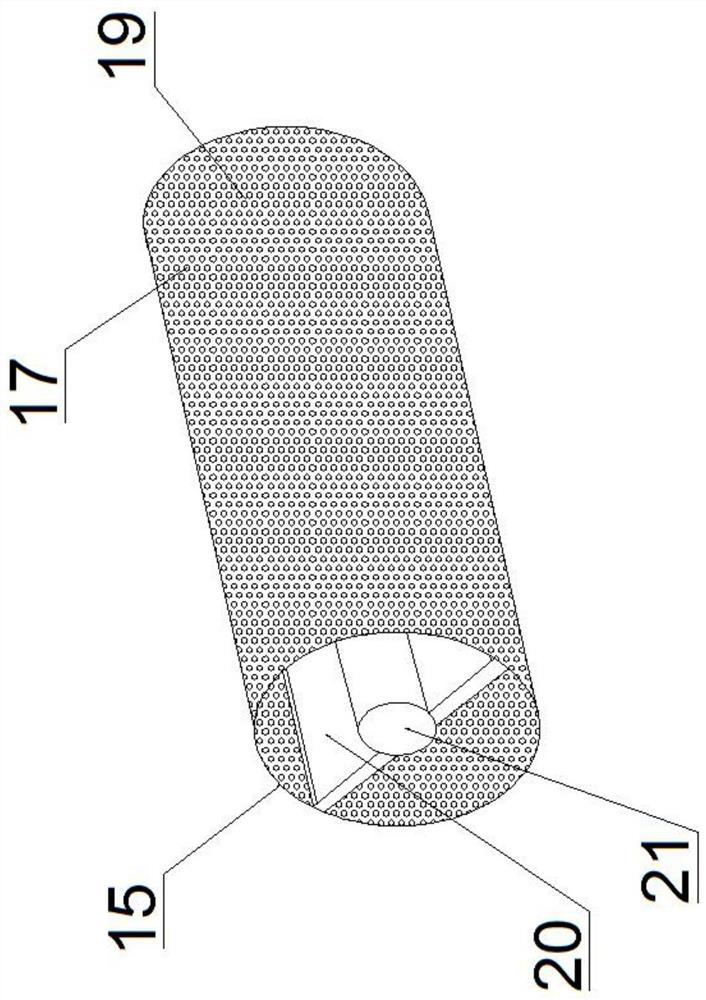

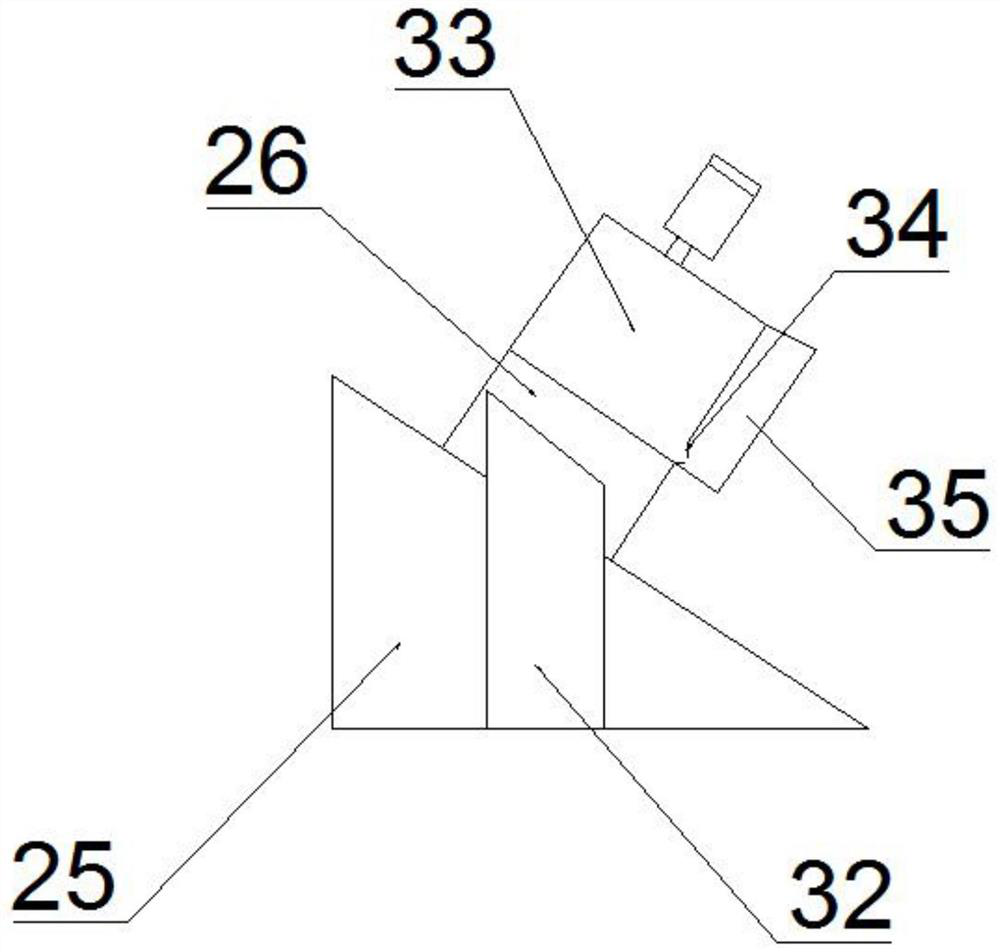

Under-actuated space capturing mechanism and method

ActiveCN107199558AImprove adhesionGood applicability in shape and sizeProgramme-controlled manipulatorToolsEndurance capacityHinge angle

The invention discloses an under-actuated space capturing mechanism and method. The mechanism comprises a ball-shaped hinge and four branched mechanism bodies; each branched mechanism body is connected with the ball-shaped hinge through a first worm, and the four branched mechanism bodies are arranged at intervals; two motors are perpendicularly arranged in the ball-shaped hinge, and the first worms are sleeved with the motors; and each motor is used for driving the two corresponding branched mechanism bodies located on the same line, and an adhesion plate is arranged on each branched mechanism body and used for capturing. According to the size of a target, the motor in the ball-shaped hinge and the motor in the second adhesion plates are selected to conduct driving, and whole capturing is completed; the motors are started or stopped according to requirements, and energy is saved; and in capturing, aiming at target bodies of different types and sizes, the motor in the ball-shaped hinge and the motor in the second adhesion plates are started or stopped correspondingly, the energy is saved, reinforcement of the endurance capacity is facilitated, the complex requirements for controlling in the original capturing process are reduced, and the whole method is simple and easy to implement and control.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Dendritic polymer dispersant-added waterborne coating ink

The invention relates to dendritic polymer dispersant-added waterborne coating ink and belongs to the field of coatings. The waterborne coating ink comprises the following components in parts by weight: 1-3 parts of dendritic polymer, 80-150 parts of waterborne resin, 8-12 parts of toner and 11-22 parts of a solvent. The waterborne coating ink has the beneficial effects that 1, the industrial production is achieved, the process is simple and the batch promotion can be achieved; 2, the property of the coating can be increased, the process effect is improved and such mechanical properties of the coating as adhesive force, flexibility, hardness, wear resistance and the like cannot be decreased; 3, the waterborne coating ink can be universal for dispersion of azo and quinacridone organic pigments, compared to conventional dispersants, the dendritic dispersant disclosed by the invention has significant advantages of final evaluation indicators, namely, viscosity and fineness over the conventional dispersants, the addition is less than those of the conventional dispersants, the overall advantages are prominent and purposes that the cost is saved and the process effects is improved can be achieved.

Owner:WEIHAI CY DENDRIMER TECH +1

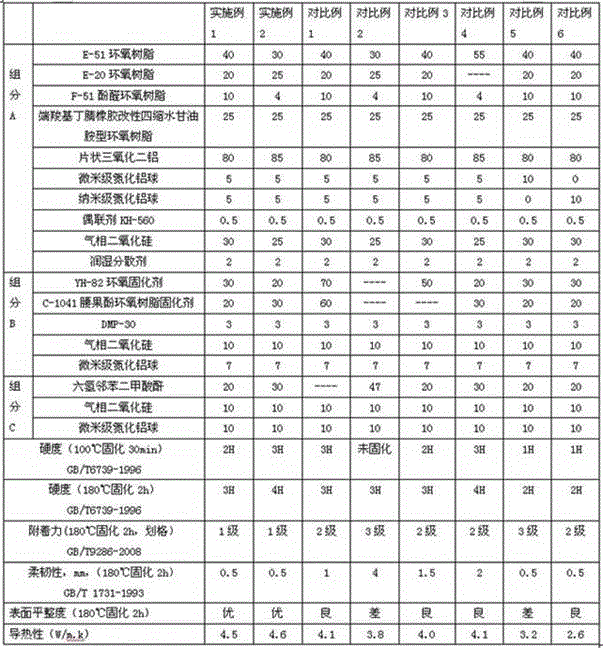

High temperature-resistant step-cured epoxy paint and application method thereof

ActiveCN103319984AImprove high temperature resistanceImprove interface adhesionEpoxy resin coatingsHexahydrophthalic anhydrideGas phase

The invention discloses a high temperature-resistant step-cured epoxy paint and an application method of the paint. The high temperature-resistant step-cured epoxy paint is obtained by mixing ingredient A, ingredient B and ingredient C in A certain proportion, wherein the ingredient A is an epoxy resin ingredient and comprises E-20 bisphenol A epoxy resin, E-51 bisphenol A epoxy resin, F-51 phenolic aldehyde epoxy resin, carboxylate-terminated nitrile butadiene rubber modified tetraglycidylamine type epoxy resin, aluminum oxide, aluminum nitride, fumed silica, a wetting dispersant, and a coupling agent; the ingredient B is a first curing agent ingredient and comprises an YH-82 epoxy curing agent, a C-1041 anacardol epoxy resin curing agent, DMP-30, fumed silica, and aluminum nitride; and the ingredient C is a second curing agent ingredient and comprises hexahydrophthalic anhydride, fumed silica, and aluminum nitride. The high temperature-resistant step-cured epoxy paint disclosed by the invention can be pre-cured at low temperature, does not form an unsmooth paint film, is cured at a high temperature, and remains the advantages of high strength and good adhesive force of the paint film which is cured at a high temperature.

Owner:广东顺召涂料有限公司

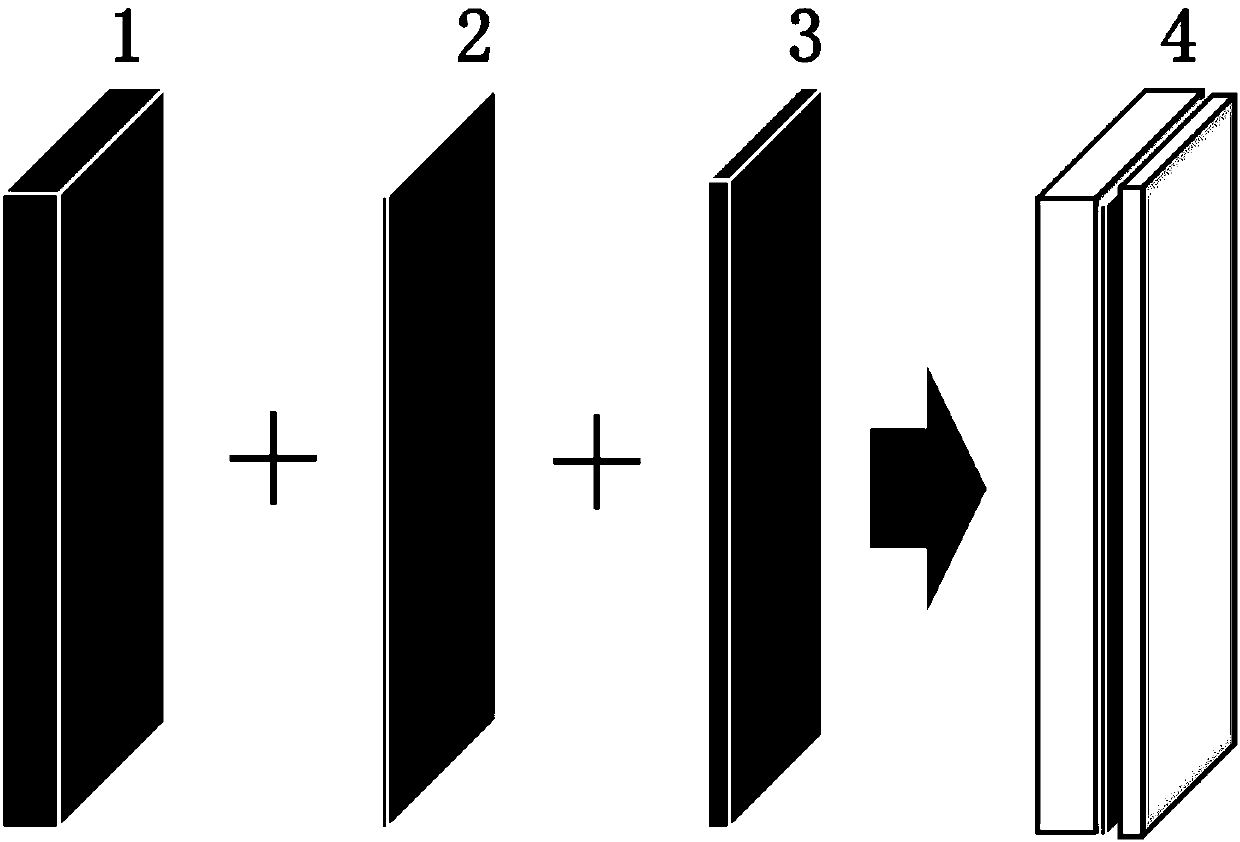

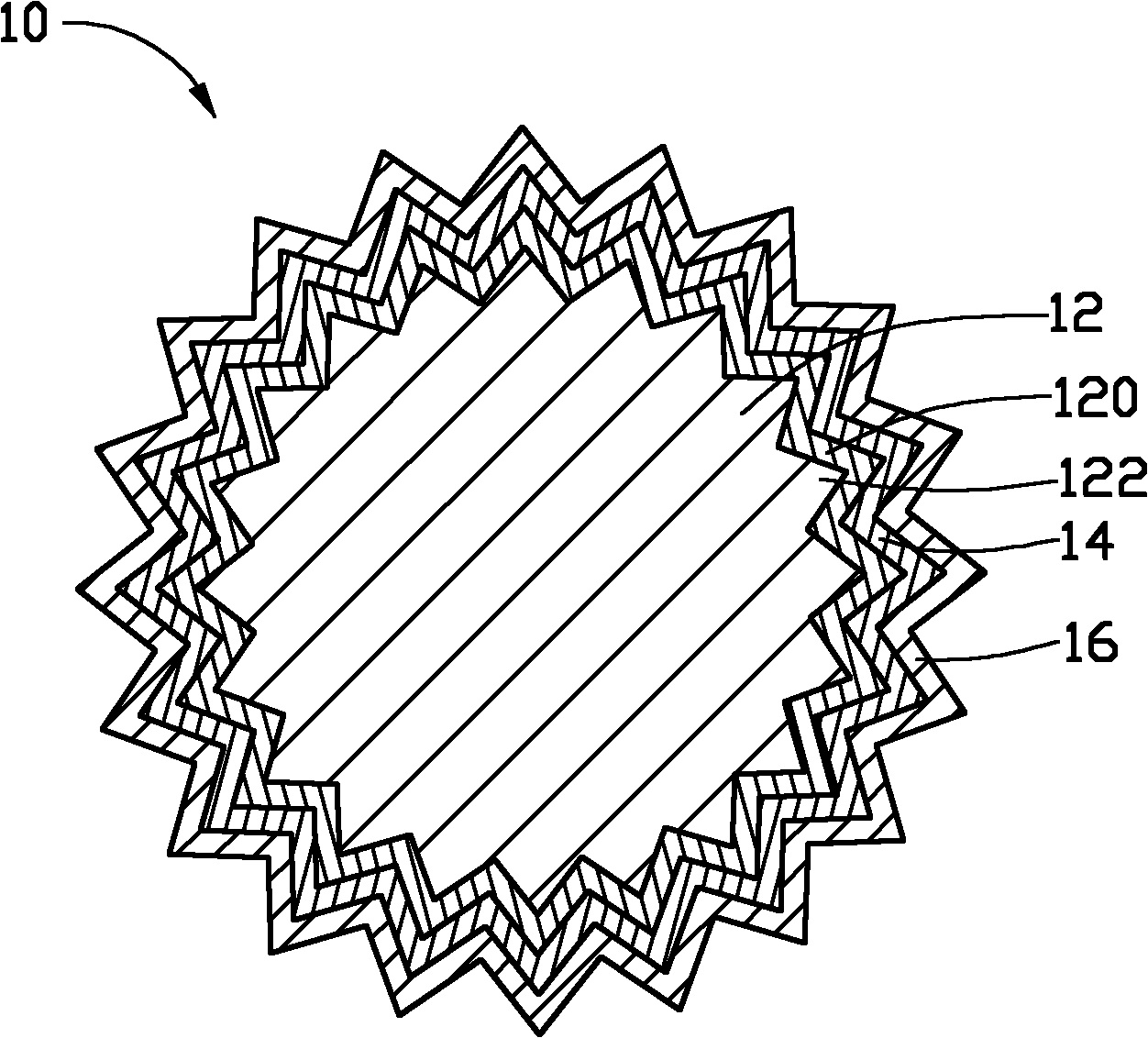

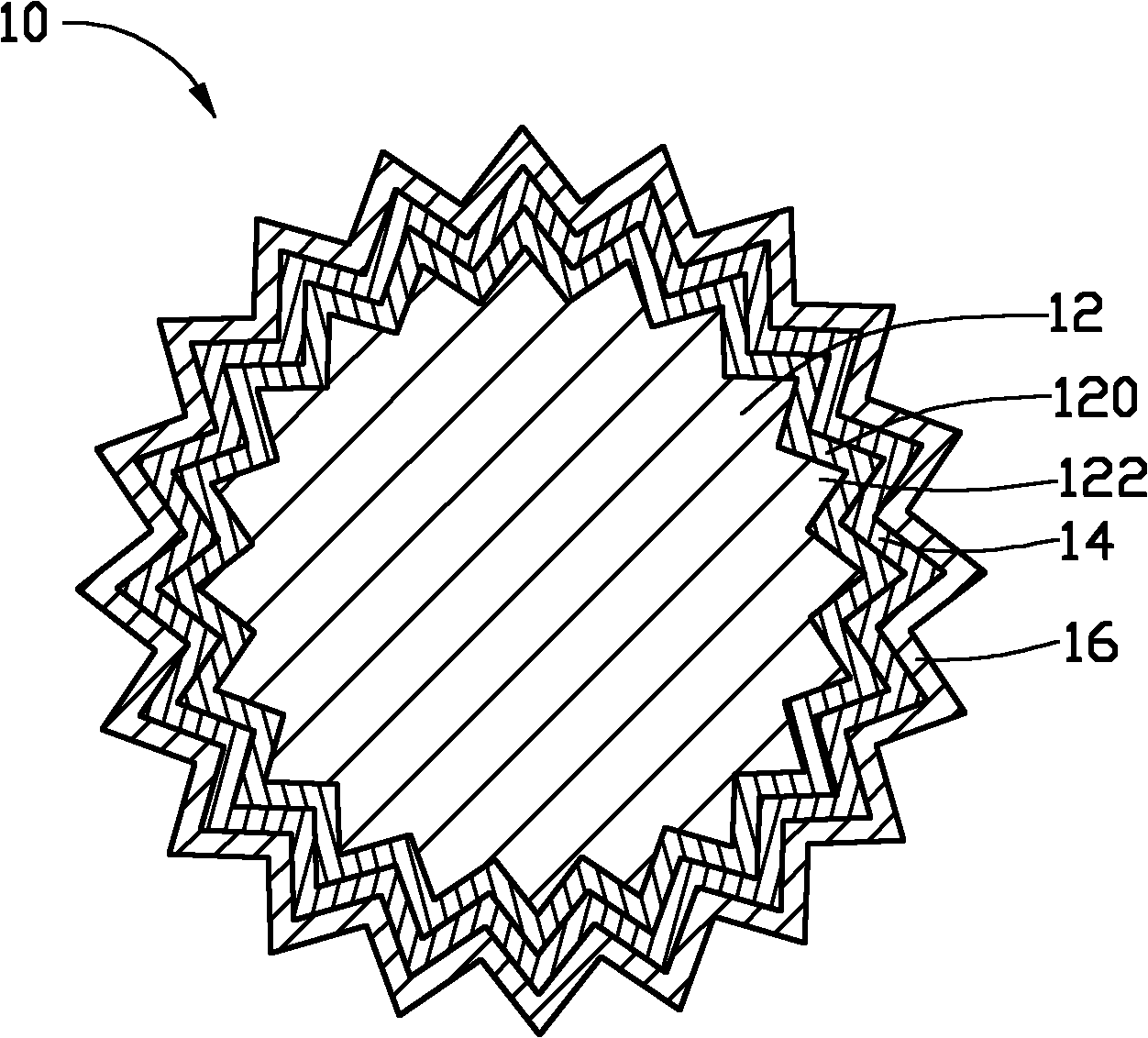

Structure and applications of high tensile strength and fast curing adhesive for metal surface

PendingCN109837032AReduce adhesionHigh tensile strengthFilm/foil adhesivesMacromolecular adhesive additivesEpoxyFiber

The invention relates to a preparation method of a high tensile strength and fast curing adhesive, wherein the adhesive has a sandwich structure comprising an organic bottom layer, a fiber reinforcinglayer and an organic surface layer, the organic bottom layer and the organic surface layer respectively comprise an epoxy resin, a curing agent polyamide and a toughening agent liquid-state rubber, and the fiber reinforcing layer comprises glass fibers impregnated with a fiber impregnating glue. According to the present invention, the adhesive has characteristics of simple formula, easily available raw materials and simple production, can be used for the adhesion between metal contact surfaces and inorganic material contact surfaces, further has advantages of excellent flowability and fast curing, has high mechanical strength, strong structure toughness, excellent corrosion resistance and excellent water resistance after being cured, and has significant adhesion effects in the fields of aerospace, shipbuilding, bridge reinforcement and the like..

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

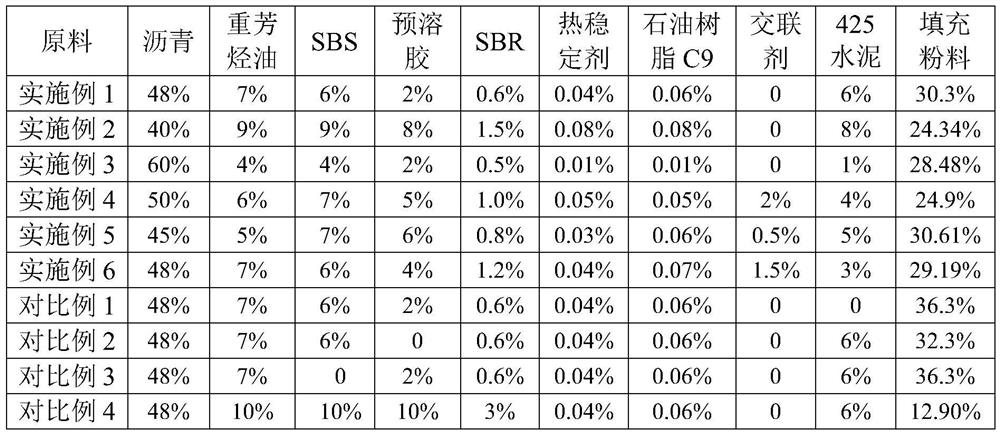

Sizing material with curing agent for improving stripping performance of S-CLF coiled material

ActiveCN112680184AImprove bindingImprove adhesionNon-macromolecular adhesive additivesBituminous material adhesivesPetroleum resinComponents of crude oil

The invention discloses a sizing material with a curing agent for improving the stripping performance of an S-CLF coiled material. The sizing material is prepared from the following raw materials in percentage by weight: 40-60% of asphalt, 4-9% of modified oil, 4-9% of SBS, 2-8% of pre-sol, 0.5-1.5% of SBR, 0.01-0.08% of a heat stabilizer, 0.01-0.08% of modified petroleum resin, 1-8% of the curing agent and the balance of filling powder. According to the sizing material , numerous raw materials are selected and compounded, and particularly, the curing agent is properly used, so that the stripping performance of the S-CLF coiled material and post-poured concrete is good, and the parameter requirements in the enterprise standard Q / 320584 PAI011-2019 are met. According to the invention, the formula of the sizing material is optimized, the viscosity of the sizing material is reduced and the performance of the sizing material is improved through component selection and content proportioning, excellent stripping performance is achieved through combination and compounding of the components, and the problem that the stripping strength of the SCLF sizing material coiled material and post-cast concrete has defects is solved. Meanwhile, other properties are ensured to meet the standard requirements.

Owner:SHENZHEN ZHUOBAO TECH +1

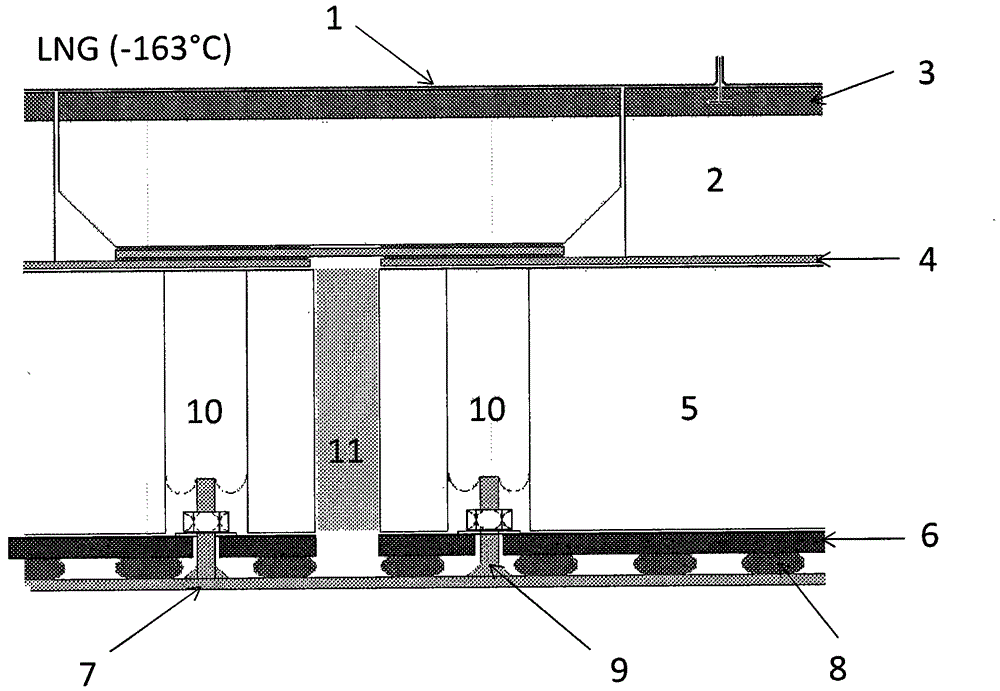

Use of an adhesive composition based on silylated polymers for cryogenic applications

ActiveCN104804696ACompensate for surface irregularitiesAvoid damageNon-macromolecular adhesive additivesGas handling applicationsSilylationFuselage

The present invention relates to the use of an adhesive composition comprising at least one silylated polymer and at least one filler for the assembly of a tank comprising a fluid at a temperature less than or equal to -100 DEG C and a structure carrier selected from the hull of a ship, the cabin of an aircraft and a container.

Owner:BOSTIK SA

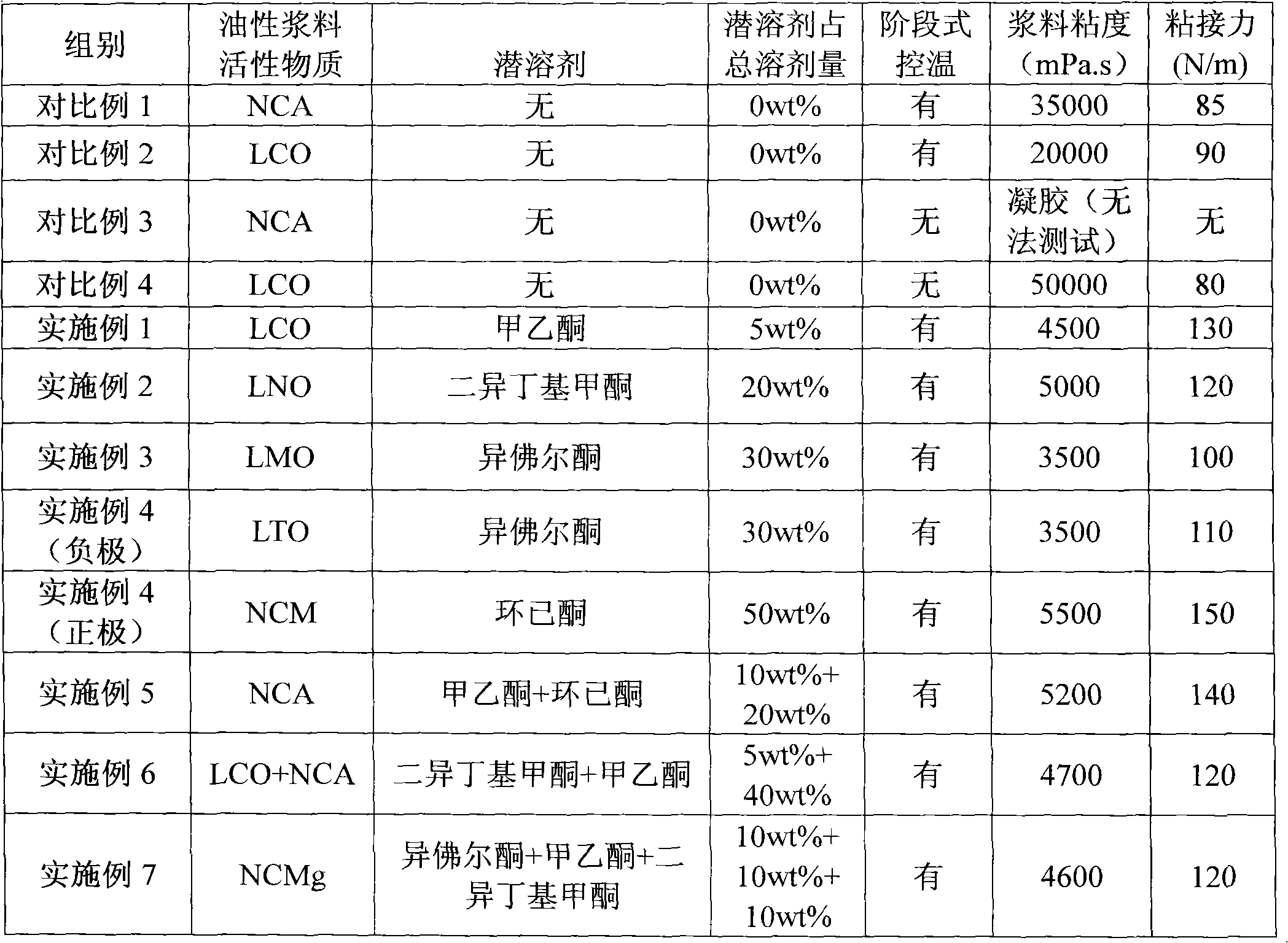

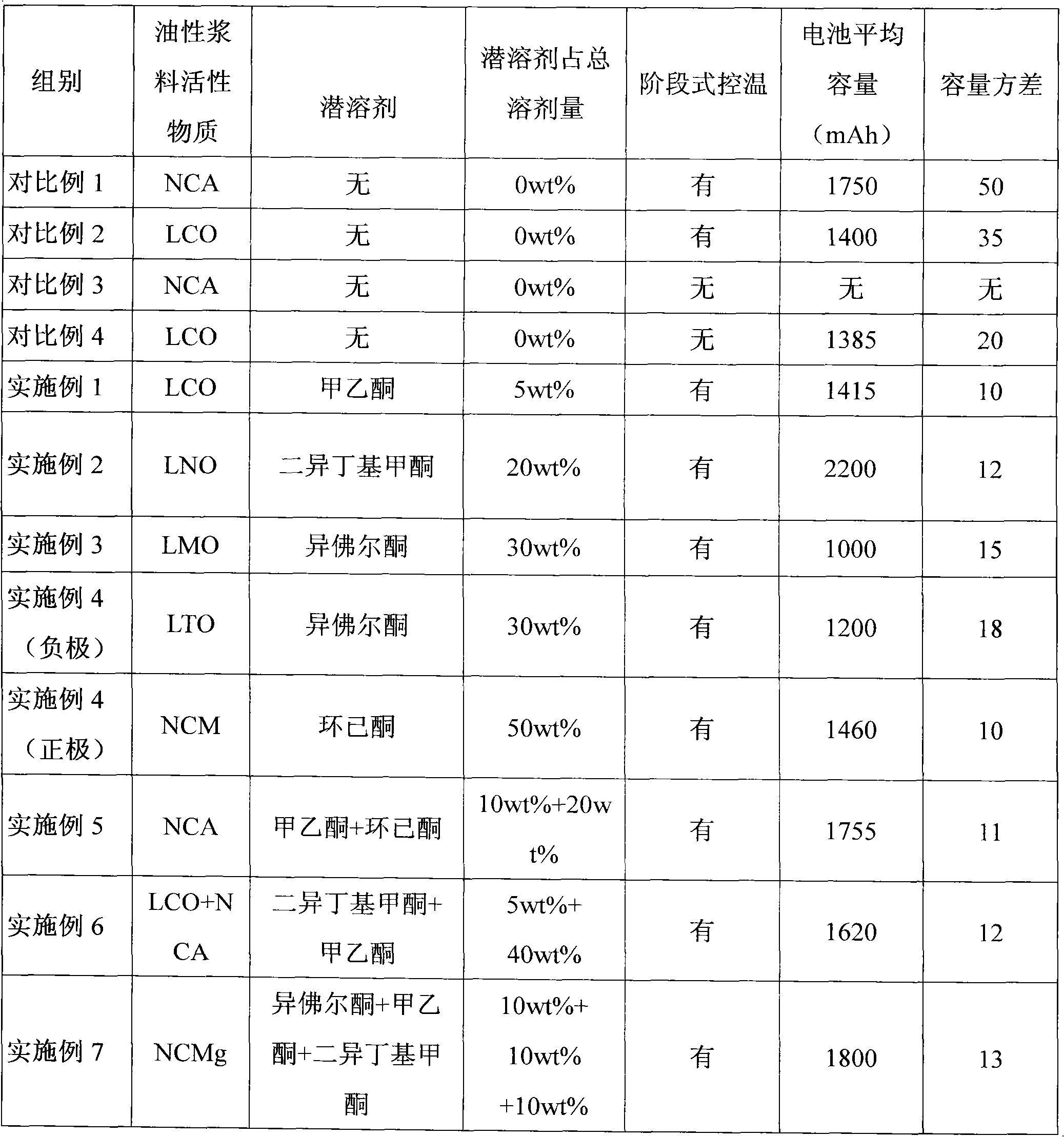

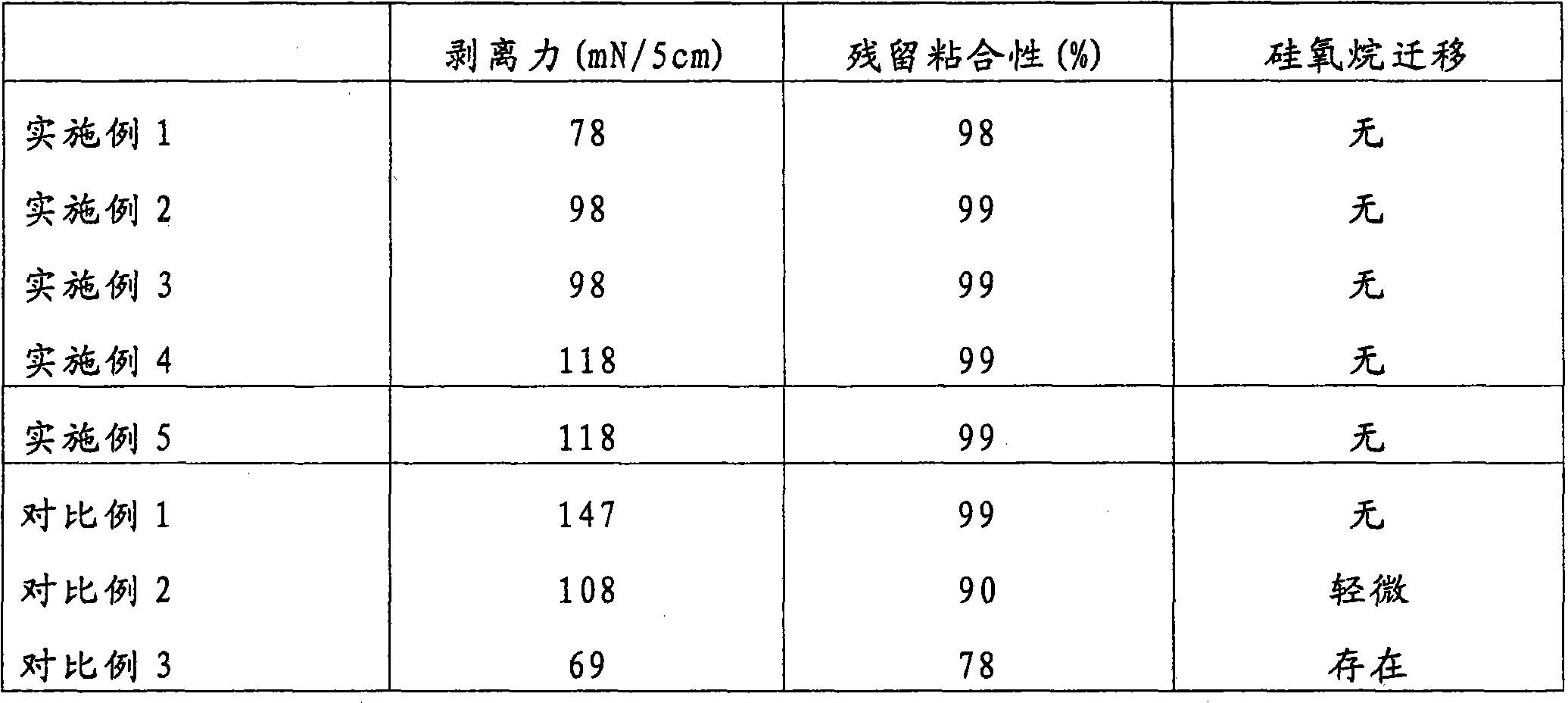

Process for preparing oil slurry of lithium ion battery

The invention belongs to the technical field of lithium ion batteries and in particular relates to a process for preparing the oil slurry of a lithium ion battery. The process comprises the following steps of: 1, adding an organic true solvent and an adhesive into a stirring tank, stirring at the temperature of 45 to 55 DEG C to completely dissolve the adhesive, and thus obtaining an adhesive solution; 2, adding a conductive additive into the adhesive solution which is obtained in the step 1, stirring at the temperature of 45 to 55 DEG C, and then cooling to 20 to 35 DEG C; 3, adding a latent solvent into a solution which is cooled in the step 2, and stirring at the temperature of 20 to 35 DEG C; and 4, adding an active material into the solution which is obtained in the step 3, stirring at the temperature of 20 to 35 DEG C, and thus obtaining the oil slurry. Compared with the prior art, the process for preparing the oil slurry of the lithium ion battery has the advantages that by adding the latent solvent in the slurry preparation process and controlling stirring temperature by stages, gelling of the slurry can be prevented, the stability and consistency of the slurry can be improved, a pole piece with high adhesion force can be obtained, and the lithium ion battery which is prepared by using the pole piece is high in capacity consistency.

Owner:DONGGUAN AMPEREX TECH

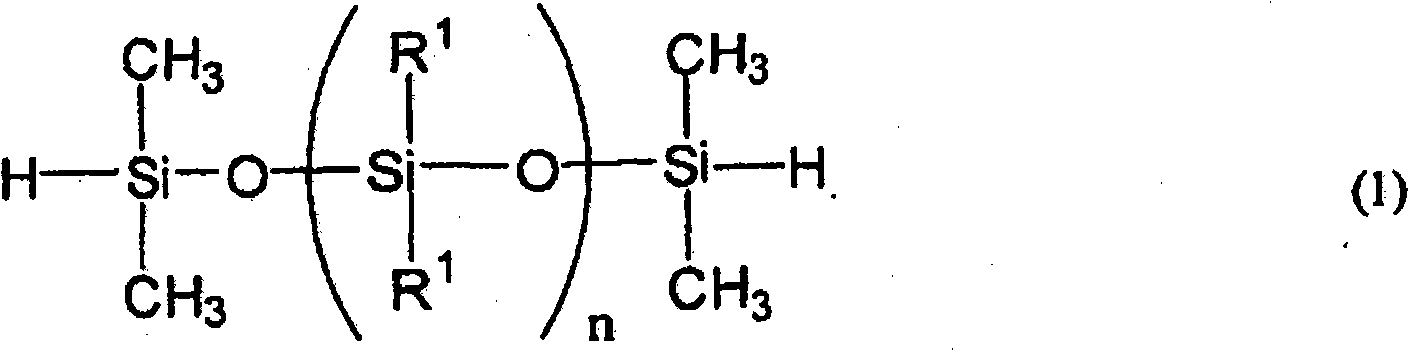

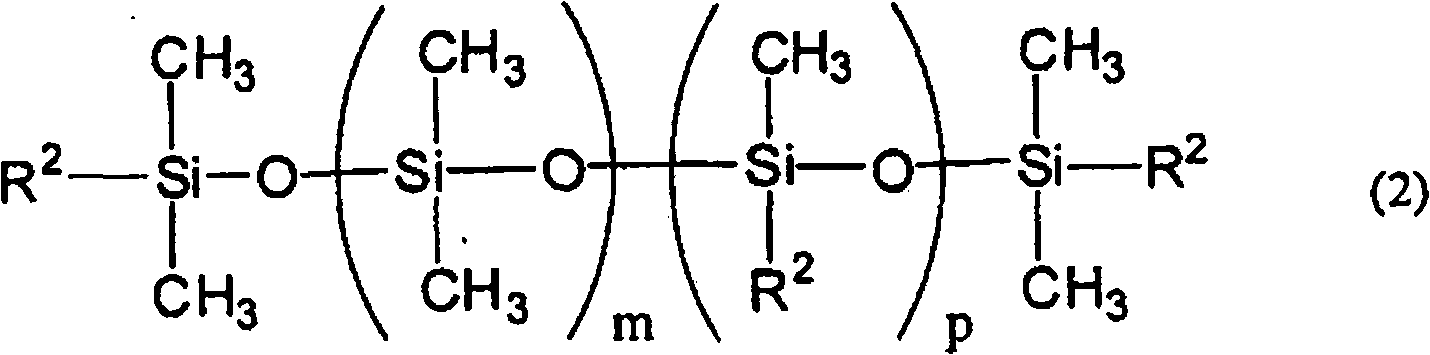

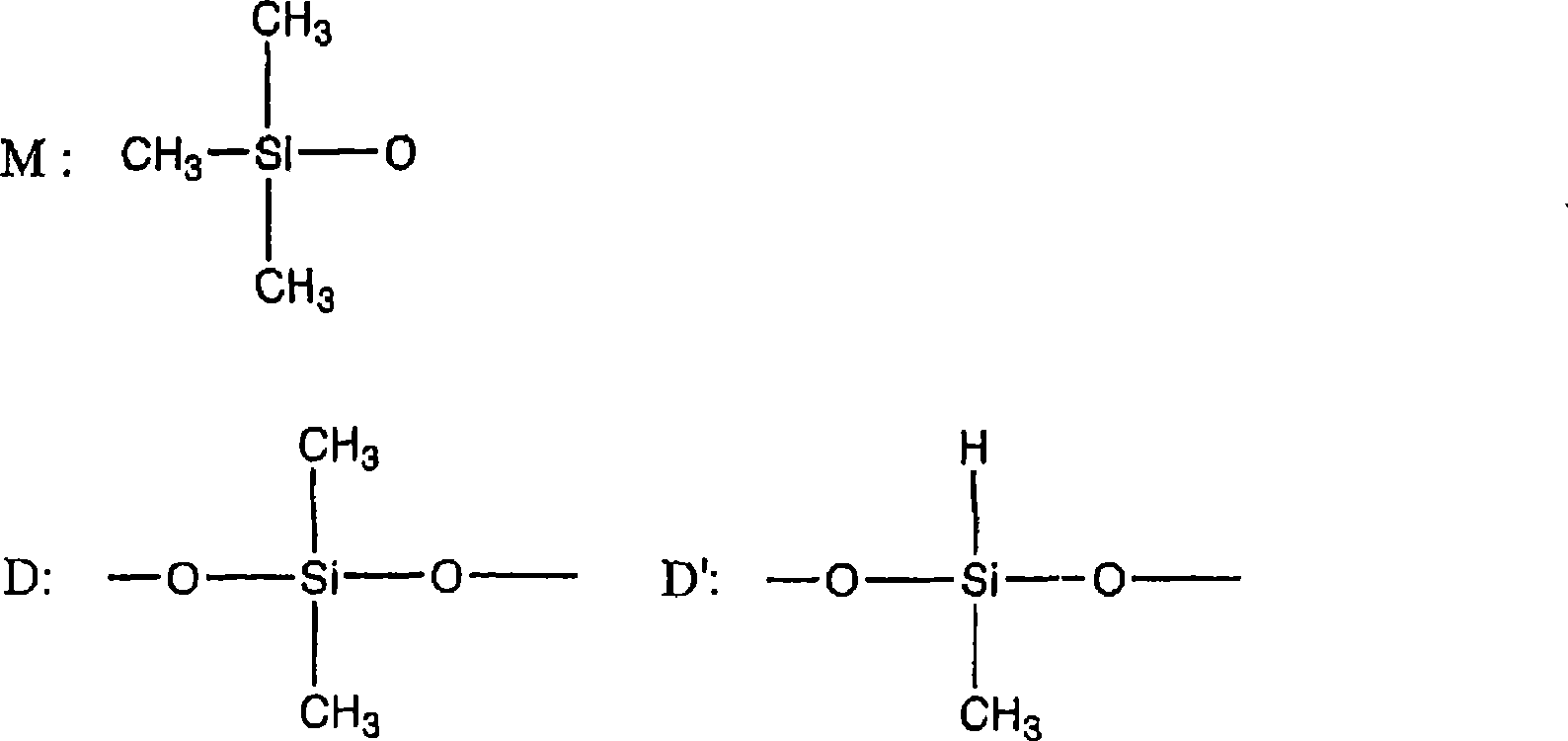

Solvent-based release coating-forming organopolysiloxane composition and release film or sheet

InactiveCN101848972AExcellent peelabilityPromote migrationCoatingsFilm/foil adhesive release linersPlatinumOrganic solvent

To provide a solvent-based release coating-forming organopolysiloxane composition exhibiting excellent release properties. The organopolysiloxane composition comprising (A) organopolysiloxane having two alkenyl groups, (B) organohydrogenpolysiloxane having at least three silicon-bonded hydrogen atoms bonded in side-chain position on the molecular chain, (C) straight-chain organohydrogenpolysiloxane having a viscosity at 25 DEG C of 2.5 to 2,000 mPas and silicon-bonded hydrogen at both molecular chain terminals, (D) a platinum-type catalyst, and (E) organic solvent and optionally (F) a photopolymerization initiator.

Owner:DOW CORNING TORAY CO LTD

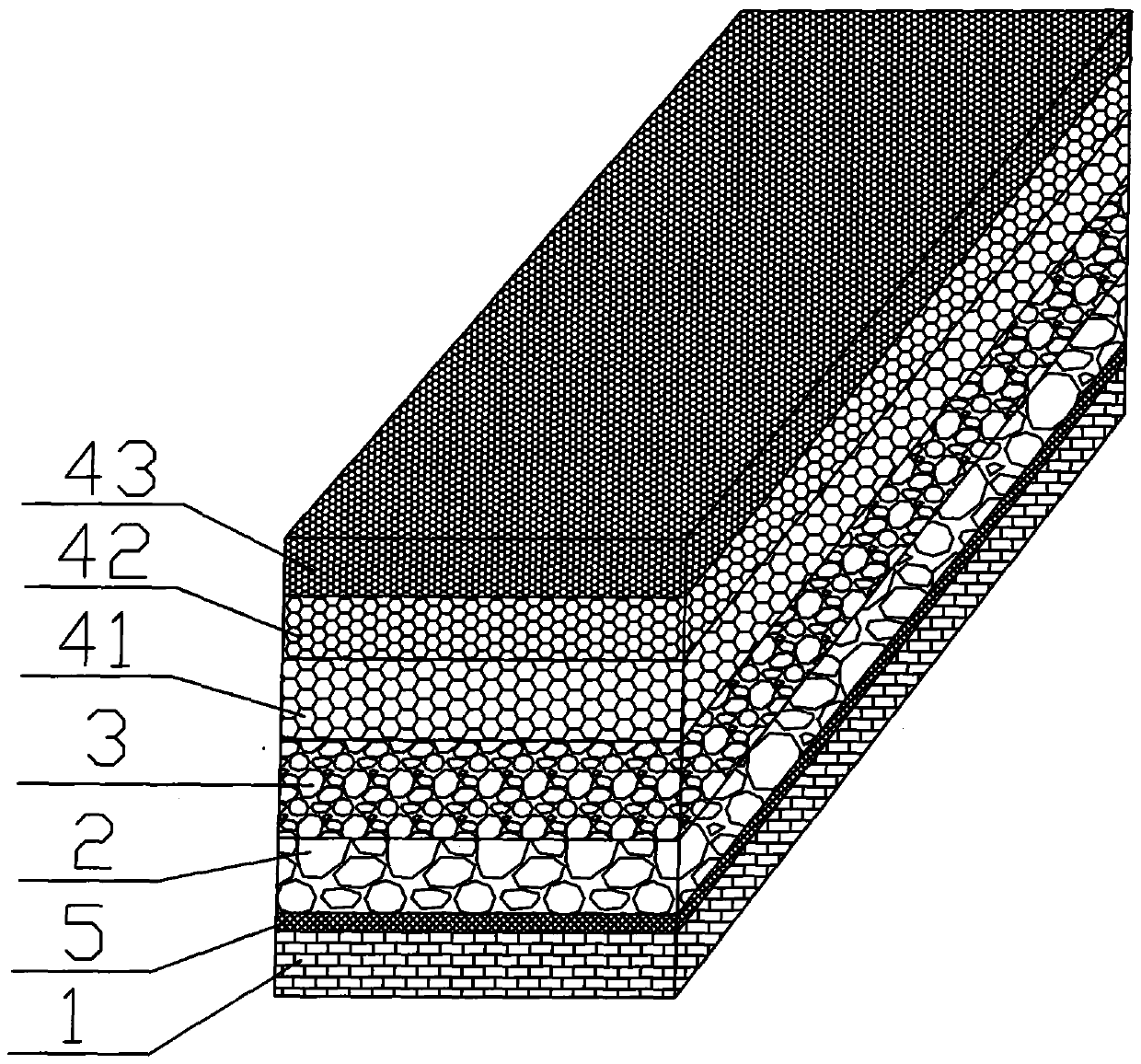

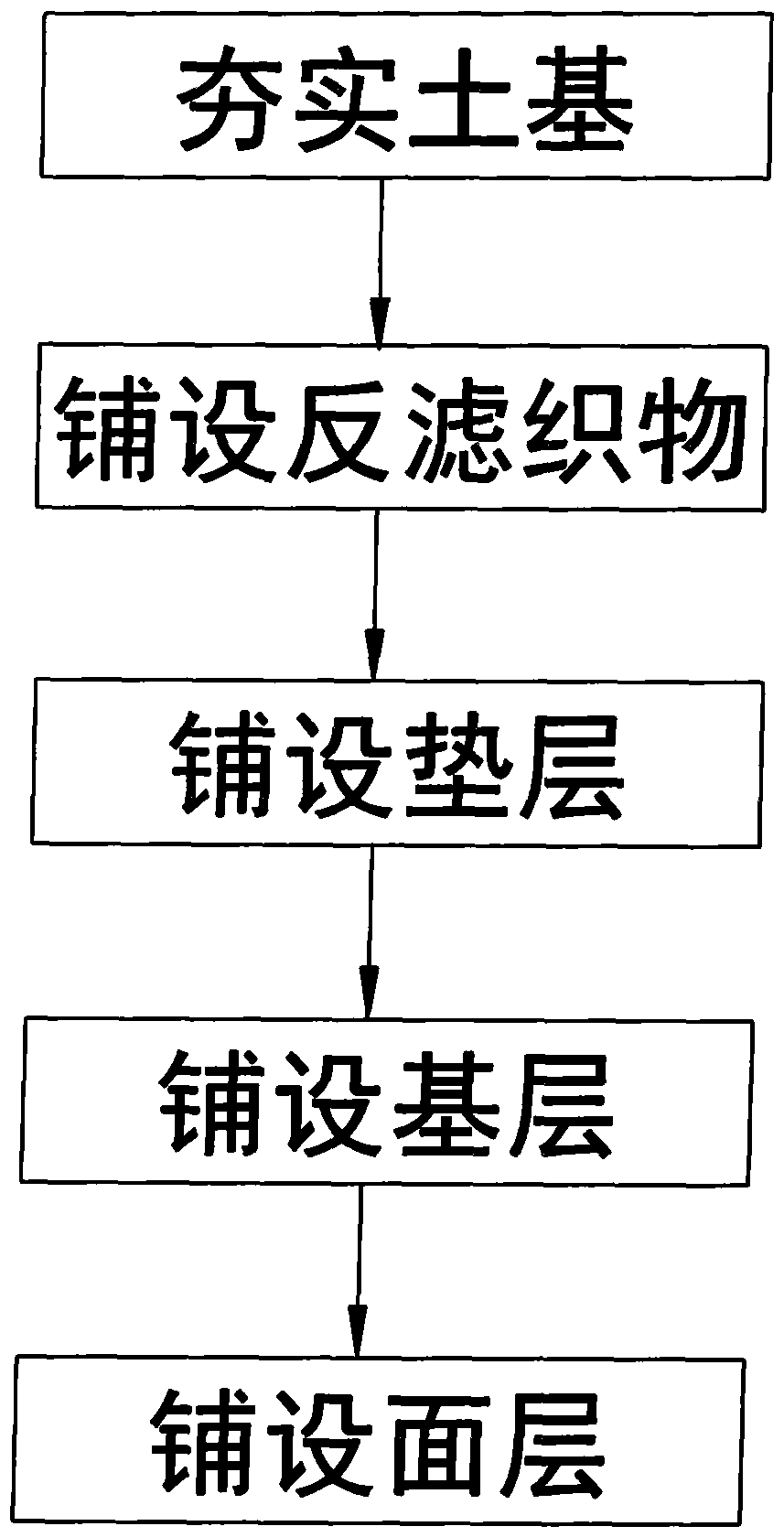

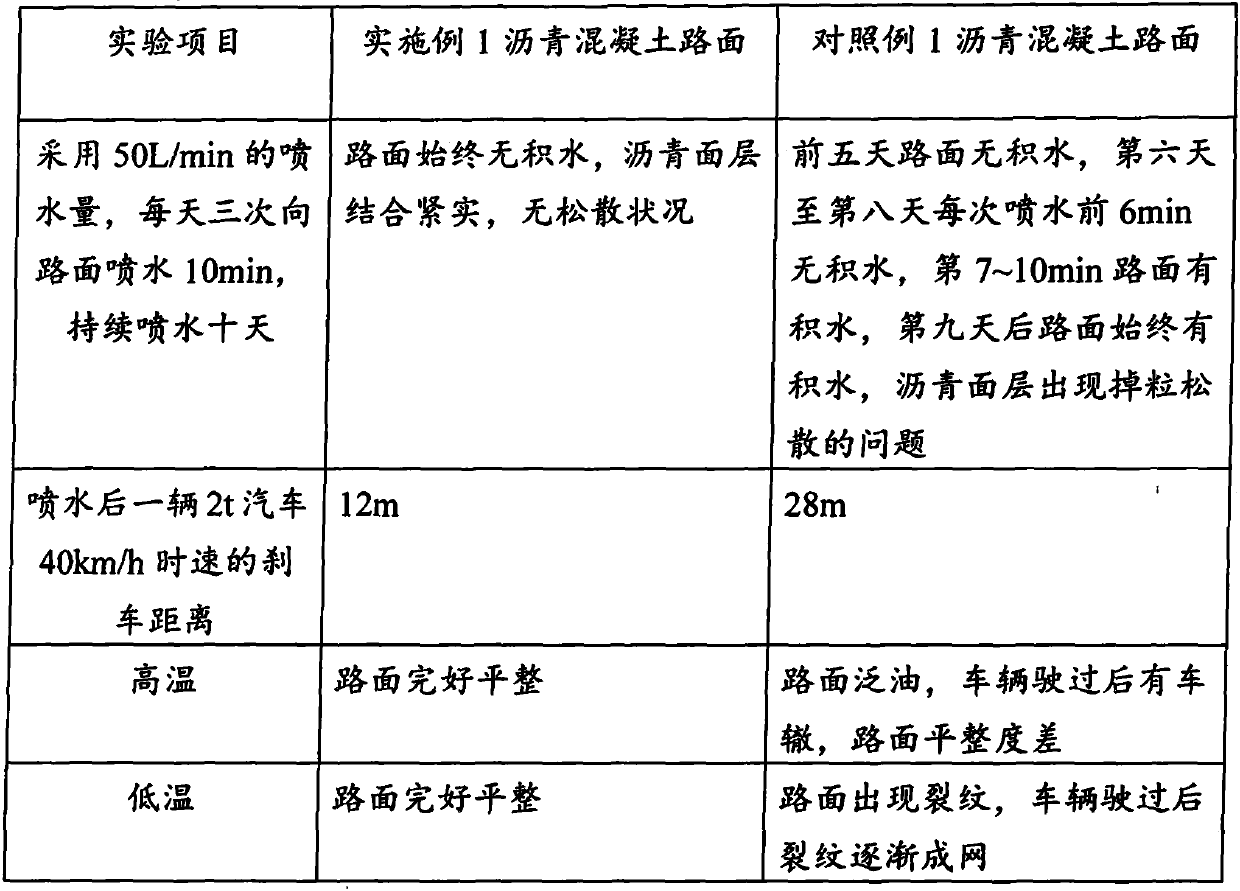

Asphalt concrete pavement structure and laying technology thereof

The invention provides an asphalt concrete pavement structure and a laying technology thereof. The laying technology comprises the steps that one of crushed building concrete slag, broken stone and gravel is used as a bedding layer, a mixture of broken stone and slag or a mixture of coal cinder and slag or a mixture of broken stone, coal cinder and slag is used as a base layer, the bedding layer and the base layer can make rainwater quickly infiltrated and discharged, the water storage capacity of the bedding layer and the base layer is high, under stress, water cannot go upwards and cannot corrode asphalt concrete, and an asphalt pavement is prevented from being damaged by the water; by using the ATPB asphalt mixture, the AM asphalt mixture and the OGFC asphalt mixture as a surface layer,the rainwater can quickly infiltrate, the adhesion force of asphalt cannot be reduced, the cohesive force between asphalt and mineral aggregates in the asphalt pavement cannot be destroyed, it is ensured that the stress on the whole road structure is uniform, when the road structure is under force at the extreme temperature, the road structure is not prone to deformation, the service life is long, and the temperature stability is high.

Owner:XINJIANG BEIXIN ROAD & BRIDGE GRP +1

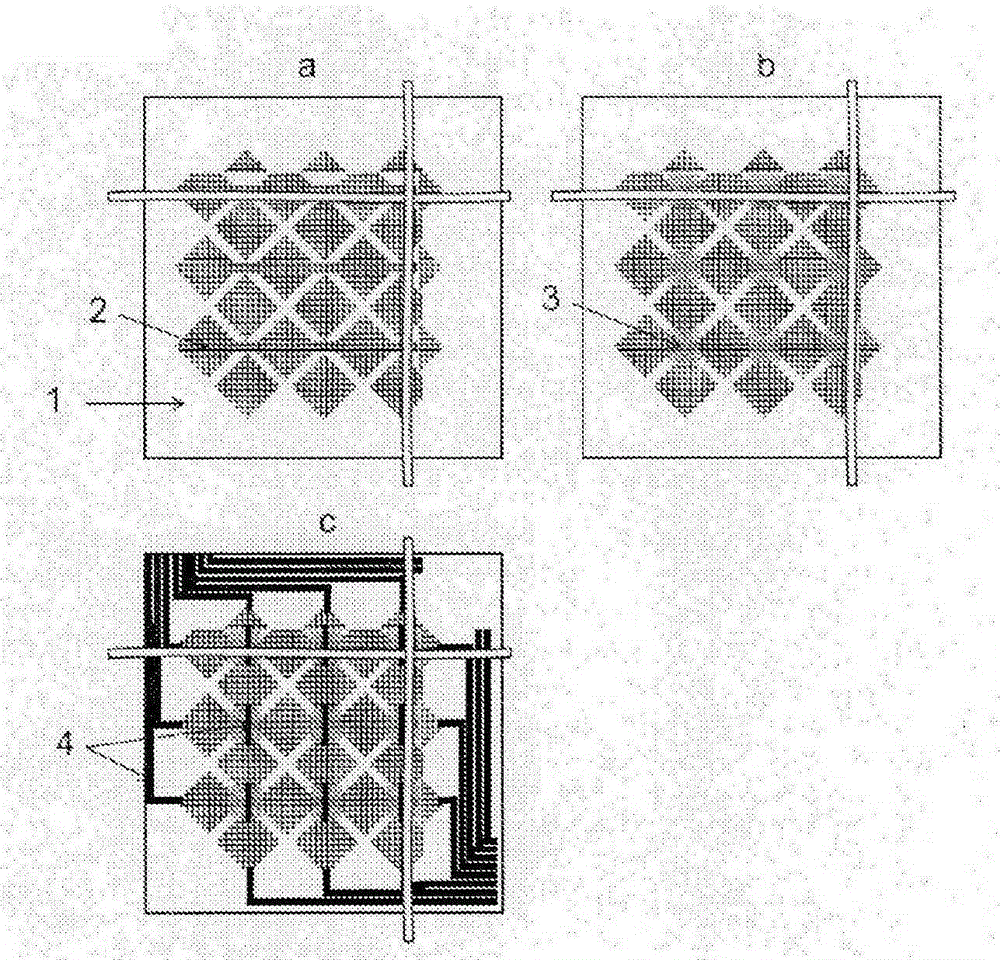

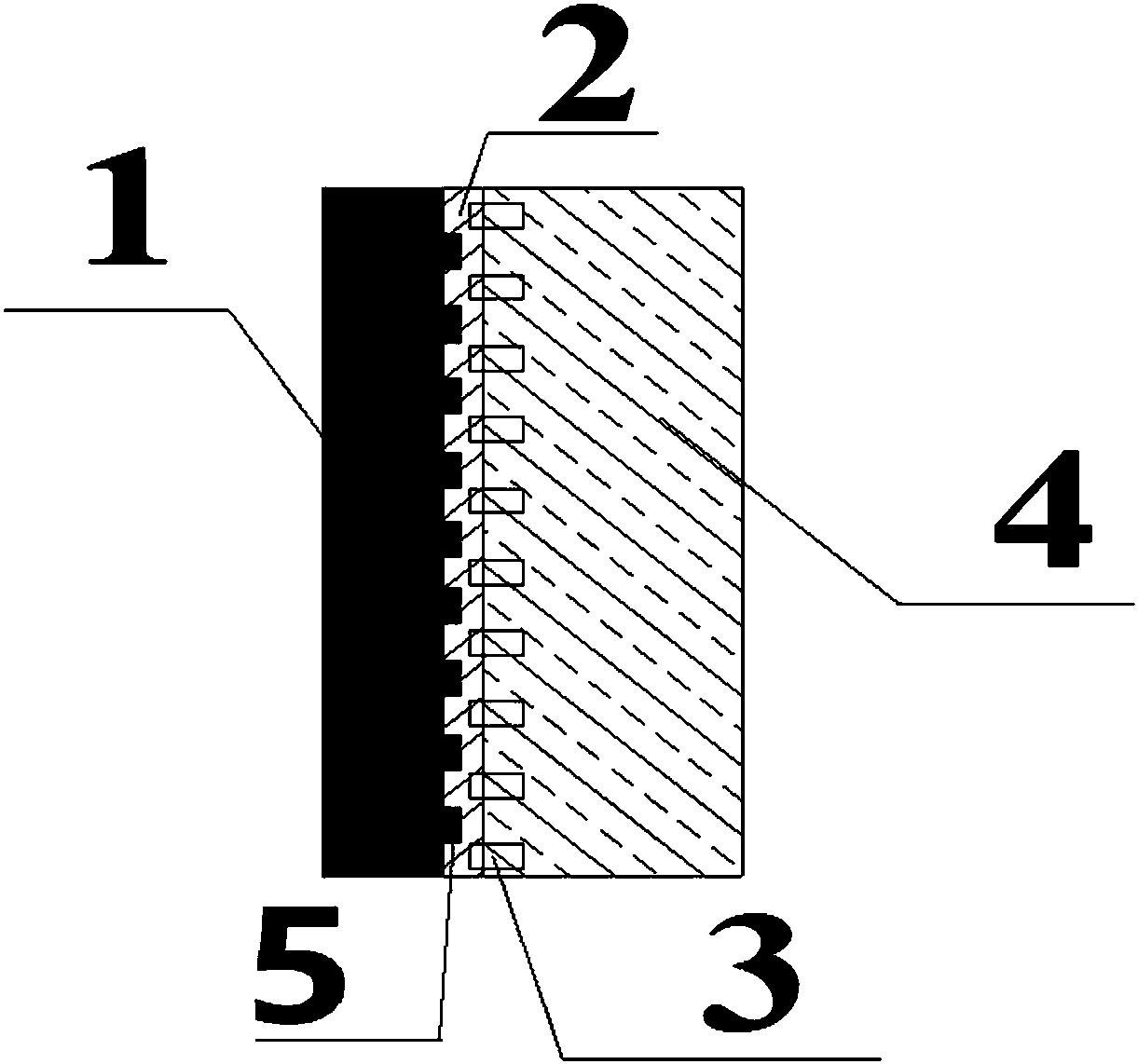

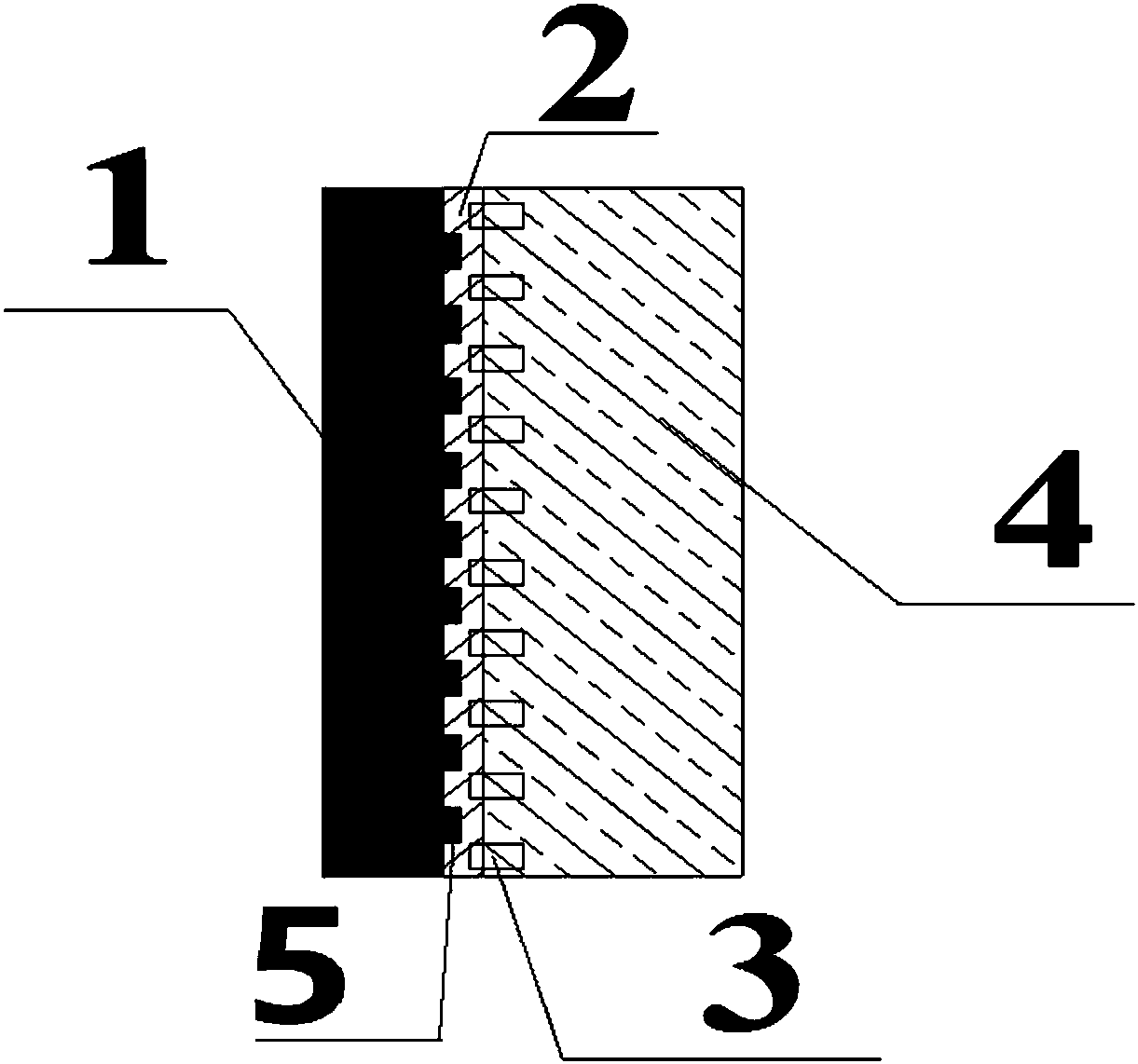

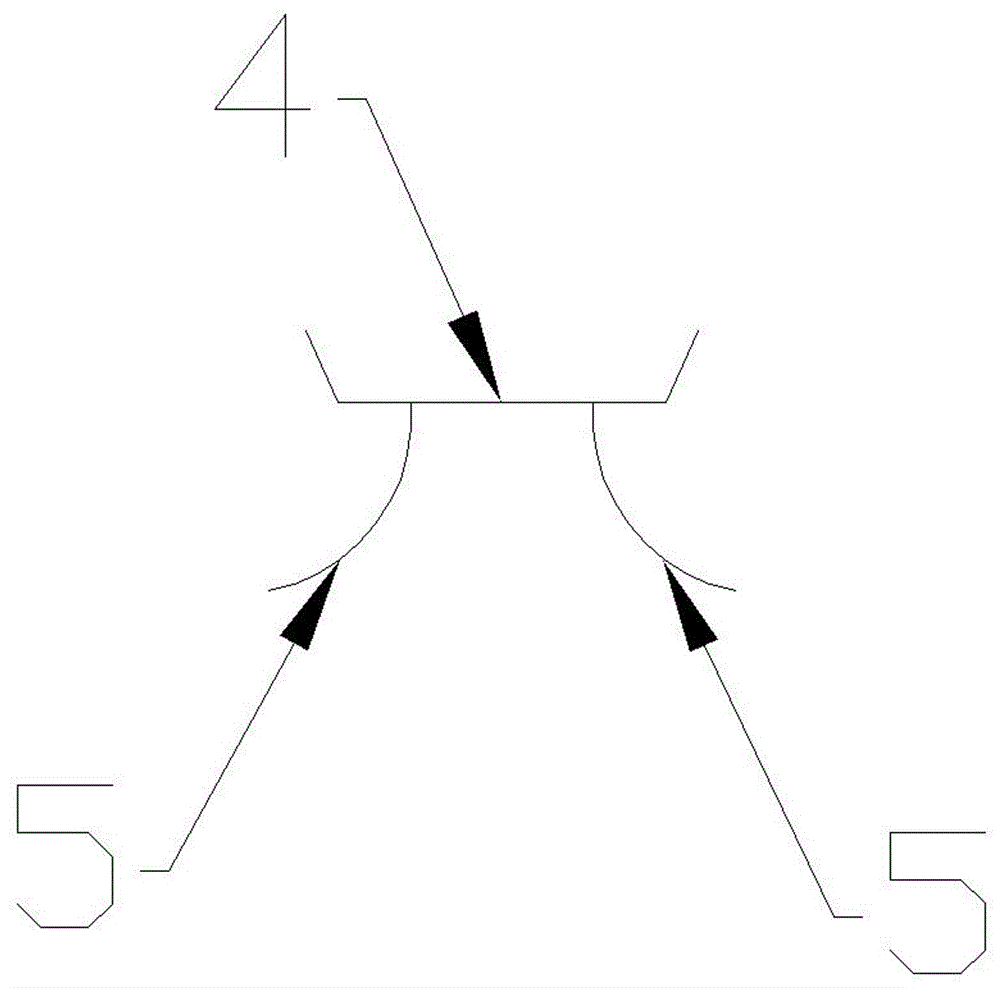

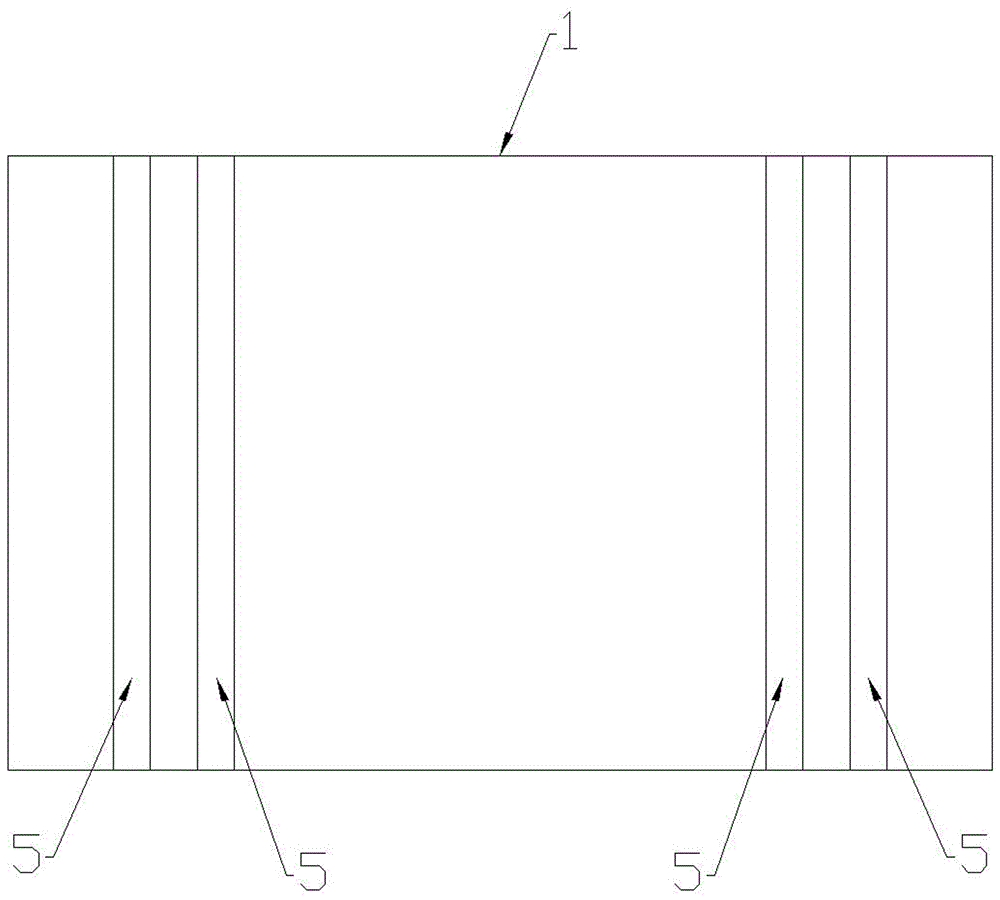

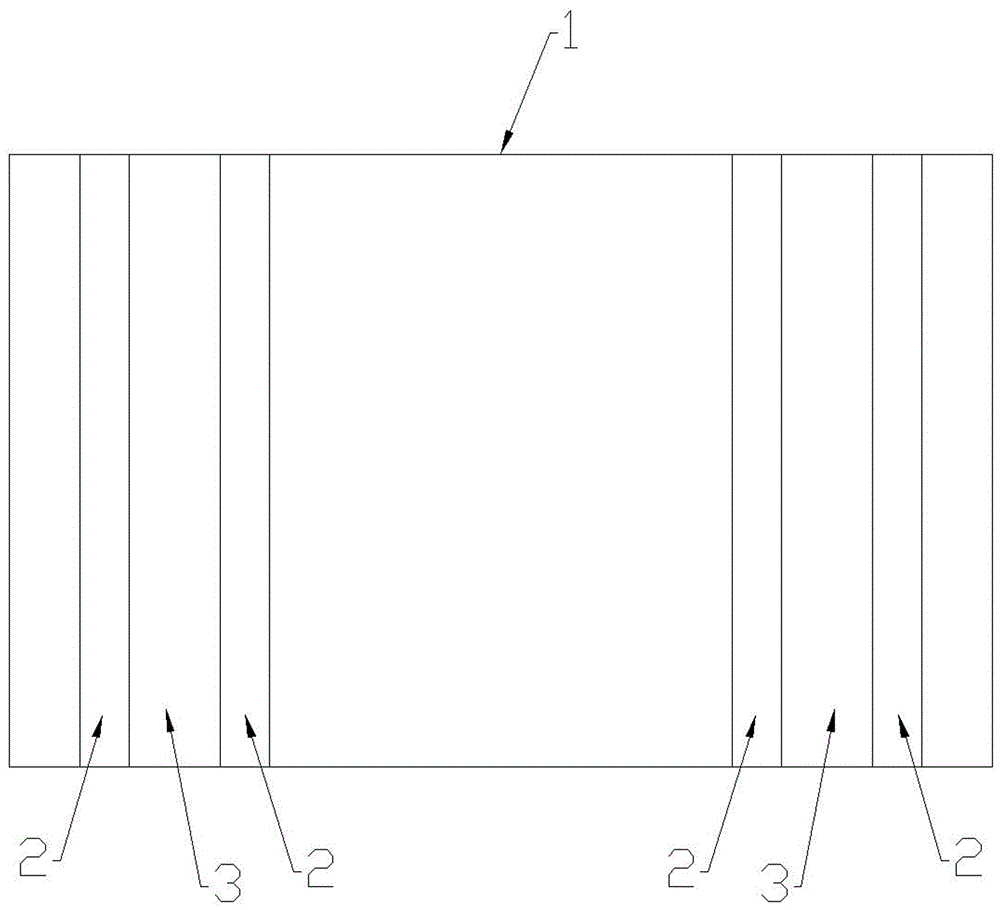

Wall surface tile incapable of falling off

InactiveCN106437074AWon't fall offHigh strengthCovering/liningsAdhesion forceUltimate tensile strength

The invention relates to a wall surface tile incapable of falling off and is mainly used in the field of construction engineering decoration. The wall surface tile has the benefits that the strength of the tile cannot be reduced, and the adhesion force of the tile onto cement mortar is strong, so that the tile cannot to fall off. The wall surface tile provided by the invention mainly consists of a tile 1, projecting parts 2, an inverted trapezoidal groove 3, a clamping steel sheet 4 and anchoring legs 5. The wall surface tile adopts a main working principle that the thickness of an original tile is kept unchanged, the plurality of projecting parts 2 are additionally arranged, and the clamping steel sheet 4 is inserted in the inverted trapezoidal groove 3 between the two projecting parts 2; when the tile is adhered, only adhering motor is required to be scraped onto the back surface of the tile, each space of each of the anchoring legs 5 is filled with the adhering motor, and then the tile is adhered onto original cement mortar on a wall surface; antirust coatings are formed on the clamping steel sheet 4 and the anchoring legs 5; as the appearance of each of the circular arc-shaped anchoring legs 5 is simple and smooth, the adhering mortar easily enters all corners of the anchoring leg 5; after the adhering mortar reaches the strength, the anchoring requirements are fully met, so that the tile cannot fall off.

Owner:JINGMEN CHUANGJIA MACHINERY TECH CO LTD

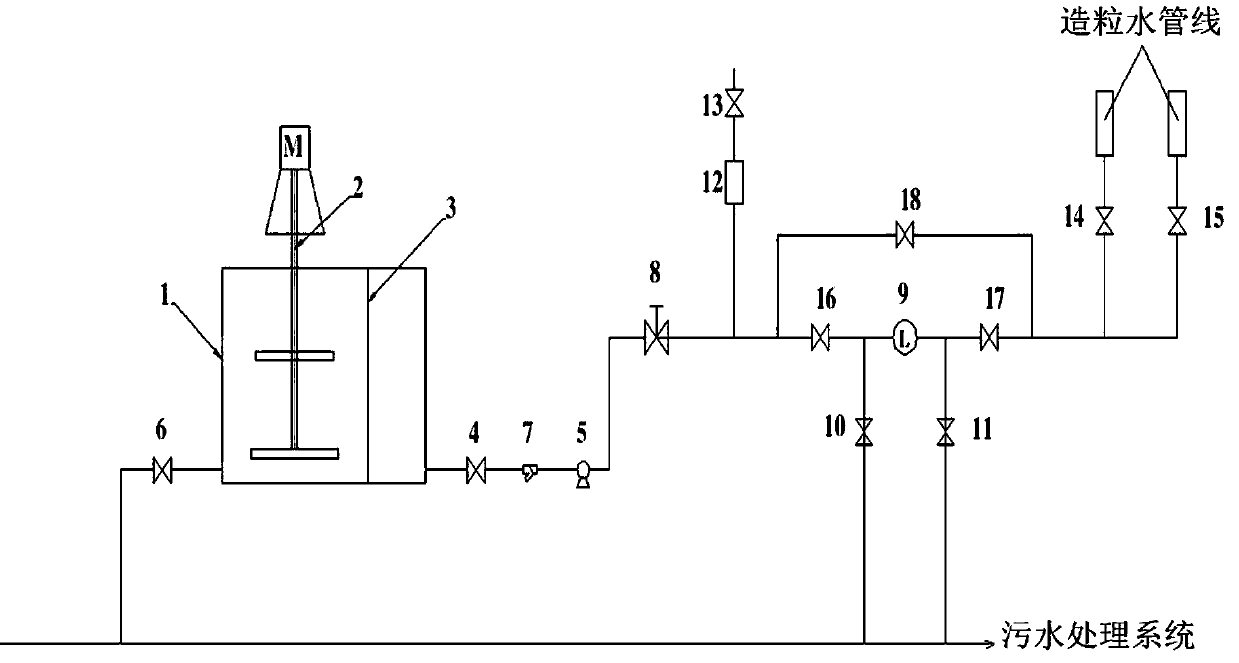

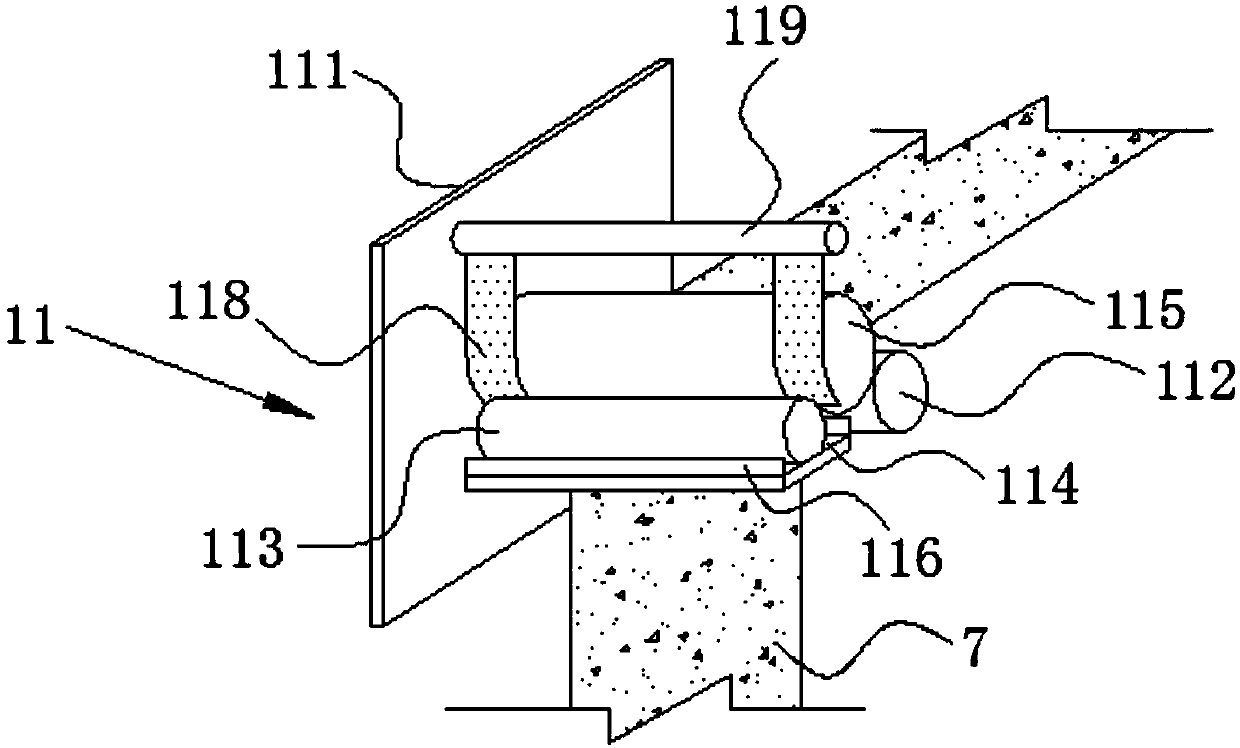

Carbon black pH value adjustment apparatus and method

ActiveCN110862701AWell mixedChange surface acidityPigmenting treatmentChemical industryProcess engineeringEnvironmental engineering

The invention provides carbon black pH value adjustment apparatus and method. The carbon black pH value adjustment apparatus comprises an alkaline solution preparation tank; the interior of the alkaline solution preparation tank is divided into a first chamber and a second chamber by a screen mesh; a stirrer is installed inside the first chamber; the bottom of the second chamber communicates withan input end of a plunger pump through a tube; a filter is installed inside the tube; a pressure regulating valve is installed at an output end of the plunger pump; a flow meter is installed on an output pipe of the pressure regulating valve; sluice valves are respectively installed on an input pipe and an output pipe of the flow meter; the sluice valves installed on the output pipe of the flow meter synchronously communicates with two pipelines which are respectively installed with sluice valves; and the two pipelines communicate with a granulating water pipe. Through communication with the granulating water pipe, the carbon black pH value adjustment apparatus is capable of uniformly mixing an alkaline solution with granulating water; the alkaline solution is introduced before entering ofthe granulating water and a binder into a granulation machine, so that surface acidity and basicity of carbon black are changed; and acidity of the binder is neutralized by an alkali adding device without reduction of adhesive property, so that pH value of the carbon black is effectively increased. Therefore, quality stability of carbon black products can be effectively guaranteed so as to meet customer needs.

Owner:嘉峪关大友嘉能精碳科技股份有限公司

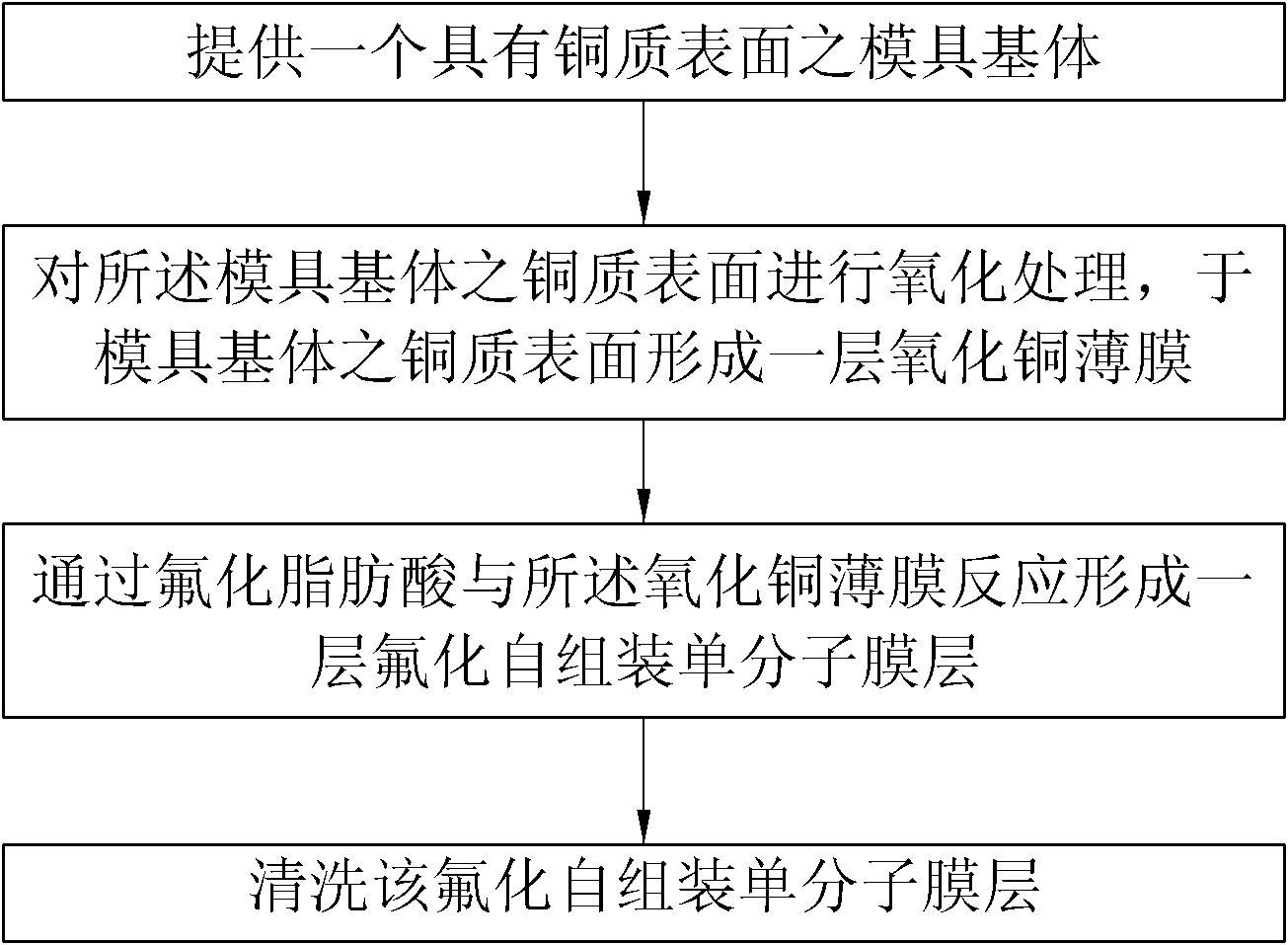

Optical film processing die and manufacturing method thereof

InactiveCN102433561AExtend your lifeEfficient releaseSuperimposed coating processThin membraneMembrane surface

The invention discloses an optical film processing die, which comprises a die substrate, a copper oxide film and a film layer, wherein the die substrate is provided with a copper surface; the copper oxide film is formed on the copper surface; and the film layer is formed on the surface of the copper oxide film, and is a fluorinated self-assembly monomolecular film layer with high hydrophobicity. The die disclosed by the invention has the characteristic of easiness in demolding. The invention further provides a manufacturing method of the optical film processing die.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Wear-resistant concrete

The invention discloses wear-resistant concrete. The wear-resistant concrete is prepared from, by weight, 100 parts of modified epoxide resin, 6-8 parts of ethidene diamine, 15-20 parts of isobutanol, 8-10 parts of dibutyl phthalate, 250-300 parts of ceramsite, 200-250 parts of gravel, 1-2 parts of fluororubber, 0.5-0.7 part of polyurethane fiber and 150-170 parts of cement. The wear-resistant concrete is good in corrosion resistance, high in corrosion resistance and good in mechanical strength.

Owner:蚌埠市方阵商品混凝土有限公司

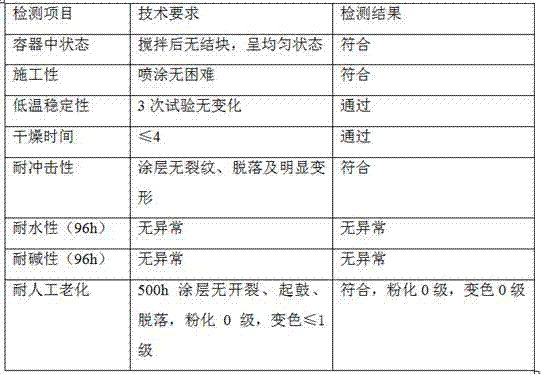

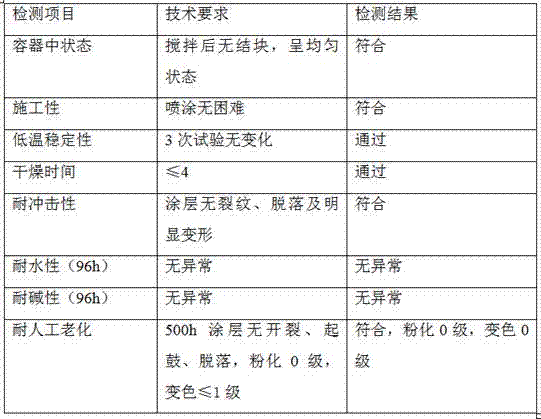

Super-hydrophobic colored real stone paint coating and preparation method thereof

The invention discloses a super-hydrophobic colored real stone paint coating and a preparation method thereof. The super-hydrophobic colored real stone paint coating disclosed by the invention comprises the following components in parts by weight: 30-60 parts of a color matching sand-containing basic paint, 20-35 parts of protective colloid and 20-35 parts of a continuous phase. The coating disclosed by the invention is excellent in hydrophobicity, rain cannot be retained on the surface of a coating layer, the retention time of moisture on the surface of the coating layer is shortened, long-term contact of the coating layer with water is avoided, the pollution resistance of the coating layer is improved, and the service life of the coating layer is greatly prolonged; due to environmental-friendly aqueous raw materials, the coating is good in adhesion property to various substrates, excellent in color contrast property and very good in stereoscopic sensation; the coating layer is rich and diverse in effect and simple and convenient to construct, and can be customized according to design requirements.

Owner:福建华夏蓝新材料科技有限公司

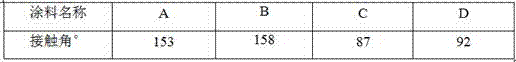

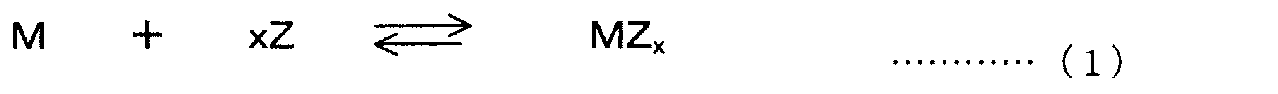

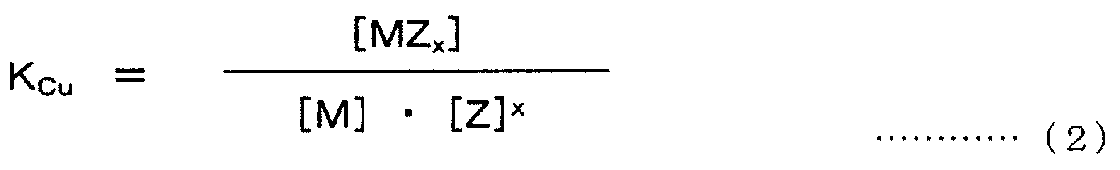

Silicone adhesive agent

InactiveCN1894785ADoes not reduce zygosityDoes not reduce adhesionNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsLead frameSilicone adhesive

A silicone adhesive agent for joining a semiconductor pellet and a member for mounting said pellet, which comprises a addition reaction curing type silicone rubber composition exhibiting a stain onto a glass plate during curing by heating of a contact angle on the glass of 70° or less. The silicone adhesive agent does not lower the wire bondability and also does not lower the adhesion between the surface of a semiconductor pellet or a lead frame and a scaling resin.

Owner:迈图高新材料日本控股有限责任公司

High-temperature resistant sectional curing epoxy paint and use method thereof

ActiveCN106010127ANo crackDoes not reduce adhesionFireproof paintsEpoxy resin coatingsNitrile rubberHexahydrophthalic anhydride

The invention relates to high-temperature resistant sectional curing epoxy paint and a use method thereof. The high-temperature resistant sectional curing epoxy paint comprises a component A, a component B and a component C which are mixed in a certain ratio, wherein the component A is an epoxy resin component which comprises E-20 bisphenol A epoxy resin, E-51 bisphenol A epoxy resin, F-51 phenolic epoxy resin, carboxyl terminated nitrile rubber modified tetra-glycidyl amide type epoxy resin, aluminium oxide, micron-grade and nanometer-grade aluminum nitride balls, fumed silica, a wetting dispersant and a coupling agent; the component B is a first curing agent component which comprises a YH-82 epoxy curing agent, a C-1041 cardanol epoxy resin curing agent, DMP(Dimethylphthalate)-30, fumed silica and micron-grade aluminum nitride balls; the component C is a second curing agent component which comprises hexahydrophthalic anhydride, fumed silica and micron-grade aluminum nitride balls. The high-temperature resistant sectional curing epoxy paint prepared by the invention has the effects of low temperature pre-curing for avoiding uniform paint films, and high temperature curing, thereby keeping high strength and good adhesion of the paint films formed by low temperature curing.

Owner:中国森田企业集团有限公司

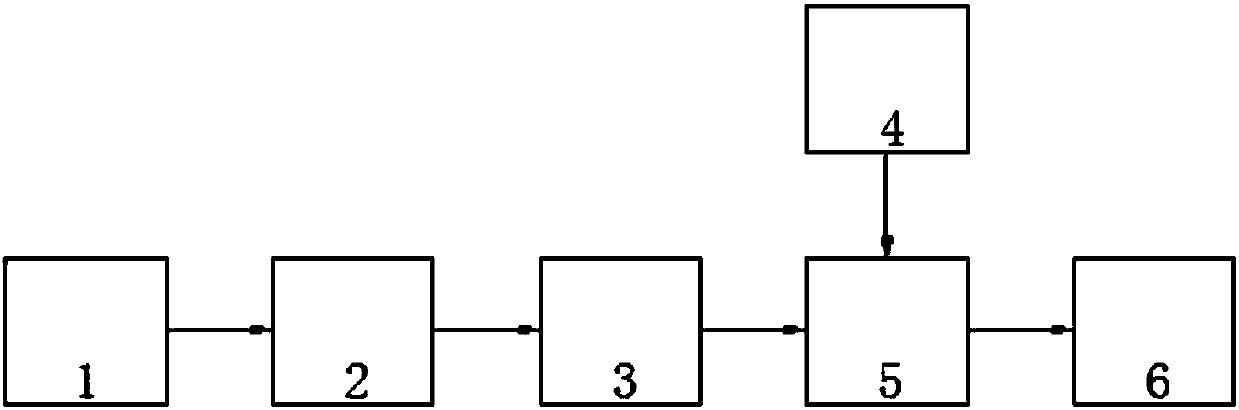

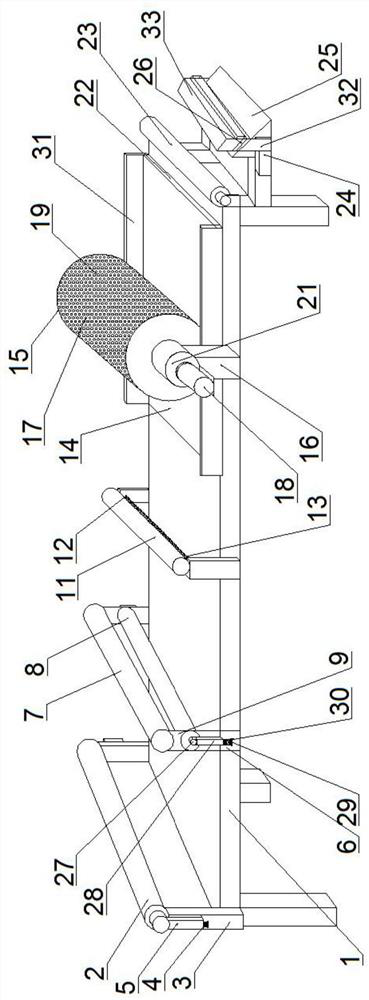

Environment-friendly handbag production line

ActiveCN108032554AHigh degree of automationQuality improvementBag making operationsPaper-makingProduction lineEngineering

The invention discloses an environment-friendly handbag production line. The environment-friendly handbag production line comprises a flexible printing device, a tailoring device, a bag body cylinder-forming device, a handlebar machine, a gluing forming device and a press. According to the manufacturing process of a handbag, the flexible printing device is located at the upper portion of the tailoring device, the tailoring device is located at the upper portion of the bag body cylinder-forming device, the bag body cylinder-forming device and the handlebar machine are located at the upper portion of the gluing forming device, and the gluing forming device is located at the upper portion of the press; the flexible printing device comprises a discharging mechanism, several printing mechanismsand a rolling mechanism, the discharging mechanism is located at the upper portions of the printing mechanisms, and the printing mechanisms are located at the upper portion of the rolling mechanism.The environment-friendly handbag production line is high in automated degree, glue and printing ink are saved, the production cost is lowered, two layers of handlebar bands are firmly pasted to handlebars and the bag body, and the quality of the handbag is guaranteed.

Owner:昆山金红凯包装制品有限公司

Encapsulation casing, substrate, and sealing structure for moisture-sensitive electronic components

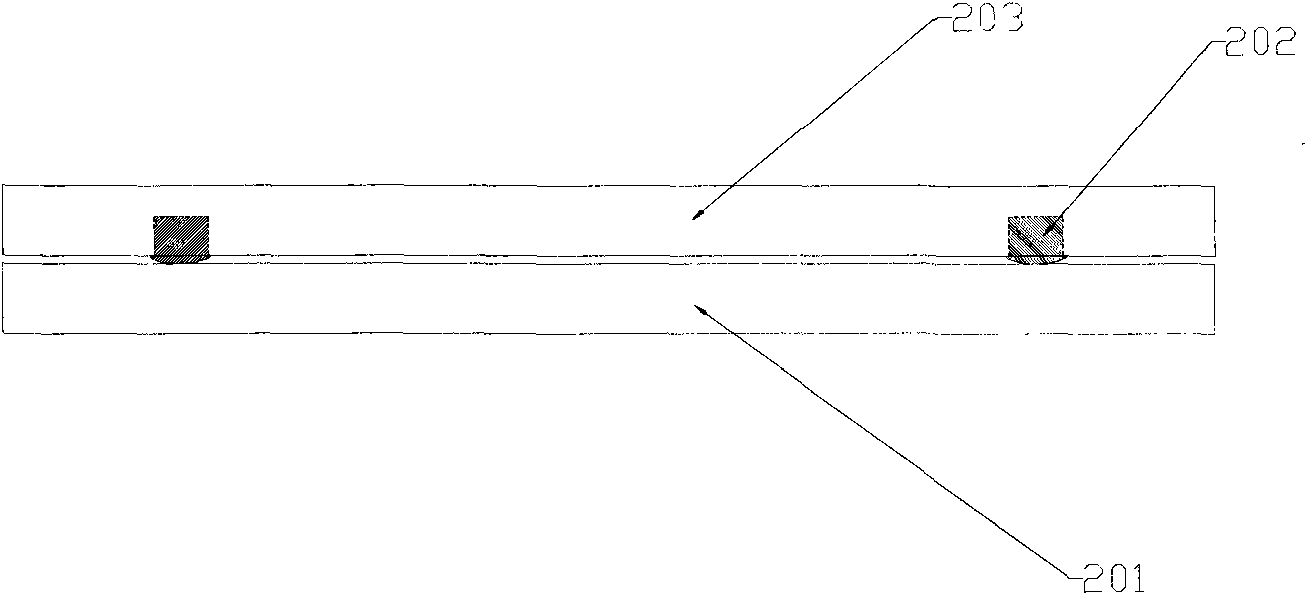

InactiveCN1805130AReduce stickingReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesEngineeringOrganic electroluminescence

The invention relates to a sealing case, base and sealing structure of humidity sensitive electric device, which can reduce the thickness of the part of sealing material that contacting the environment without reducing the thickness of sealing material. The edge of sealing case and / or base comprises one or several grooves to be filled with sealing material; the humidity sensitive electric device can be used in organic electric lighting device, micro electro-mechanical sensor or the charge-coupled device sensor. The invention via preparing the grooves on the base and / or sealing case fills the sealing material into the grooves to reduce the thickness of the part of sealing material that contacting the environment without reducing the thickness of sealing material, to improve the sealing effect without reducing the adhesive property of base and sealing case, and when there are more grooves, the adhesive property and sealing effect can be improved.

Owner:TSINGHUA UNIV +1

Single-side glue spraying device for PE film and using method of single-side glue spraying device

PendingCN112570208APrevent solidificationPrevent large scrollingLiquid surface applicatorsCoatingsStructural engineeringBrush device

The invention discloses a single-face glue spraying device for a PE film. The single-face glue spraying device comprises a device base, a tensioning roller is installed on the left side of the devicebase, the tensioning roller is installed above the device base through a tensioning support, the tensioning support comprises a tensioning screw rod, the tensioning screw rod is installed on one sideof the tensioning support, a roller seat is installed at the upper end of the tensioning screw rod, a tensioning roller is installed at the upper end of the roller seat, the roller seat is slidably connected with the tensioning support, a leveling device is installed on the right side of the tensioning roller, a spraying device is installed on the right side of the leveling roller, a brushing device is installed on the right side of the spraying device, the brushing device comprises a brushing roller, and a smearing device is installed on the right side of the brushing roller and comprises a lower smearing supporting plate and an upper smearing supporting plate, glue waste is reduced, smearing is more uniform, meanwhile, part of glue on the PE film can be recycled, meanwhile, the gluing thickness of the PE film is controlled, the cost is saved, and meanwhile the adhesive force of the glue is increased.

Owner:LINYI JIARUN PLASTIC PROD

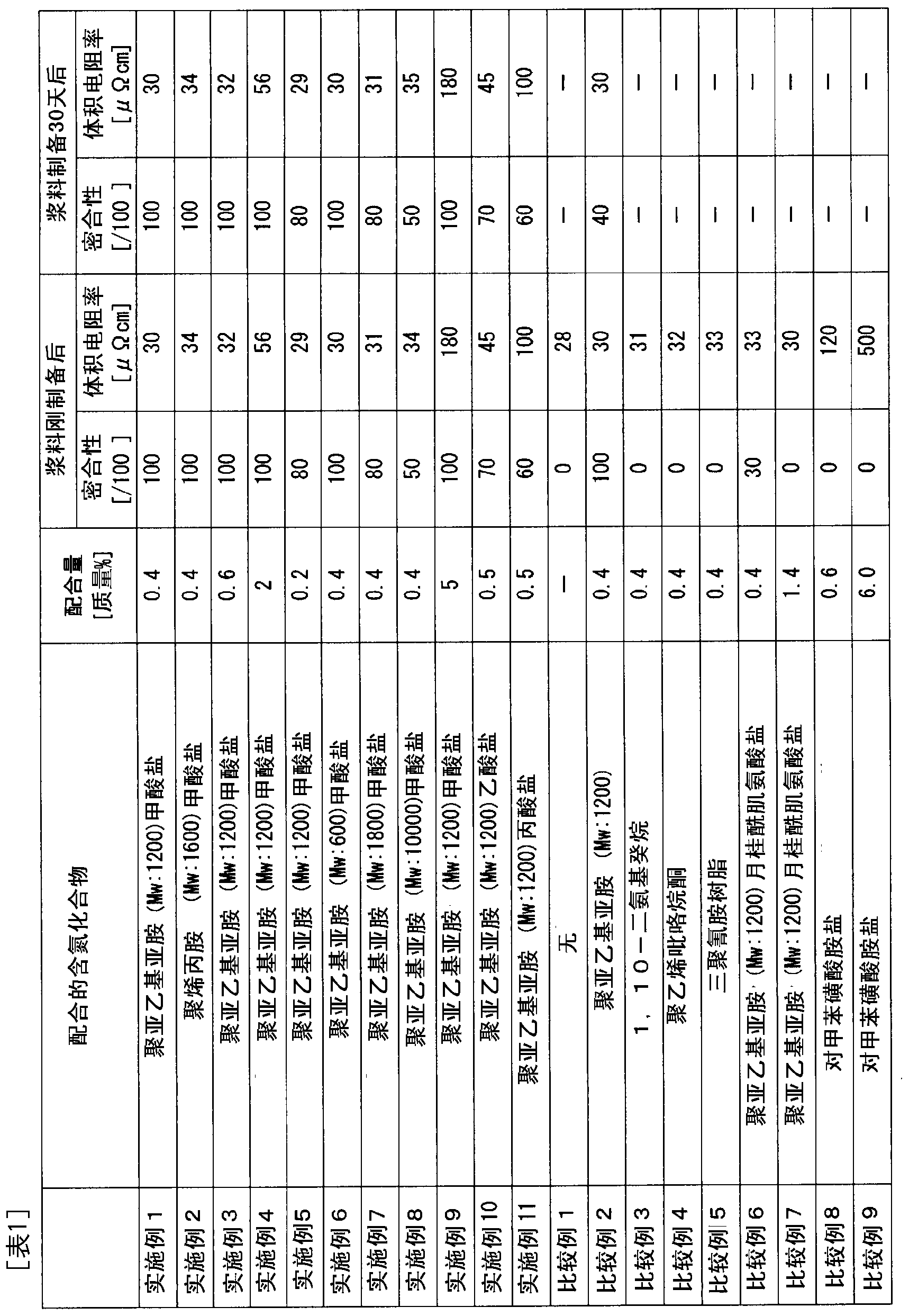

Conductive paste and base with conductive film

ActiveCN103210452AExcellent adhesionImprove conductivityConductive materialNon-conductive material with dispersed conductive materialCarboxylic saltCarboxylic acid

Provided is a conductive paste which exhibits good adhesion by merely being applied over an ITO film directly without the formation of a base layer and being cured thereon and is capable of forming a conductive film that has high conductivity. This conductive paste contains (A) copper particles having an average particle diameter from 10 nm to 20 [mu]m, (B) a carboxylic acid salt of a polymer compound that has at least one primary amino group in each molecule (provided that the carboxylic acid has 10 or less carbon atoms including the carbon atoms of the carbonyl group) and (C) a resin that has an acidic functional group that is reactive with the primary amino group. Specifically, the polymer compound that has primary amino group(s) is preferably a polyethylene imine or a polyallyl amine. In addition, the carboxylic acid salt thereof is preferably a formic acid salt.

Owner:UNKNOWN +1

Anticorrosion and antifouling type coating resin and method for preparing same

ActiveCN108727545AGood anti-corrosion effectGood antifouling effectAntifouling/underwater paintsPaints with biocidesSurface energyEmulsion

The invention discloses anticorrosion and antifouling type coating resin and a method for preparing the same. The method includes adding vinylidene chloride, acrylate, cross-link emulsification monomers, latex protective agents, sodium hydrogen sulfite and water into a container, and uniformly stirring the vinylidene chloride, the acrylate, the cross-link emulsification monomers, the latex protective agents, the sodium hydrogen sulfite and the water to obtain mixed liquid A; mixing acrylic acid monosilane ester, cross-link emulsification monomers and water with one another to obtain mixed liquid B; adjusting the temperature of a reactor until the temperature of the reactor reaches 15-30 DEG C, adding ammonium persulfate and sodium hydrogen sulfite aqueous solution into the reactor in nitrogen atmosphere, dropwise adding the mixed liquid A into the reactor within 3-4 h, then continuing to dropwise add the mixed liquid B and initiators into the reactor for the dropwise adding time of 1-2h, and then keeping the temperature constant for 2-3 h to completely carry out reaction. The anticorrosion and antifouling type coating resin and the method have the advantages that high-stability and high-adhesion emulsion with low surface energy can be prepared from soap-free emulsion at the low temperature under the normal pressure by means of polymerization; the proportions of the vinylidenechloride, different types of acrylate, different types of acrylic acid silyl ester and the cross-link emulsification monomers are adjusted, the capacity such as the adhesion, the water resistance, theweather resistance, the salt resistance and the fouling organism avoidance of resin films can be regulated and controlled, and accordingly the comprehensive performance of anticorrosion and antifouling coating can be improved.

Owner:LUDONG UNIVERSITY

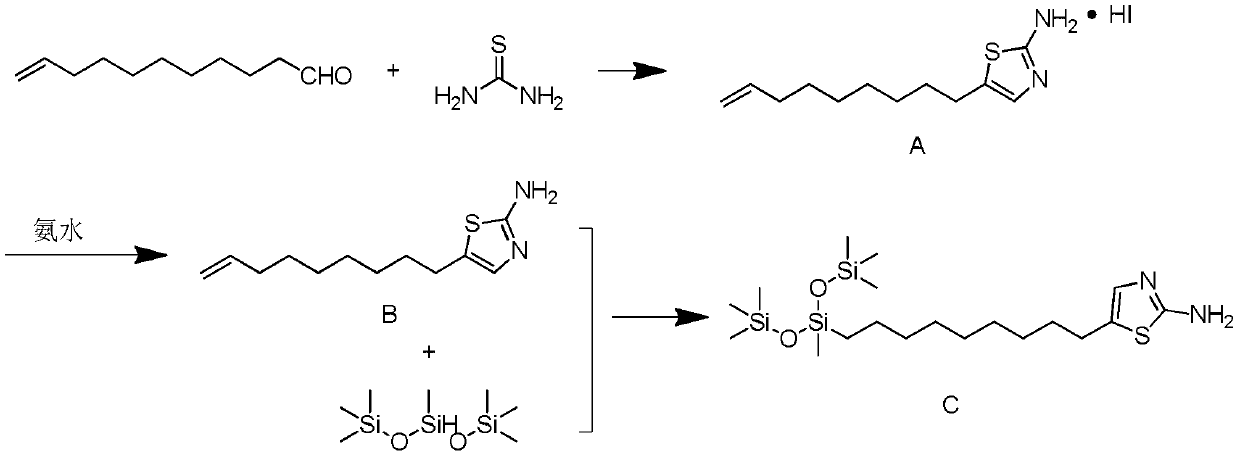

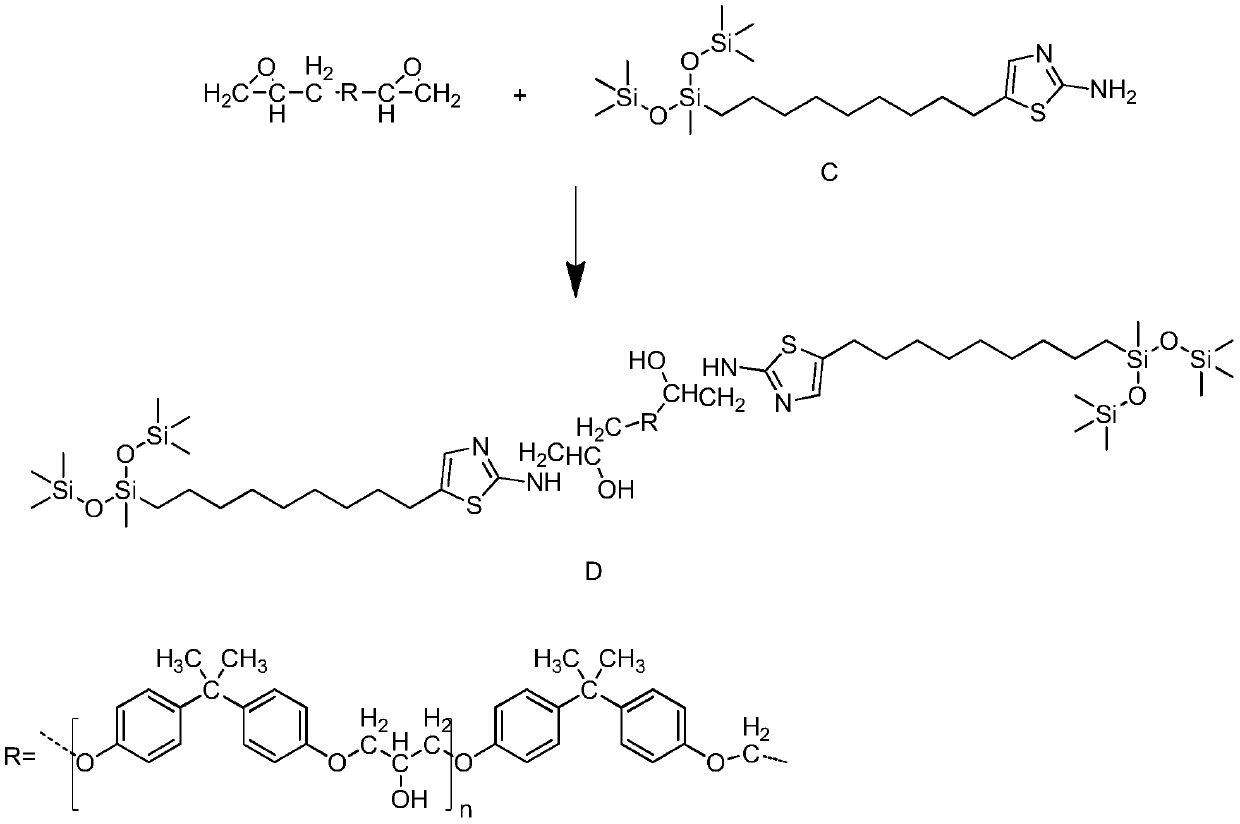

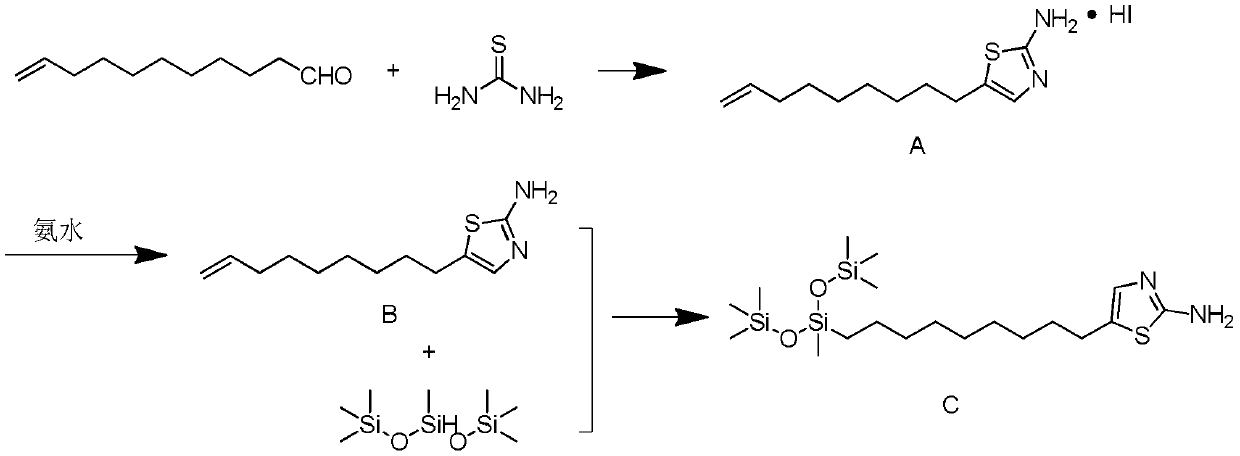

Waterproof mildew-resistant adhesive for food packaging and preparation method thereof

InactiveCN110423586AMaintain antibacterial and antifungal propertiesImprove smellEpoxy resin adhesivesEpoxyOlfactory threshold

The invention discloses a waterproof mildew-resistant adhesive for food packaging and a preparation method thereof. The waterproof mildew-resistant adhesive comprises the following raw materials by weight: 120-130 parts of modified epoxy resin, 7-10 parts of a curing agent and 35-50 parts of deionized water. The antibacterial active group aminothiazole is introduced during the modification of epoxy resin, so the modified epoxy resin has good biological activity and good inhibition effect on bacteria, fungi, mold and acarids; since the active aminothiazole group is introduced into the epoxy resin in the form of a chemical bond, so good firmness is obtained, and the antibacterial and anti-mildew properties of the adhesive can be maintained for a long time; in addition, a thiazole derivativehas odor with distinct characteristics and a thiazole group has a low olfactory threshold and a pleasant smell, so the thiazole derivative is an indispensable ingredient in spices and food, can give out delicate fragrance and whet the appetite when applied to adhesives for outer packaging of food, and has good application prospects.

Owner:苏粤娟

Anti-corrosion concrete

InactiveCN106145793AImprove corrosion resistanceImprove high temperature resistanceEpoxyNitrile rubber

The invention discloses anti-corrosion concrete. The anti-corrosion concrete is prepared from, by weight, 100 parts of modified epoxy resin base fluid, 3-5 parts of vinyl triamine, 10-12 parts of trioctyl citrate, 200-280 parts of river sand, 250-300 parts of pebble, 1-2 parts of hydrogenated nitrile rubber powder, 0.4-0.6 part of polypropylene fiber and 140-160 parts of cement. The anti-corrosion concrete is high in corrosion resistance, high temperature resistance, abrasion resistance and mechanical strength.

Owner:蚌埠市方阵商品混凝土有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com