Sizing material with curing agent for improving stripping performance of S-CLF coiled material

A curing agent and coil technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve problems such as reducing the viscosity of the adhesive, enhance the adhesive strength, solve the defects of peeling strength, and high uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

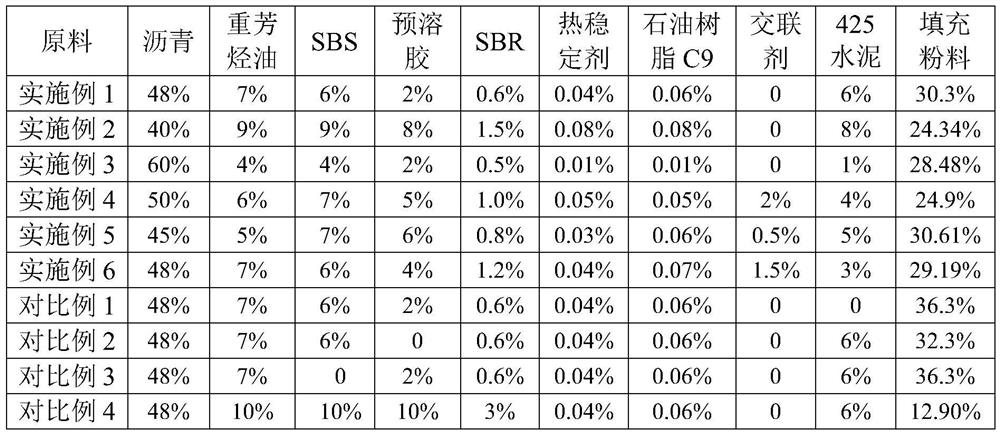

[0060] The formula of sizing material is as table 1, and the preparation method of sizing material comprises the steps:

[0061] S1. Adjust the temperature to 130°C, add asphalt, SBS, presol and SBR, stir at a speed of 5000rpm for 25min, add modified oil and stir evenly at a speed of 2000rpm for 120min.

[0062] S2. Lower the temperature of the system to 85-90°C, add heat stabilizer and modified petroleum resin in sequence, and finally add curing agent and filler powder, stir for 0.5-1h, keep warm, and defoam. The stirring conditions include: the rotating speed is 800 rpm, and the stirring time is 60 min.

Embodiment 2

[0064] The formula of sizing material is as table 1, and the preparation method of sizing material comprises the steps:

[0065] S1. Adjust the temperature to 140°C, add asphalt, SBS, presol and SBR, stir at a speed of 3000rpm for 35min, add modified oil and stir evenly at a speed of 3000rpm for 60min.

[0066] S2. Lower the temperature of the system to 85-90°C, add heat stabilizer and modified petroleum resin in sequence, and finally add curing agent and filler powder, stir for 0.5-1h, keep warm, and defoam. The stirring conditions include: the rotation speed is 1000 rpm, and the stirring time is 30 minutes.

Embodiment 3

[0068] The formula of sizing material is as table 1, and the preparation method of sizing material comprises the steps:

[0069] S1. Adjust the temperature to 135°C, add asphalt, SBS, presol and SBR, stir at a speed of 4000rpm for 30min, add modified oil and stir evenly at a speed of 2500rpm for 100min.

[0070] S2. Lower the temperature of the system to 85-90°C, add heat stabilizer and modified petroleum resin in sequence, and finally add curing agent and filler powder, stir for 0.5-1h, keep warm, and defoam. The stirring conditions include: the rotating speed is 900 rpm, and the stirring time is 50 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com