Under-actuated space capturing mechanism and method

A capture mechanism and underactuated technology, applied in the aerospace field, can solve the problems of difficult to achieve non-cooperative target capture, high requirements for capture control accuracy, and achieve good reusable performance, good shape and size applicability, and wide range. catch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

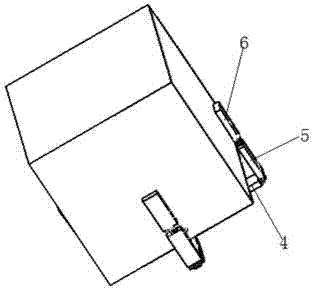

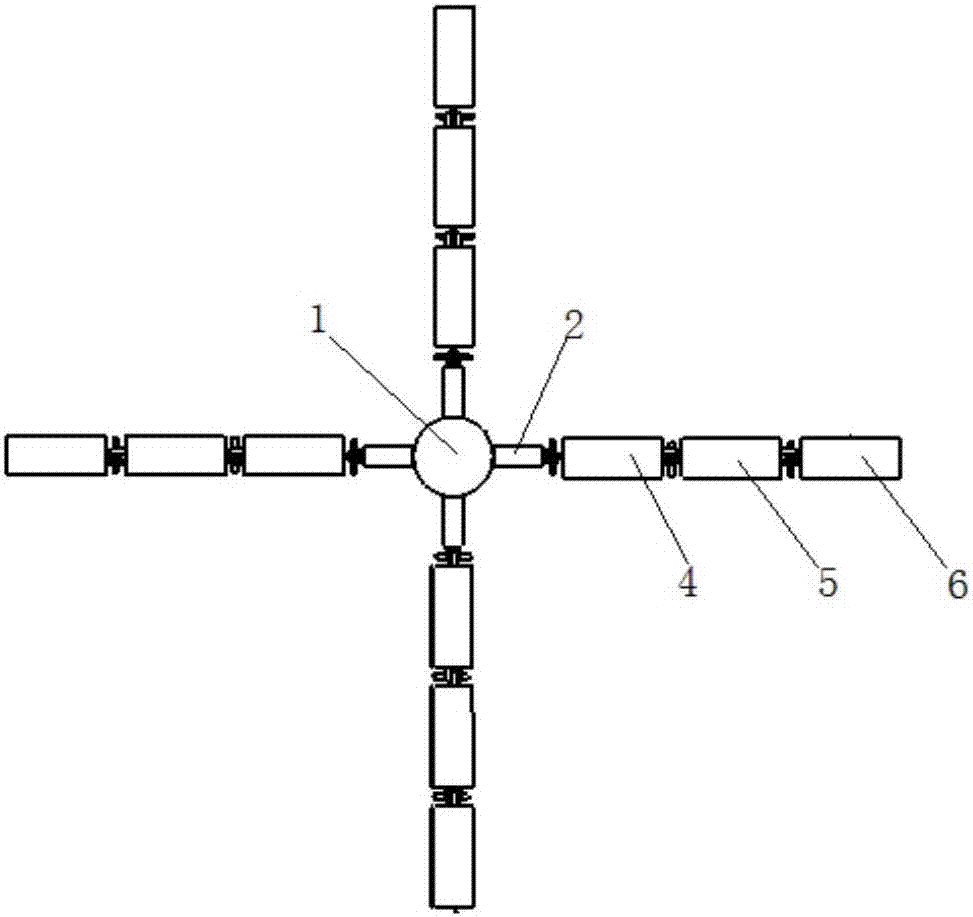

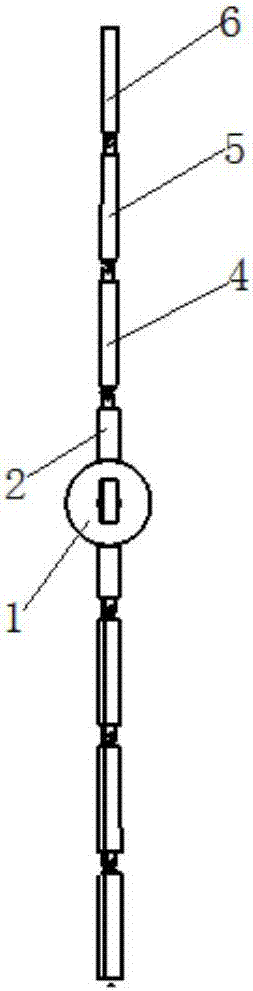

[0052] see Figure 8 , when the mechanism captures a small cube of 400*400*400mm, when it is close to the target and close to the target, the two motors 12 perpendicular to each other in the spherical hinge run, and the driving motor in the second adhesive plate 5 does not run, so the first adhesive plate 4 at this time The second adhesive plate 5 and the third adhesive plate 6 are integrated. The motor 12 in the spherical hinge 1 drives the first adhesive plate 4 to close and rotate through the first worm 2. When the adhesive plate is close to the target object and adheres, the movement stops. Immediately proceed to cleanup tasks or whatever.

Embodiment 2

[0054] see Figure 9 , when the mechanism captures a large cube of 800*800*800mm, when it is close to the target and close to the target, the motor 12 in the spherical hinge 1 does not run, and the driving motor in the second adhesive plate 5 runs. At this time, the first adhesive plate 4 and the spherical hinge 1 , the first worm 2 is a whole, when the second adhesive plate 5 closes and rotates and touches the target object, it first adheres through the adhesive layer on it, and because of the pressure and impact force, the third adhesive plate 6 is under-driven and adhered The plate is closed and rotated, and when the underactuated adhesive plate adheres to the target object, the movement stops, and the cleaning task or other is performed randomly.

[0055] The vertical alignment CNT array prepared by chemical vapor deposition (chemical vapor deposition, CVD) has controllable structure, excellent compression resistance and adhesion performance, and the hierarchical structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com