Wall surface tile incapable of falling off

A ceramic tile and back technology, which is applied in covering/lining, construction, building construction, etc., can solve the problems of reducing the strength of ceramic tiles and failing to achieve firm bonding of cement mortar

Inactive Publication Date: 2017-02-22

JINGMEN CHUANGJIA MACHINERY TECH CO LTD

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The anti-shedding tile patents that have been applied for or authorized at present all adopt the groove-type anti-shedding method. Since the tiles are relatively thin, they are generally 6 to 10 mm thick, and grooves are made within the range of 6 to 10 mm. The effect of firm bonding with cement mortar, and making grooves reduces the strength of tiles

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0010] SUMMARY OF THE INVENTION The specific implementation manners of the present invention have been described in detail and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

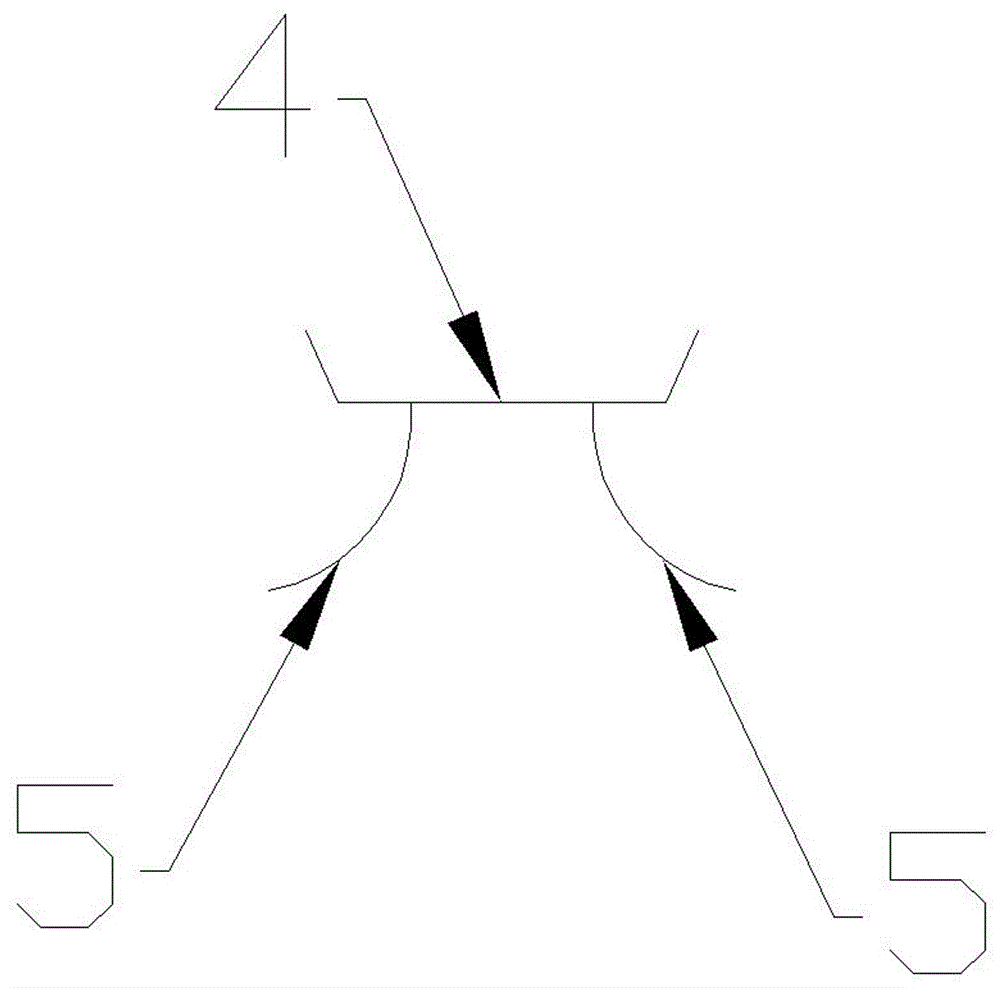

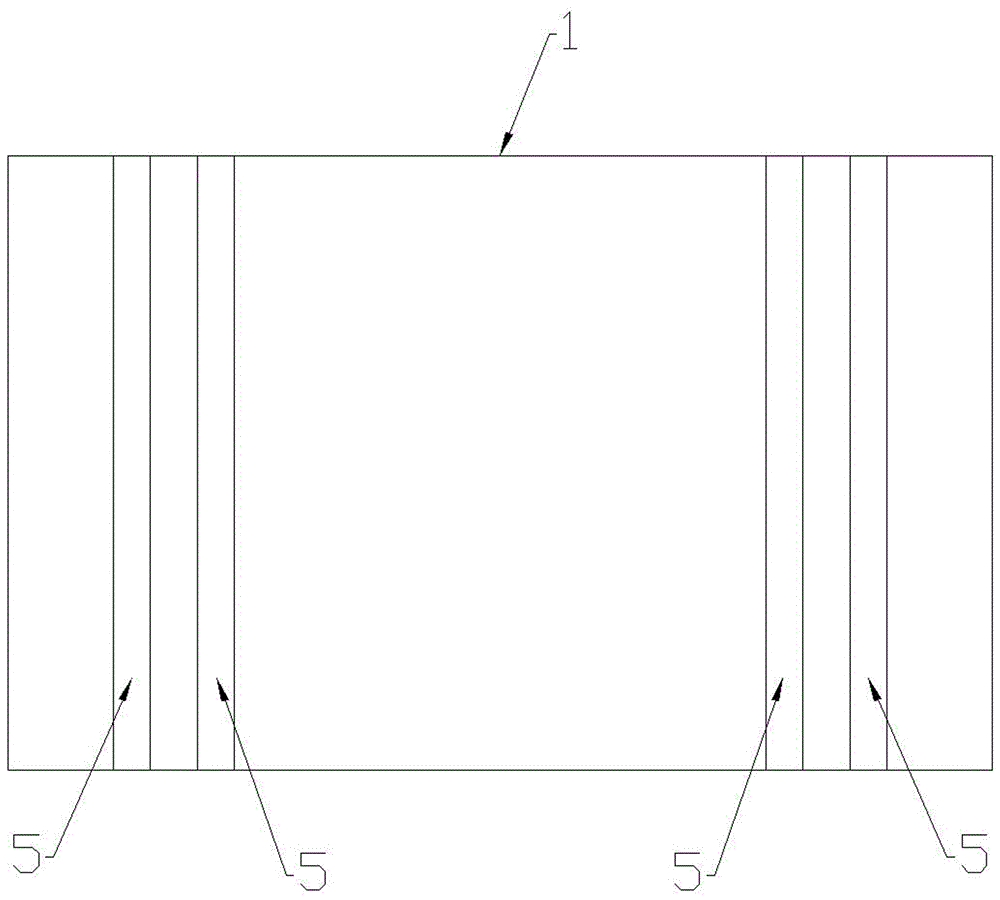

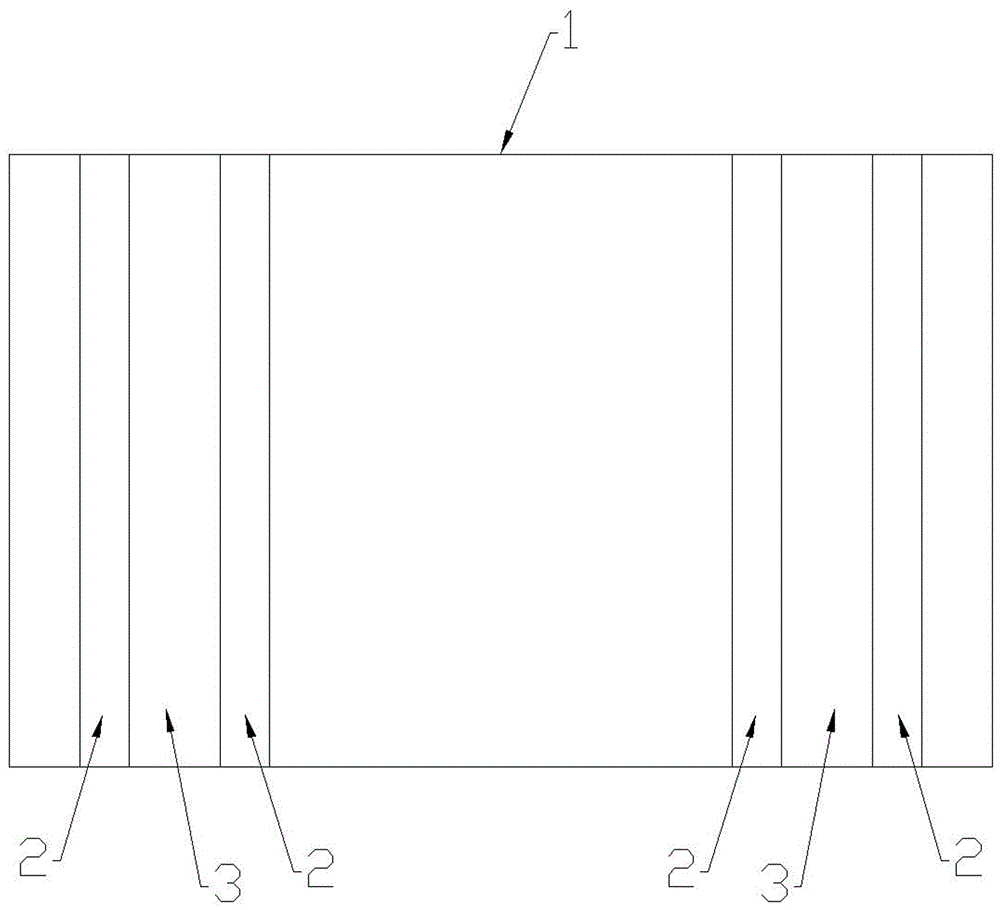

The invention relates to a wall surface tile incapable of falling off and is mainly used in the field of construction engineering decoration. The wall surface tile has the benefits that the strength of the tile cannot be reduced, and the adhesion force of the tile onto cement mortar is strong, so that the tile cannot to fall off. The wall surface tile provided by the invention mainly consists of a tile 1, projecting parts 2, an inverted trapezoidal groove 3, a clamping steel sheet 4 and anchoring legs 5. The wall surface tile adopts a main working principle that the thickness of an original tile is kept unchanged, the plurality of projecting parts 2 are additionally arranged, and the clamping steel sheet 4 is inserted in the inverted trapezoidal groove 3 between the two projecting parts 2; when the tile is adhered, only adhering motor is required to be scraped onto the back surface of the tile, each space of each of the anchoring legs 5 is filled with the adhering motor, and then the tile is adhered onto original cement mortar on a wall surface; antirust coatings are formed on the clamping steel sheet 4 and the anchoring legs 5; as the appearance of each of the circular arc-shaped anchoring legs 5 is simple and smooth, the adhering mortar easily enters all corners of the anchoring leg 5; after the adhering mortar reaches the strength, the anchoring requirements are fully met, so that the tile cannot fall off.

Description

technical field [0001] The invention is mainly used in the field of architectural engineering decoration. Background technique [0002] The anti-shedding tile patents that have been applied for or authorized at present all adopt the groove-type anti-shedding method. Since the tiles are relatively thin, they are generally 6 to 10 mm thick, and grooves are made within the range of 6 to 10 mm. It has the effect of firmly bonding with cement mortar, and making grooves reduces the strength of tiles. Contents of the invention [0003] The present invention solves the above-mentioned problems, it will not reduce the strength of the tiles, and has strong adhesion with cement mortar, ensuring that the tiles will not fall off; the present invention mainly consists of tiles (1), protrusions (2), inverted trapezoidal grooves (3 ), clamping steel sheet (4), and anchoring feet (5); the lower end of the ceramic tile (1) has multiple protrusions (2), and two symmetrical protrusions (2) f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04F13/14

CPCE04F13/14

Inventor 彭宝安

Owner JINGMEN CHUANGJIA MACHINERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com