High-temperature resistant sectional curing epoxy paint and use method thereof

A technology of high temperature resistant epoxy paint, applied in the direction of epoxy resin coating, coating, fireproof coating, etc., can solve the problems of paint film strength, poor adhesion, affecting paint film quality, uneven paint film, etc., to achieve Reminder of thermal conductivity, increase contact probability, and smooth paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

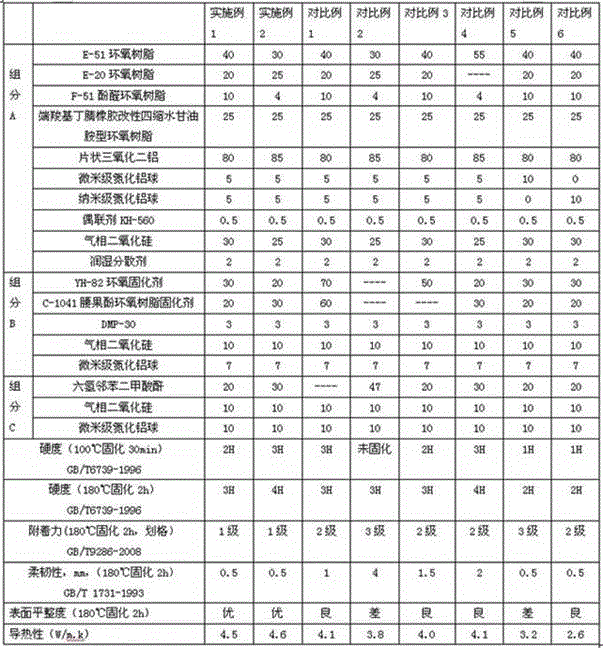

Examples

Embodiment 1

[0027] 1) Preparation of component A:

[0028] The A component is an epoxy resin component, which is composed of the following raw materials by weight: 20 parts of E-20 bisphenol A epoxy resin, 40 parts of E-51 bisphenol A epoxy resin, F-51 phenolic ring 10 parts of oxygen resin, 25 parts of carboxyl-terminated nitrile rubber modified tetraglycidylamine epoxy resin, 80 parts of flake aluminum oxide, 5 parts of micron aluminum nitride balls, 5 parts of nanometer aluminum nitride balls, 30 parts of fumed silica, 2 parts of wetting and dispersing agent, 0.5 part of coupling agent KH-560. The components are uniformly mixed in a vacuum mixer and packaged for use;

[0029] The carboxyl-terminated nitrile rubber modified tetraglycidylamine epoxy resin is composed of 25 parts by weight of carboxyl-terminated nitrile rubber and 75 parts by weight of tetraglycidylamine type multifunctional epoxy resin, using triphenylphosphine as a catalyst , after reacting at 120 ° C for 1 hour, it i...

Embodiment 2

[0037] 1) Preparation of component A:

[0038] The A component is an epoxy resin component, which is composed of the following raw materials by weight: 25 parts of E-20 bisphenol A epoxy resin, 30 parts of E-51 bisphenol A epoxy resin, F-51 phenolic ring 4 parts of oxygen resin, 25 parts of carboxyl-terminated nitrile rubber modified tetraglycidylamine epoxy resin, 85 parts of flake aluminum oxide, 5 parts of micron aluminum nitride balls, 5 parts of nanometer aluminum nitride balls, 25 parts of fumed silica, 2 parts of wetting and dispersing agent, 0.5 part of coupling agent KH-560. The components are uniformly mixed in a vacuum mixer and packaged for use.

[0039] The carboxyl-terminated nitrile rubber modified tetraglycidylamine-type epoxy resin is composed of 28 parts by weight of carboxyl-terminated nitrile rubber and 72 parts by weight of tetraglycidylamine-type multifunctional epoxy resin, using triphenylphosphine as a catalyst , after reacting at 130 ° C for 0.5 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com