Encapsulation casing, substrate, and sealing structure for moisture-sensitive electronic components

A technology for encapsulating shells and electronic devices, which is applied in the directions of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of reducing the adhesion performance of substrates and encapsulation shells, and achieve good adhesion performance, packaging effect, and packaging effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

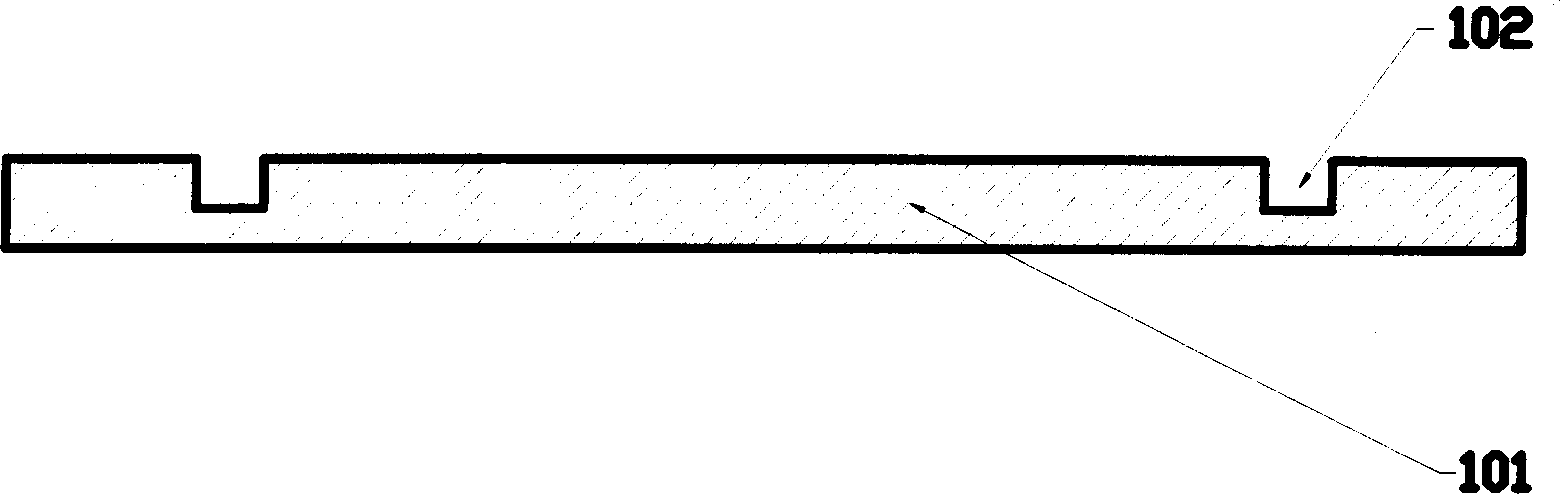

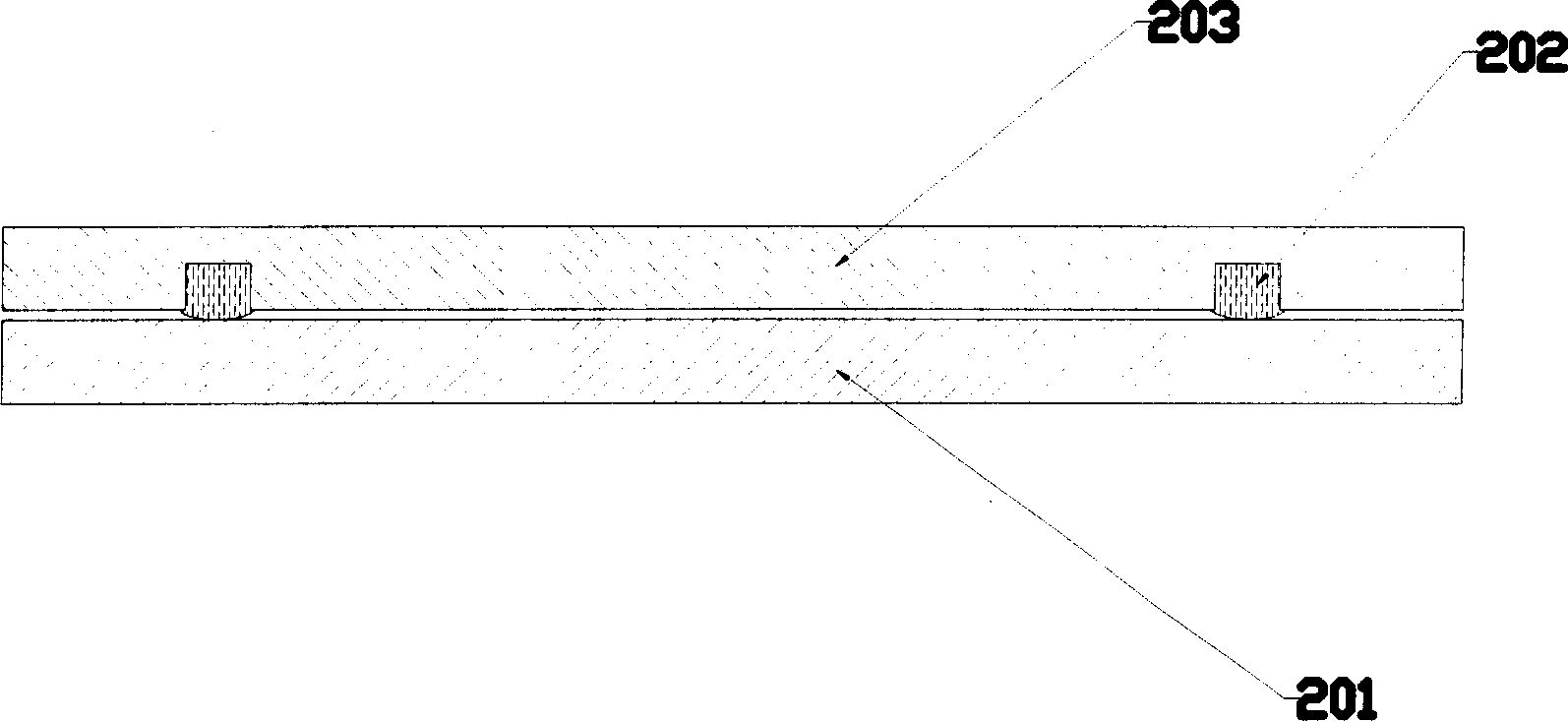

[0020] Glass substrate / ITO / NPB(50nm) / Alq(50nm) / Mg:Ag / glass sheet with a ring of grooves

[0021] (1) Cleaning of glass substrates pre-engraved with ITO: use hot detergent ultrasonic and deionized water ultrasonic methods to clean the transparent conductive substrate ITO glass, place it under an infrared lamp to dry after cleaning, and then The dried ITO glass is pretreated by ultraviolet ozone cleaning and low-energy oxygen ion beam bombardment. The ITO film on the conductive substrate is used as the anode layer of the device. The square resistance of the ITO film is 50Ω and the film thickness is 150nm;

[0022] (2) Preparation of the organic light-emitting layer: the above-mentioned cleaned and dried ITO glass that has been pretreated is placed in a vacuum chamber, and the vacuum is evacuated to 1×10 -3 Pa, and then evaporate a layer of hole transport material NPB on the above-mentioned ITO film, the evaporation rate of the material film is 0.5nm / s, and the film thickness is ...

Embodiment 2

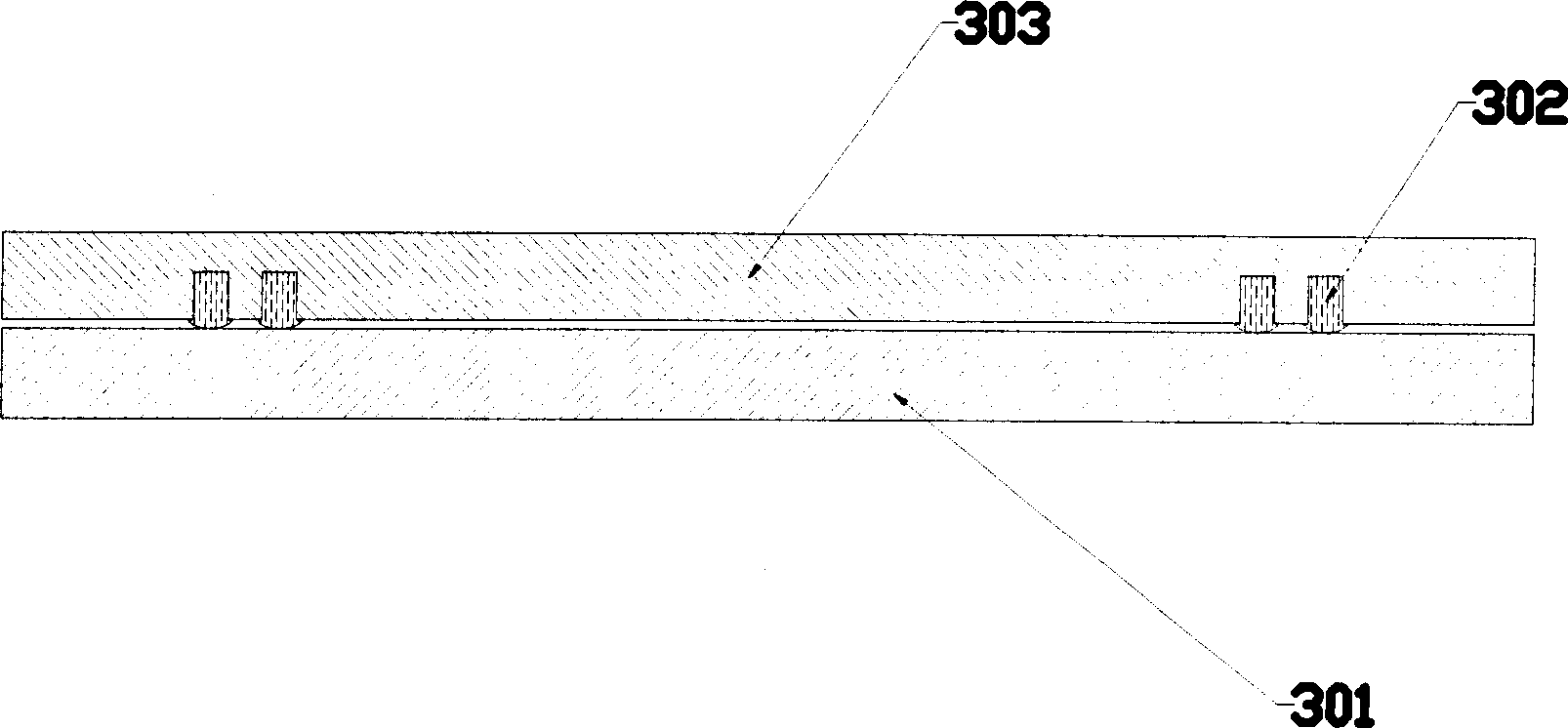

[0026] Glass substrate / ITO / NPB / Alq / Mg:Ag / PI / glass sheet with two grooves

[0027] The preparation steps are the same as in Example 1, except that two circles of grooves 302 with a depth of 1 mm and a width of 0.75 mm are made on the packaging glass 303, glue is dispensed on the two circles of grooves, and then the packaging glass 303 is pressed together and the substrate 301, the thickness of the sealing material exposed to gas was 4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com