Conductive paste and base with conductive film

A technology of conductive paste and base material, applied in the direction of conductive materials, conductive materials, conductive materials, etc. dispersed in non-conductive inorganic materials, can solve the problem that ITO film fails to show good adhesion, ITO film fails to show Avoid problems such as adhesion, and achieve the effect of excellent storage stability and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

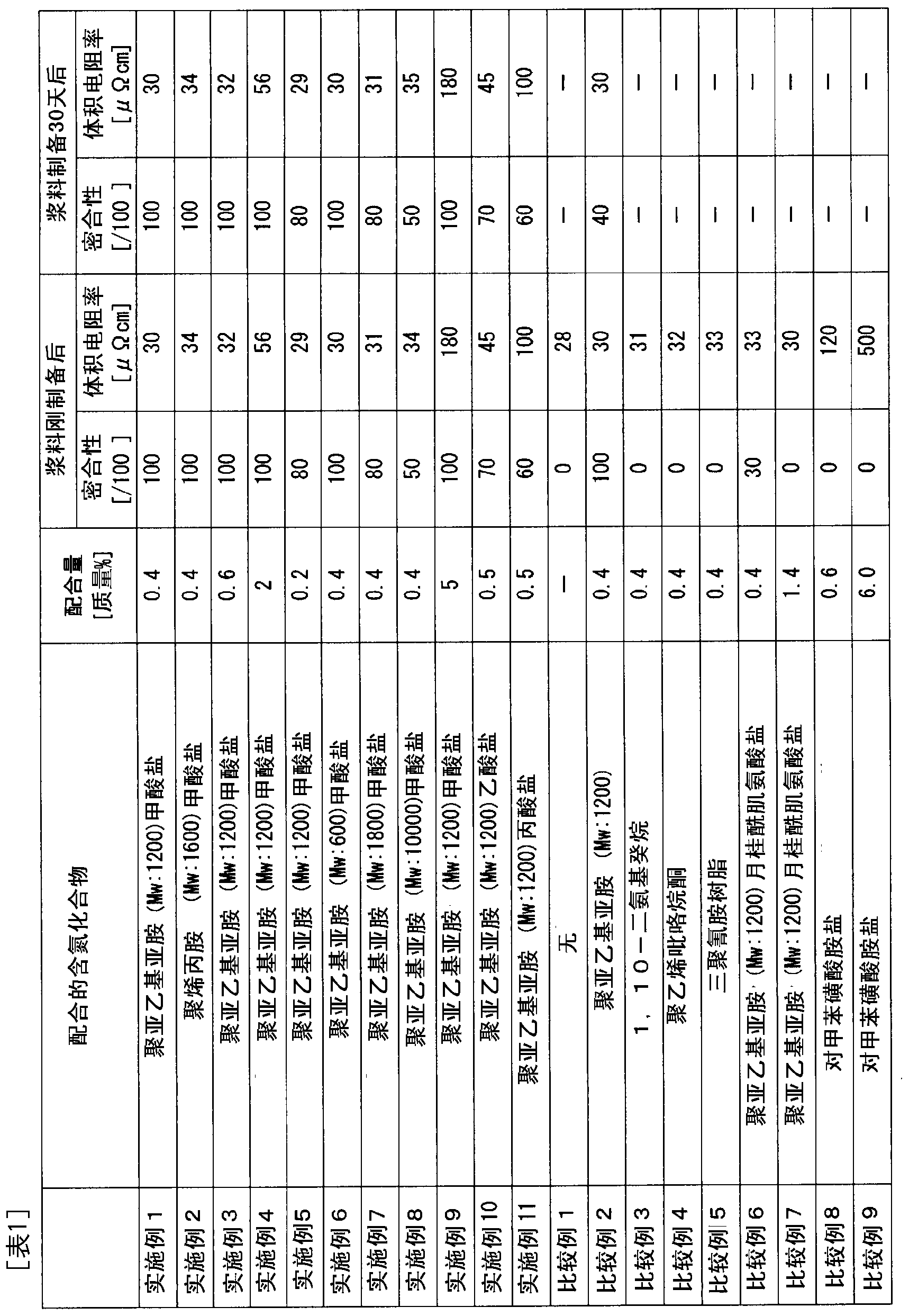

Embodiment 1

[0173] A glass beaker was placed in a water bath whose water temperature was set at 50° C., and 50 g of polyethyleneimine (manufactured by Nippon Catalyst Co., Ltd., trade name: SP012, Mw: 1200, amine value: 1064 mgKOH / g) was added to the beaker. While vigorously stirring, 43 g of formic acid was slowly added dropwise. The above-mentioned polyethyleneimine, which was pale yellow, reacted violently while emitting smoke, and turned into a brown liquid. After completion of the dropwise addition, the mixture was stirred for 30 minutes in this state, and the product was recovered in a glass container. The weight becomes the sum of polyethyleneimine and formic acid, and the product is observed by FT-IR (manufactured by Nicolet, Avatar370). As a result, it appears at 1700cm -1 The nearby carbonyl peaks derived from carboxylic acids disappear. From this, it was confirmed that a salt of polyethyleneimine and formic acid was produced.

[0174] 3.0 g of formic acid and 9.0 g of 50 mas...

Embodiment 2

[0179] A glass beaker was placed in a water bath whose water temperature was set at 50° C., and polyallylamine (manufactured by Nittobo Co., Ltd., trade name: PAA-01, Mw: 1600, amine value: 1120 gKOH / g, 15 mass % aqueous solution) 50g, slowly drop formic acid 6.5g while vigorously stirring. The light yellow polyallylamine reacted violently while emitting smoke, and turned into a brown liquid. After completion of the dropwise addition, the mixture was stirred for 30 minutes in this state, and then, the product was recovered in an eggplant-shaped flask. The product was dried at 50° C. for 24 hours in an eggplant-shaped flask to obtain a formate salt of polyallylamine after drying.

[0180]Next, 12 g of surface-modified copper particles (A-1) obtained in the same manner as in Example 1 were added to a resin solution obtained by dissolving 7.4 g of phenolic resin in 4.3 g of ethylene glycol monobutyl ether acetate, and then , 0.05 g of the formate salt of the polyallylamine obta...

Embodiment 3

[0182] A polyethyleneimine formate was prepared in the same manner as in Example 1, except that the addition amount of the polyethyleneimine formate was set to 0.07 g, and a copper paste was obtained in the same manner as in Example 1 material. In addition, the compounding quantity of polyethyleneimine formate was 0.6 mass % with respect to copper particle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com