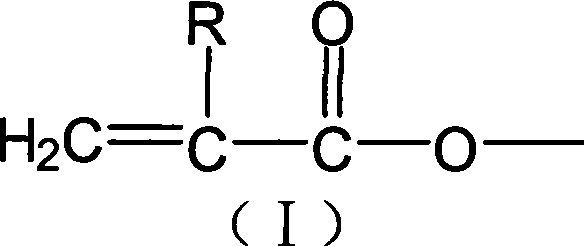

Ultraviolet ray/anaerobic dual curing binding agent and preparation method thereof

A dual-curing, adhesive technology, applied in the direction of non-polymer organic compound adhesives, adhesives, etc., can solve the problems of slow anaerobic curing rate, poor surface dryness of adhesives, affecting strength, etc. Broad application prospects, high-efficiency anaerobic curing performance, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 40 parts of triethylene glycol dimethacrylate, 60 parts of epoxy acrylate oligomer, 0.05 parts of hydroquinone, 0.5 parts of acetophenhydrazine, 0.5 parts of tri-n-butylamine, 0.1 parts of ascorbic acid, o-sulfonyl Mix and stir 1 part of benzimide until dissolved, then add 3 parts of photoinitiator α,α-dimethyl-α-hydroxyacetophenone, and finally add 2 parts of cumene hydroperoxide at a temperature lower than 40°C , after mixing evenly, divide into black low-density polyethylene bottles, up to 2 / 3 bottles.

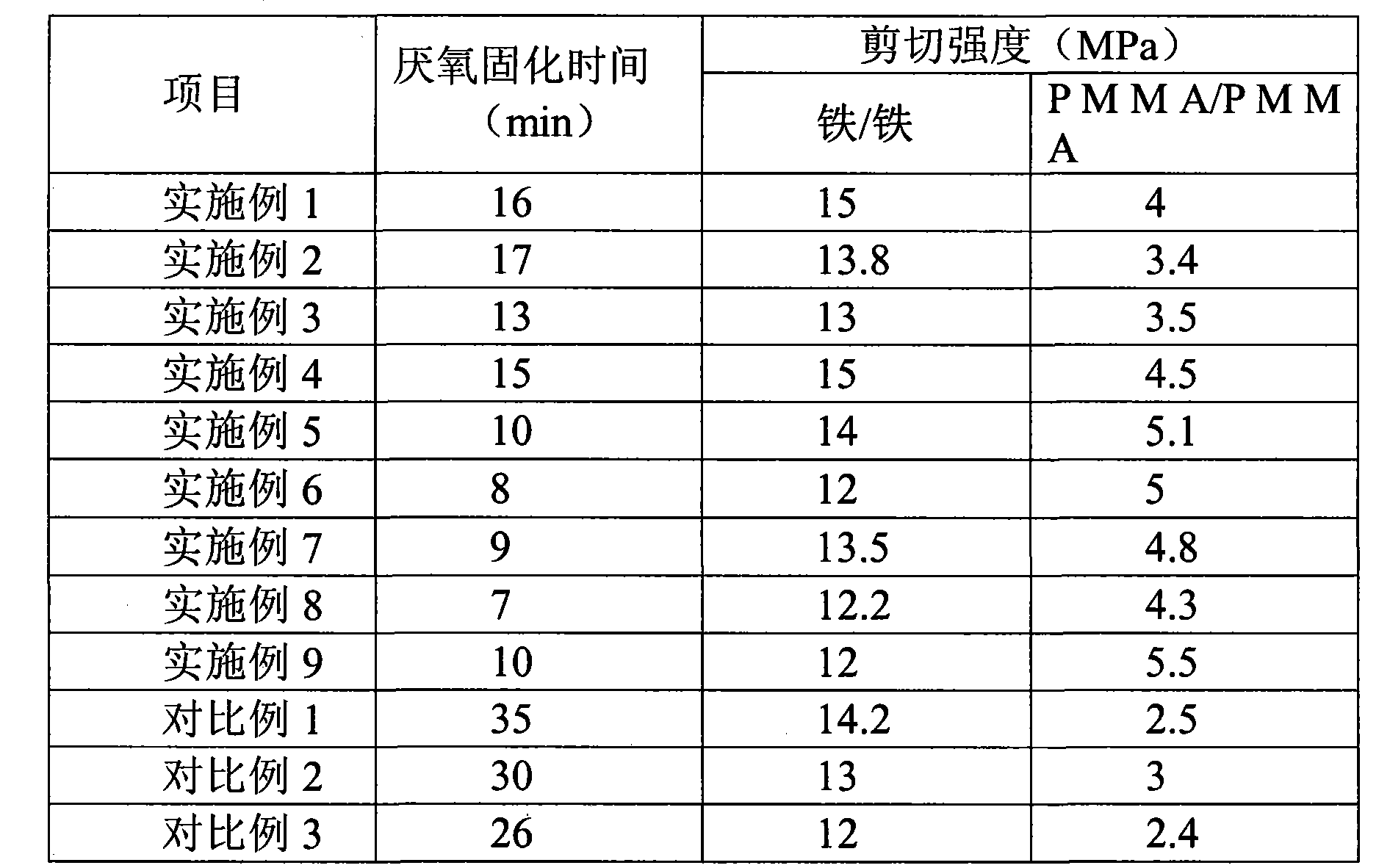

[0035] Embodiment 2~9, according to the formula quantity sampling preparation shown in table 1, preparation method is the same as embodiment 1.

[0036] The adhesive prescription of table 1 embodiment 2~9

[0037] Example 2 3 4 5 6 7 8 9 epoxy acrylate 60 60 -- 60 -- -- 60 -- urethane acrylate -- -- 60 -- 60 60 -- 60 Hydroxyethyl methacrylate 40 -- 40 -- -- 20 20 --

[0038] 2-phenoxyethyl acryla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com