Asphalt concrete pavement structure and laying technology thereof

A technology of asphalt concrete and pavement structure, which is applied to the coagulation pavement, roads, roads and other directions paved on site, can solve the problems of poor temperature stability and poor water stability, and achieves good temperature stability, uniform stress and water storage. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

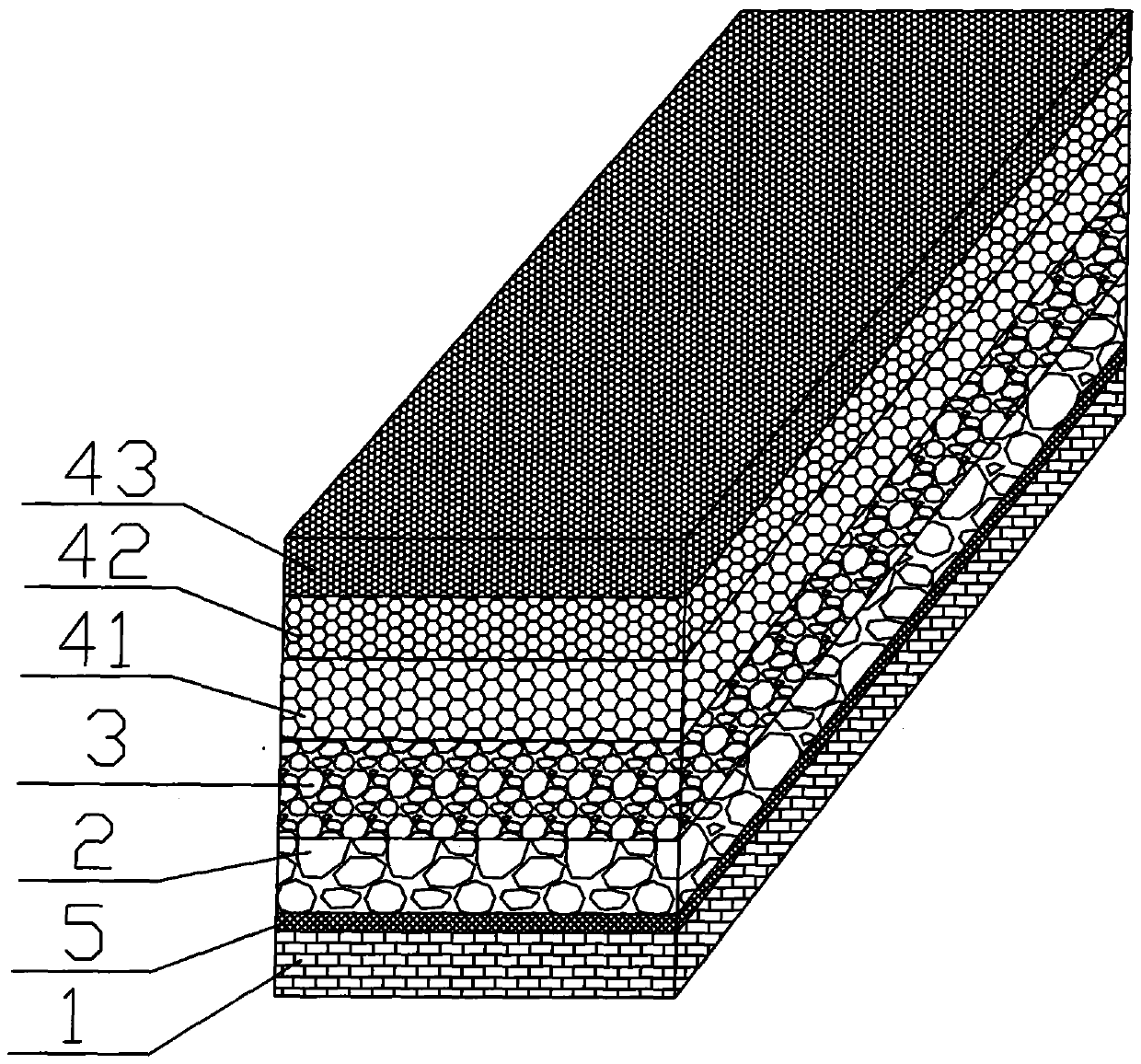

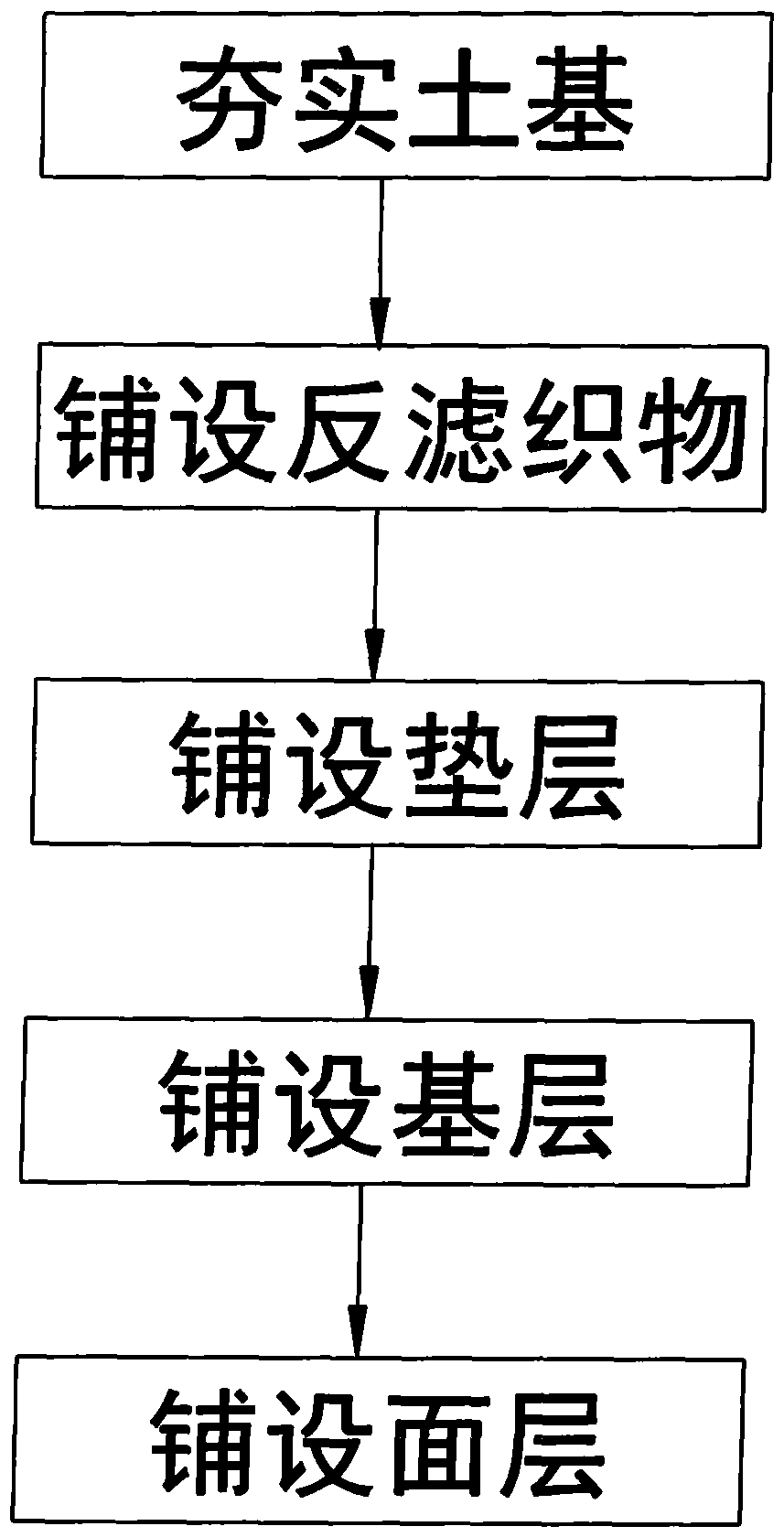

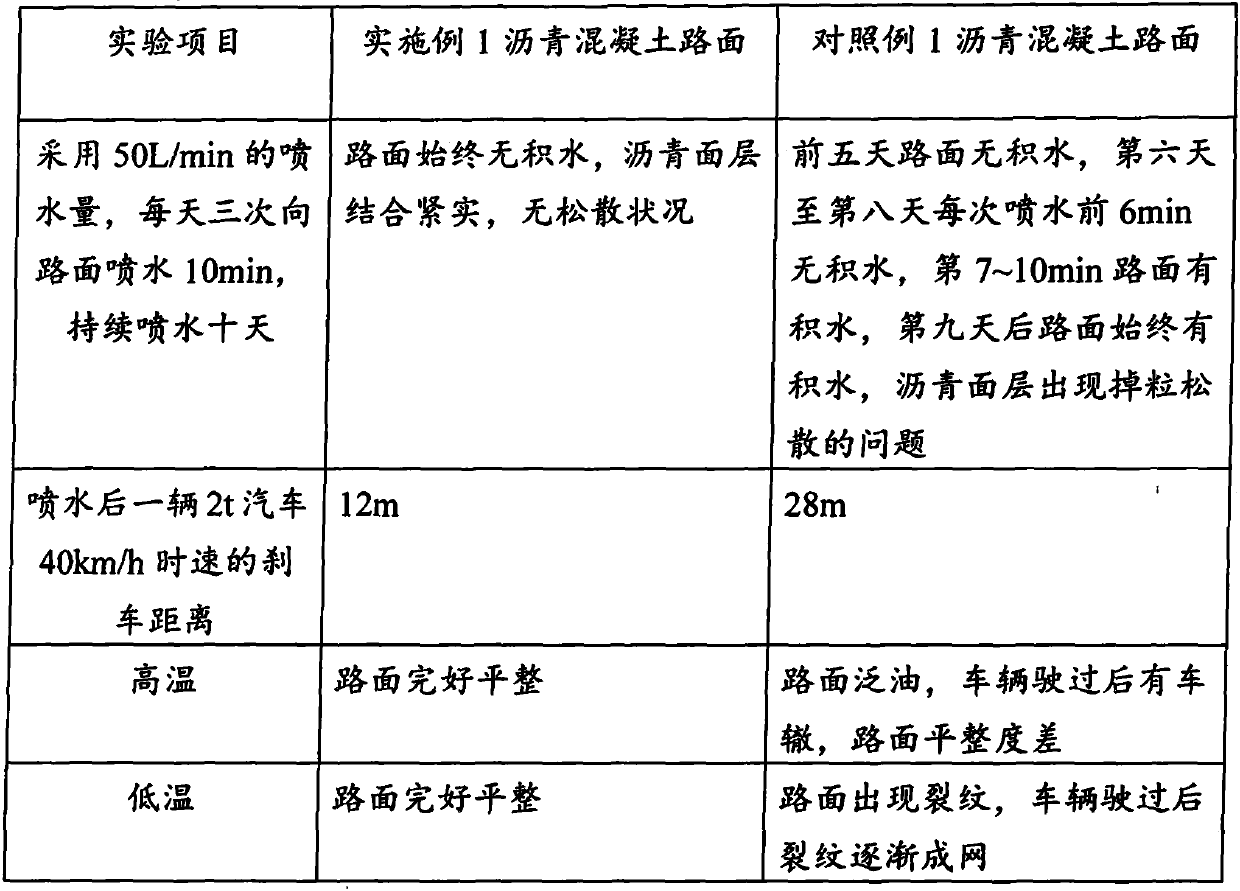

[0036] This embodiment provides an asphalt concrete pavement structure, such as figure 1 As shown, including the soil foundation 1, the top of the soil foundation 1 is successively laid with a cushion layer 2, a base layer 3 and a surface layer 4, and a layer of filter fabric 5 is laid between the soil foundation 1 and the cushion layer 2. The filter fabric 5 adopts non-woven geotextile, and the specification is 300g / m 2 , its function is to prevent the fine soil from entering the soil foundation 1 and causing damage to the soil foundation 1. The cushion layer 2 is made of building concrete slag, and the width of the cushion layer 2 is 25cm wider than the side of the soil foundation 1. The base layer 3 is made of crushed stone slag Mixture, the width of the base layer 3 is consistent with the width of the cushion layer 2, and the width of the surface layer 4 is narrower than the side 5cm of the base layer 3 on each side; the surface layer 4 includes a lower layer 41, a middle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com