Solvent-based release coating-forming organopolysiloxane composition and release film or sheet

A technology based on hydrogen polysiloxane, anti-stick coating, applied in the direction of coating, heat-activated film/sheet, film/sheet release liner, etc., which can solve the problem of satisfactory application and large peeling off of anti-stick coating To avoid problems such as force, damage, stickiness or adhesion of adhesive materials, to achieve excellent peeling performance and light peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

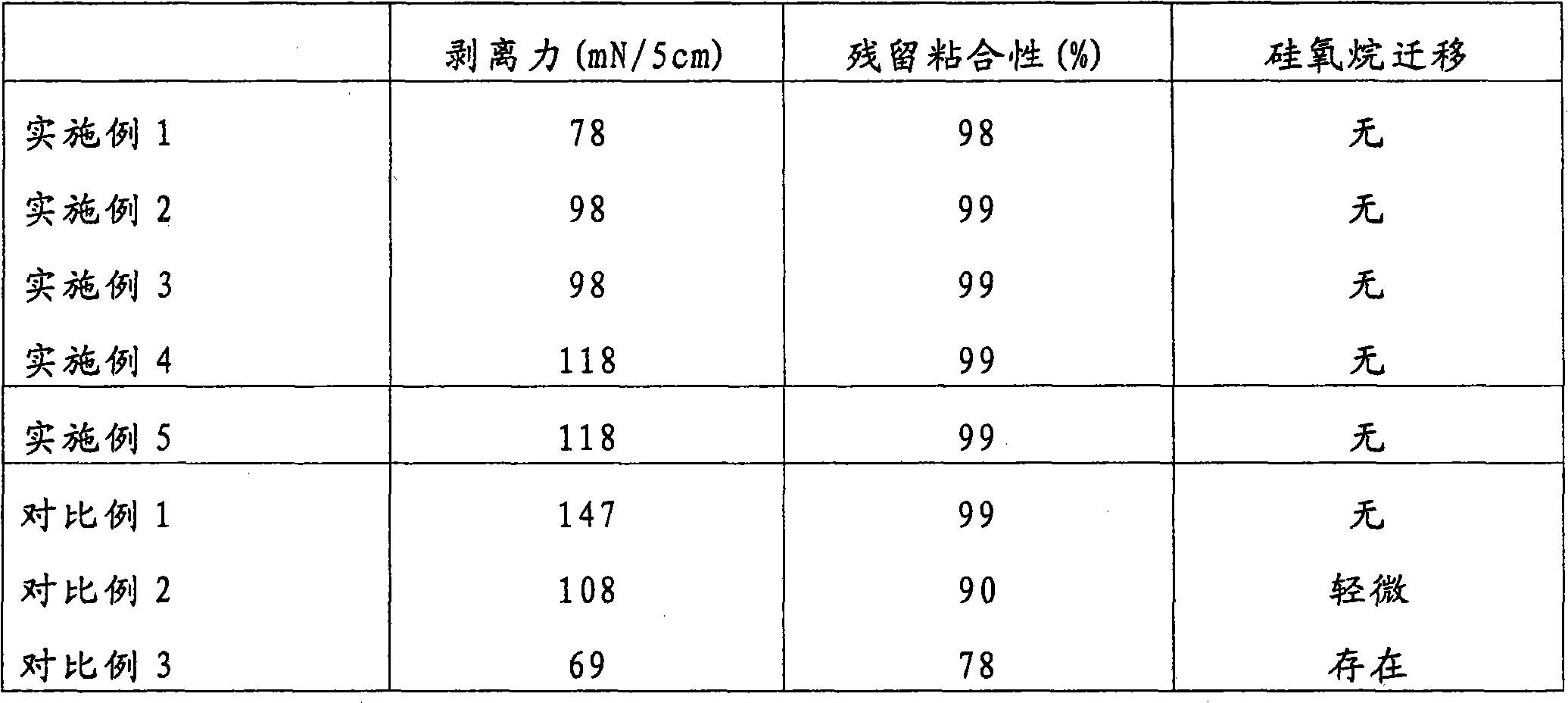

[0105] 100 parts by weight of a dimethylsiloxane-methylhexenylsiloxane copolymer (the viscosity of the 30wt% toluene solution of the copolymer=5,000mPa • s) (A1) was dissolved in 275.44 parts by weight of toluene (E1). Then, the following was added to the resulting solution and dissolved until uniform: 2.4 parts by weight of methylhydrogenpolysiloxane (silicon-bonded hydrogen content = 1.6 % by weight, viscosity = 20 mPa·s) (B1), 20 parts by weight of linear dimethylpolysiloxane (silicon-bonded hydrogen content = 0.01 % by weight, viscosity=400 mPa·s) (C1), 2 parts by weight of 3-methyl-1-butynyl-3-ol (G1) and 0.16 parts by weight of diethoxyacetophenone (F1). Chloroplatinic acid / 1,3-divinyltetramethyldisiloxane complex (D1) was additionally mixed in an amount to provide 200 ppm of platinum metal, thereby producing a solvent-borne silicone that forms a cured release coating. Oxane composition [1]. Cured coatings were prepared from this composition by the method described pr...

Embodiment 2

[0107] The solvent-borne silicone composition [2] for forming a cured release coating was prepared as described in Example 1, but in this case using 10 parts by weight of a dimethylhydrogensiloxy-capped at both ends of the molecule. Linear polysiloxane (silicon-bonded hydrogen content = 0.01 wt%, viscosity = 400 mPa·s) (C1) instead of 20 parts by weight of this component used in Example 1 (C1). Cured coatings were prepared from this composition by the method described previously and the resulting cured coatings were evaluated for peel force, residual adhesion (%) and silicone migration; the results are shown in Table 1.

Embodiment 3

[0109] The solvent-borne, cured release coating-forming silicone composition [3] was prepared as described in Example 1, but in this case using 20 parts by weight of a dimethylhydrogensiloxy-capped at both ends. Linear dimethyl polysiloxane (silicon-bonded hydrogen content = 0.02 wt%, viscosity = 135 mPa·s) (C2), instead of the 20 parts by weight used in Example 1, both ends of the molecule are composed of two Methylhydrogensiloxy-terminated linear dimethylpolysiloxane (silicon-bonded hydrogen content = 0.01 wt%, viscosity = 400 mPa·s) (C1). Cured coatings were prepared from this composition by the method described previously and the resulting cured coatings were evaluated for peel force, residual adhesion (%) and silicone migration; the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com