Structure and applications of high tensile strength and fast curing adhesive for metal surface

A high tensile strength, fast curing technology, used in adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of poor toughness, slow curing, and cannot be widely used, and achieve the effect of improving tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

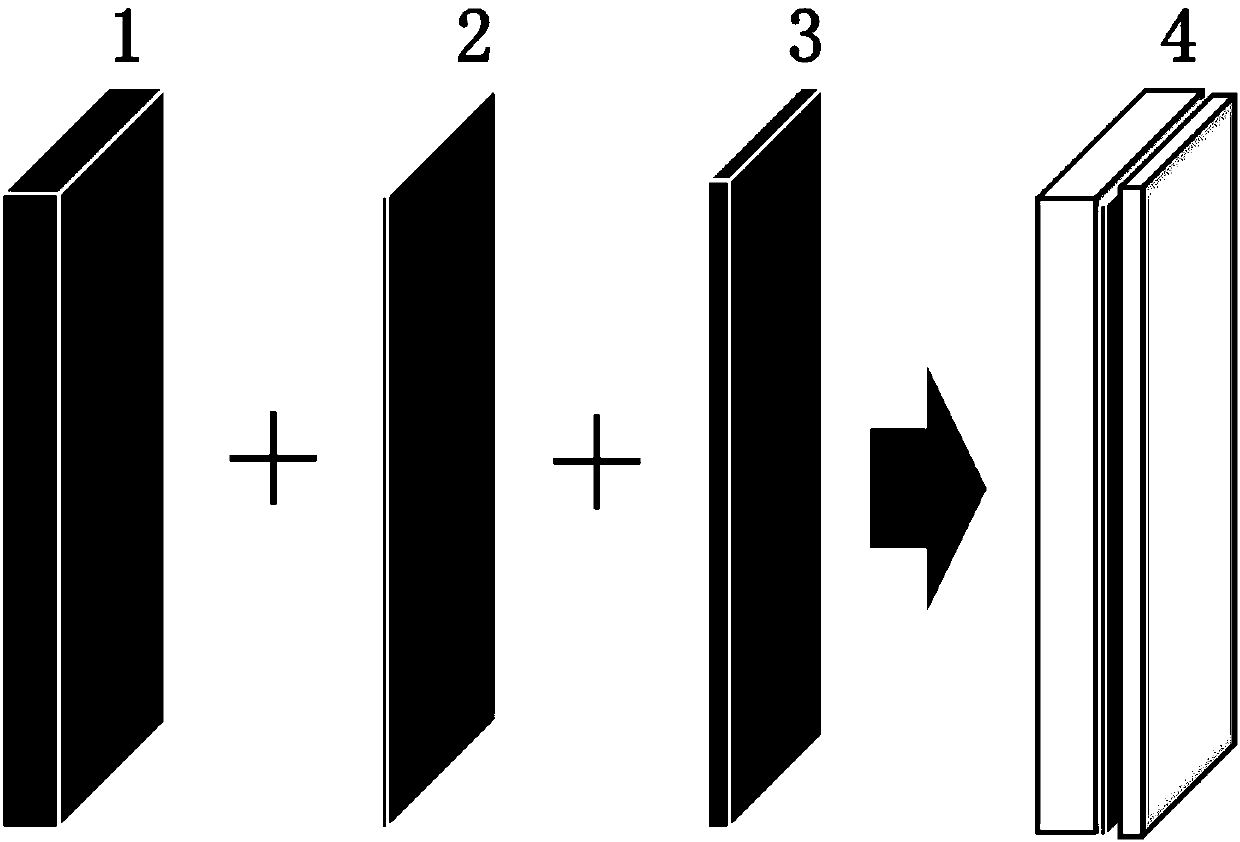

Image

Examples

Embodiment 1

[0031] Experiment No. J1:

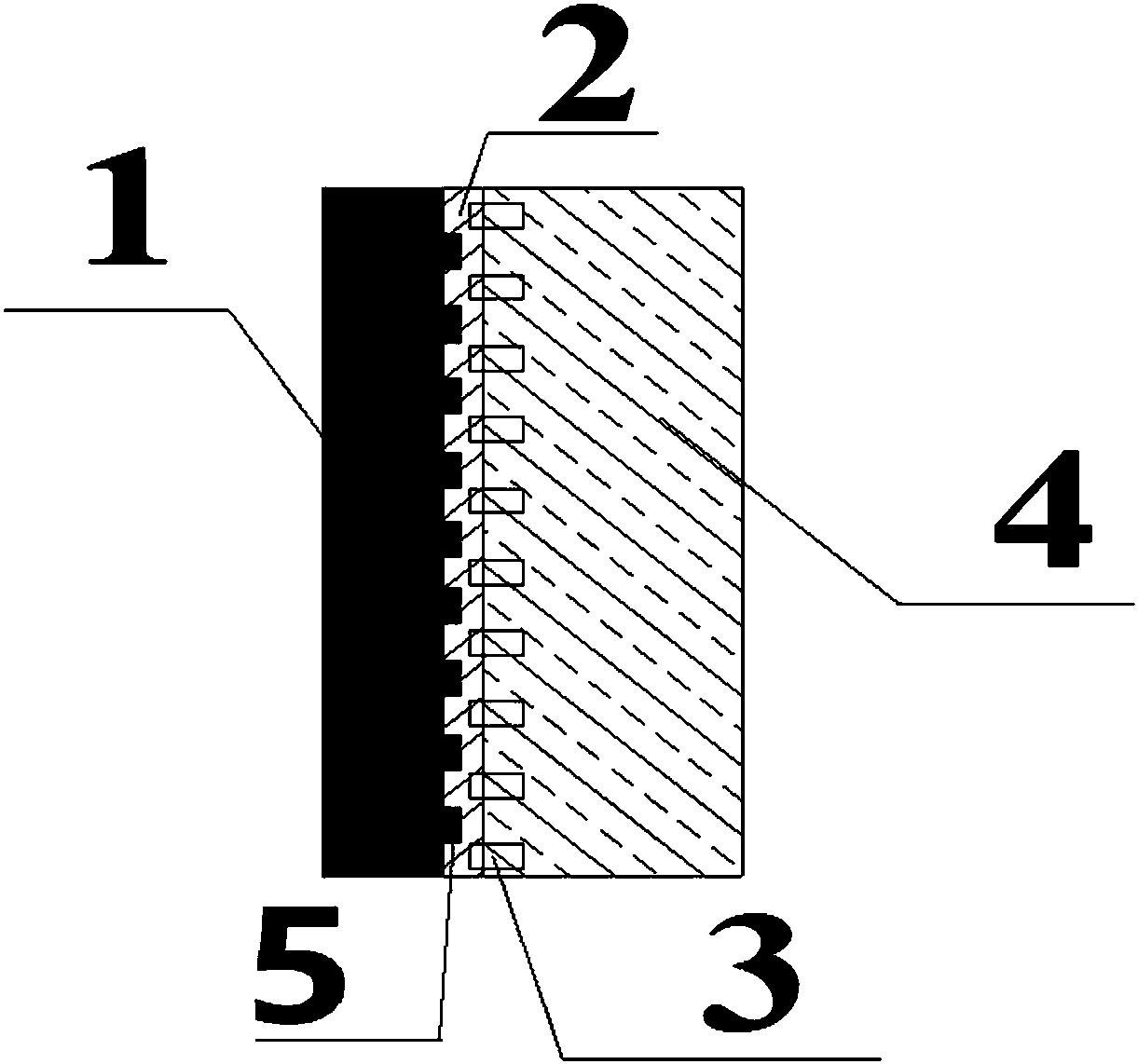

[0032] 1. Preparation of organic bottom layer: mix epoxy resin SM828, curing agent polyamide 650, and toughening agent liquid rubber at room temperature in a mass ratio of 7:2:1 to obtain a light yellow transparent liquid. Coating on one side surface of 100×25×1.6mm steel plate after derusting, coating thickness is 2mm.

[0033] 2. Preparation of fiber reinforcement layer: before the organic bottom layer is solidified, spread a layer of No. 4 alkali-free glass cloth (soaked with fiber impregnating glue) on it. The layer thickness is 0.5 mm.

[0034] 3. Preparation of organic surface layer: After mixing epoxy resin SM828, curing agent polyamide 650, and toughening agent liquid rubber at room temperature in a mass ratio of 7:2:1, a light yellow transparent liquid is obtained. The organic material is coated on the fiber reinforcement layer with a coating thickness of about 1 mm to prepare an adhesive with a total thickness of 3.5 mm.

[0035] 4. Cov...

Embodiment 2

[0037] Experiment No. J2:

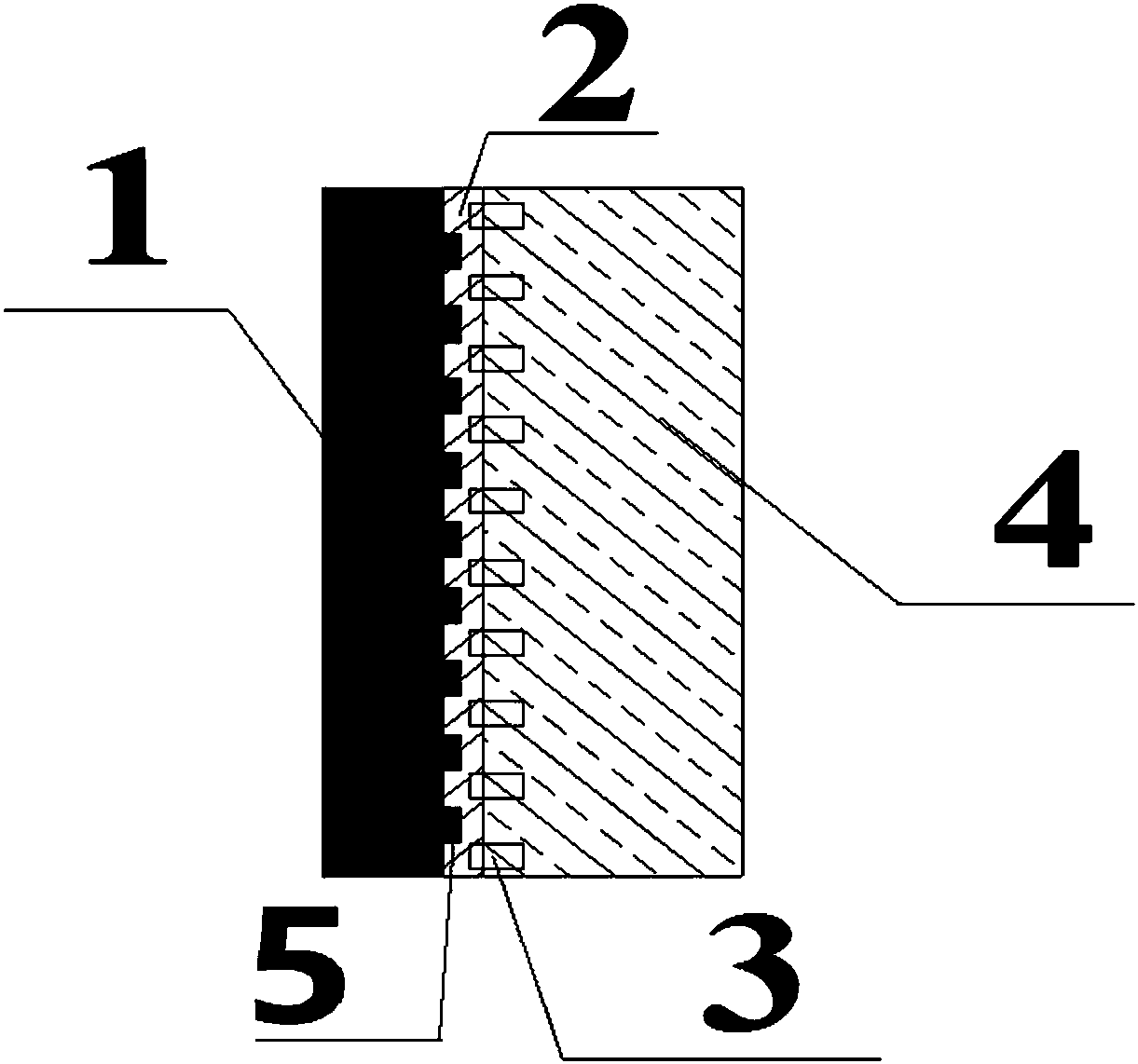

[0038] 1. Preparation of organic bottom layer: Mix epoxy resin SM828, curing agent polyamide 650, and toughening agent liquid rubber at room temperature in a mass ratio of 7:2:1 to obtain a light yellow transparent liquid. Coating on one side surface of 100×25×1.6mm steel plate after derusting, coating thickness is 2mm.

[0039] Vertically and evenly place 3*10 cylindrical fixed structures with a height of 0.5 mm and a diameter of 1 mm on the base layer, and the material is steel. Inserted with basal layer 0.2mm.

[0040] 2. Preparation of the fiber reinforcement layer: before the organic bottom layer is cured, two layers of No. 4 alkali-free glass cloth (soaked with fiber impregnating glue) are laid on it. The layer thickness is 0.8 mm.

[0041] Open evenly on the fiber reinforced layer, 2*4 grooves with a diameter of 2mm running through the fiber reinforced layer.

[0042] 3. Preparation of organic surface layer: After mixing epoxy resin SM828...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com