Use of an adhesive composition based on silylated polymers for cryogenic applications

A silylation, polymer technology, applied in the direction of polyether adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problem of not providing shock-absorbing buffers and absorbing deformation, to prevent harmful the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0181] Several adhesive compositions of the present invention were prepared and tested.

[0182] Use the following products:

[0183] -PS1: XB502(Wacker);

[0184] -PS2: STP-E15(Wacker);

[0185] -PS3: STP-E10(Wacker);

[0186] -PS4: MS S303H (Kaneka);

[0187] -PS5: 1050MM (Momentive);-

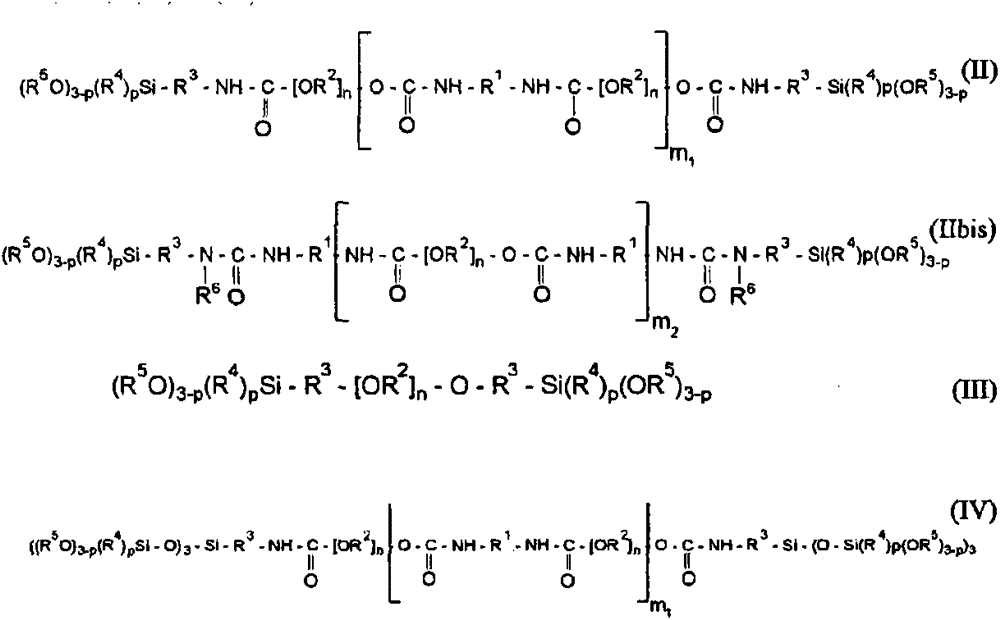

[0188] -PS6: PolymerA described in International Application WO2009 / 106699 (corresponding to the polymer of formula (II) defined above, wherein R 1 stands for isophorone diisocyanate (IPDI);

[0189] - PS7: polymer corresponding to the formula (IIbis) defined above;

[0190] - CM1: Precipitated calcium carbonate with 0.05 μm particle size determination 312 (Solvay);

[0191] - CM2: aluminum hydroxide with 3 μm particle size determination OL104 (Martinwerk);

[0192] -CO1: polyvinyl chloride 373 (Solvay);

[0193] -AO: Antioxidant 1010 (BASF);

[0194] -CH: moisture scavenger XL10 (Wacker);

[0195] -PA: Adhesion promoter GF9(Wacker);

[0196] -Kta1: diazabic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com