Large area metal thin plate curtain wall system

A large-area metal and metal plate technology, applied in the direction of walls, building components, buildings, etc., can solve the problem of surface flatness of metal sheets, insufficient flatness and supporting force in the middle of the plate, affecting the aesthetics and reliability of the overall wall surface. problems, such as widening the scope of use, high construction efficiency, and simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

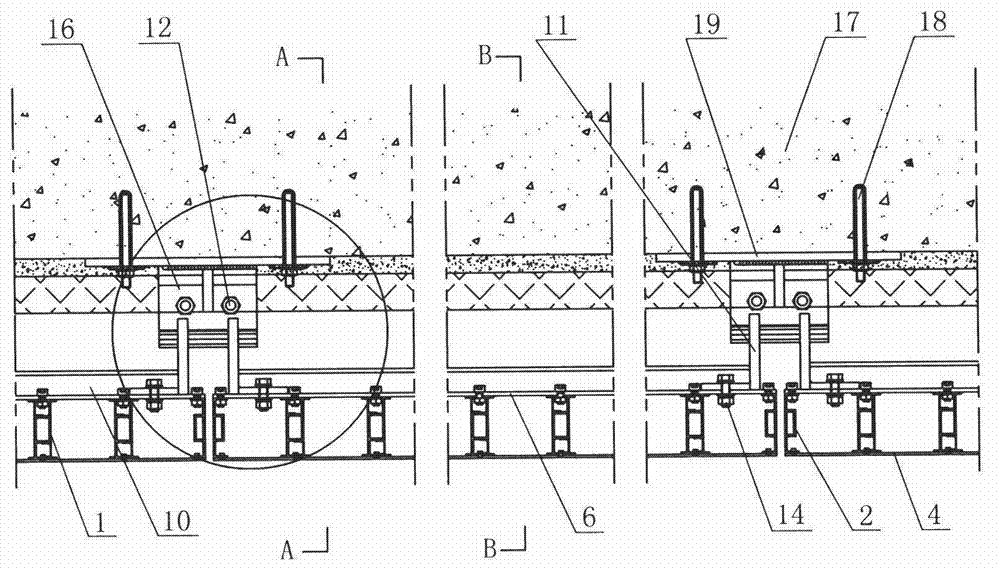

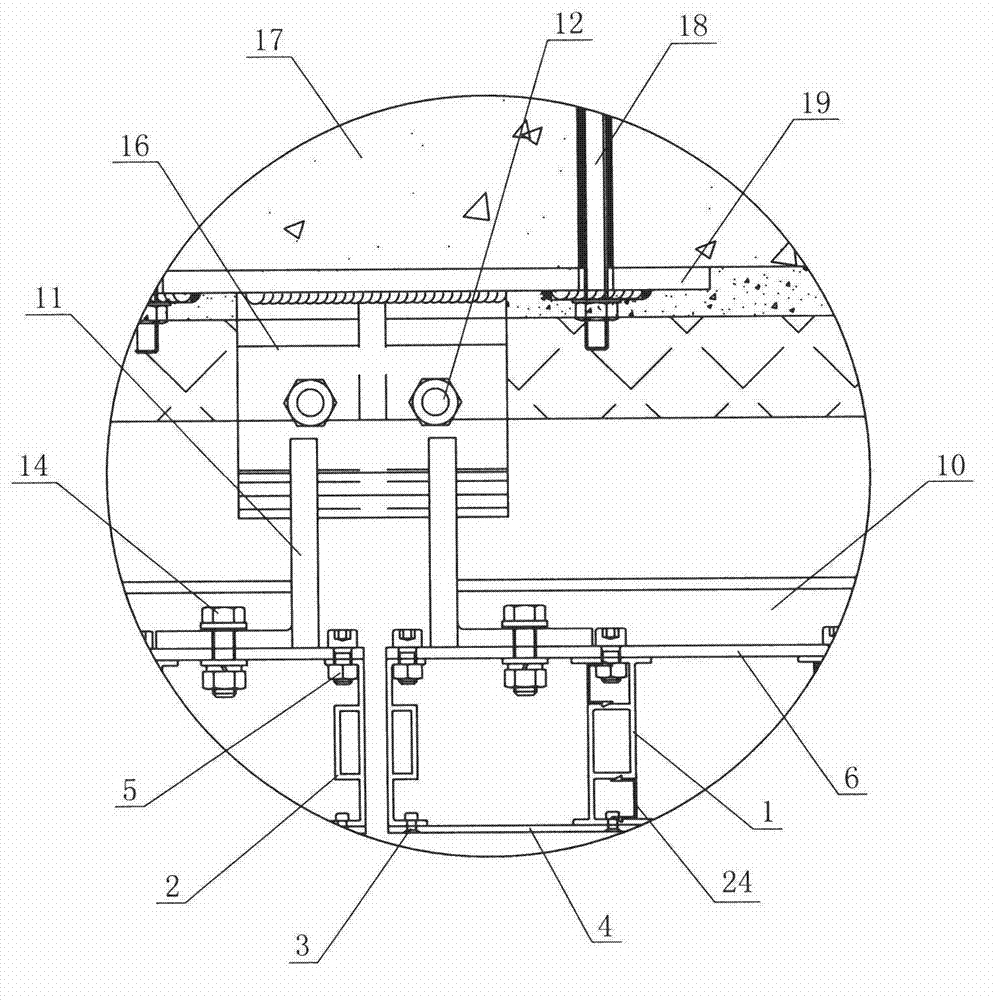

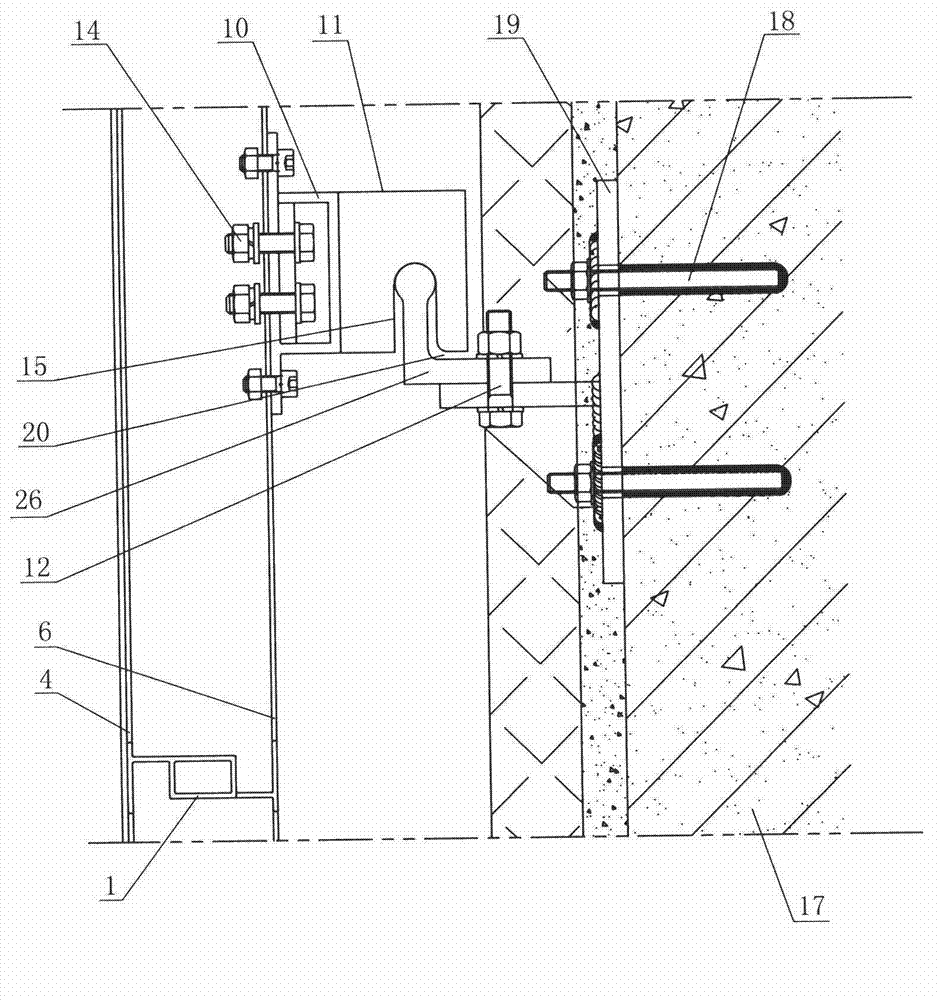

[0033] Embodiment one: see Figure 1-7 As shown, a large-area metal sheet curtain wall system includes a metal plate assembly and a dry-hanging assembly. The support column 1 and the metal side seal support column 2 on both sides of the inner and outer metal plates are composed. One end of each metal vertical support column 1 is fixed to the outer metal plate 4 by a countersunk rivet 3, and the other end is fixed to the outer layer metal plate 4 by a bolt 5. The inner metal plate 6 is fixed, and the distance between the adjacent metal vertical support columns 1 is 100mm; the inner metal plate 6 and the outer metal plate 4 are parallel to the metal vertical support columns 1 respectively A metal side seal support column 2 is provided, and the middle part of the metal side seal support column 2 is provided with a reinforcing rib 7, and the two ends are respectively bent to the corresponding side of the metal plate assembly to form a connecting edge 8, and one end of the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com