Process for preparing oil slurry of lithium ion battery

A lithium-ion battery and preparation process technology, which is applied in the field of preparation of lithium-ion battery oily slurry, can solve the problems of easy gelation of oily slurry, poor adhesion of pole pieces, poor consistency and stability of slurry, etc., and achieve reduction Effect of cross-linking agglomeration and reducing cross-linking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

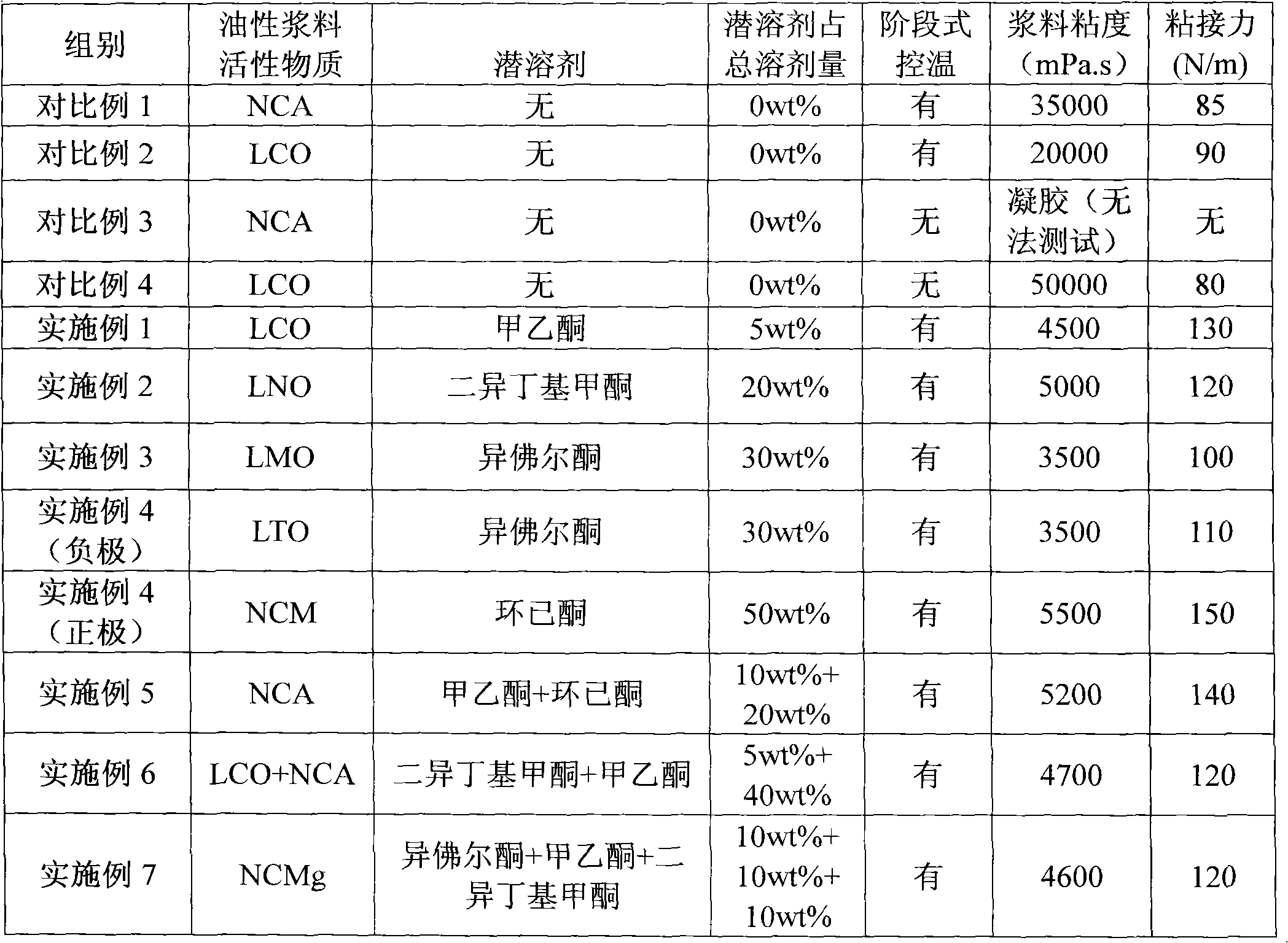

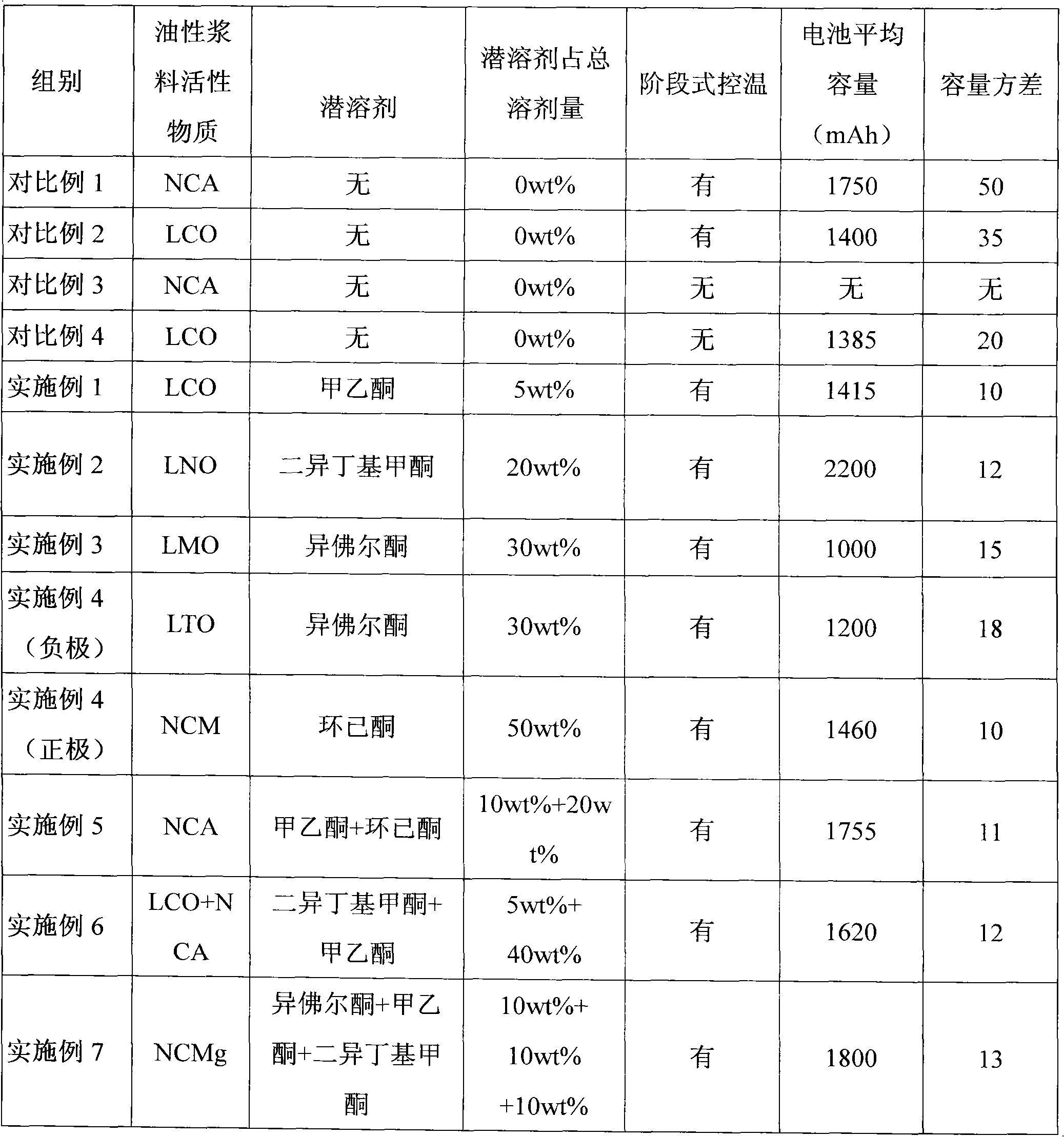

Embodiment 1

[0028] Preparation of positive electrode slurry and positive electrode sheet:

[0029] Lithium cobaltate (LCO) is used as the positive electrode active material, and the positive electrode slurry containing the active material is formulated according to the formula. The solid content of the slurry includes 90wt% of the positive electrode active material, 5wt% of polyvinylidene fluoride (PVDF ) (bonding agent), 5wt% conductive carbon (conductive agent). The slurry uses NMP as a true solvent, the true solvent accounts for 95wt% of the total solvent (i.e. the sum of the latent solvent and the true solvent), the latent solvent is methyl ethyl ketone, the latent solvent accounts for 5wt% of the total solvent, and the solid content of the slurry is 75%. , first put the true solvent and polyvinylidene fluoride (PVDF) into the stirrer, stir at 50±1°C, and then add conductive carbon powder to stir and disperse after the dissolution is complete. At this stage, the slurry temperature is ...

Embodiment 2

[0035] The difference from Example 1 is that lithium nickelate (LNO) is used as the positive electrode active material, the latent solvent is diisobutyl ketone, and the latent solution accounts for 20 wt% of the total solvent.

[0036] The preparation process of the slurry is as follows: first put N-methylpyrrolidone and polyvinylidene fluoride (PVDF) into the stirrer, stir at 45±1°C, and then add conductive carbon powder to stir and disperse after the dissolution is complete. At this stage, the temperature of the slurry is controlled at 45±1°C; after dispersing for 2 hours, lower the temperature of the slurry to 25±1°C, then add the latent solvent diisobutyl ketone, stir for 1.5 hours, and control the temperature at 25±1°C; finally add The active material lithium nickelate (LNO) was stirred for 3 hours to make the final slurry, and the temperature was controlled at 25±1°C.

[0037] Others are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0039] The difference from Example 1 is that lithium manganate (LMO) is used as the positive electrode active material, the latent solvent is isophorone, and the latent solution accounts for 30 wt% of the total solvent.

[0040] The preparation process of the slurry is as follows: first put N-methylpyrrolidone and polyvinylidene fluoride (PVDF) into the stirrer, stir at 54±1°C, and then add conductive carbon powder to stir and disperse after the dissolution is complete. At this stage, the slurry temperature is controlled at 54±1°C; after 4 hours of dispersion, the slurry temperature is lowered to 21±1°C, and then the latent solvent isophorone is added, stirred for 1.5 hours, and the temperature is controlled at 21±1°C; finally added The active material lithium manganate (LMO) was stirred for 4 hours to make the final slurry, and the temperature was controlled at 21±1°C.

[0041] Others are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com