Method and device for the production of form parts

A molded part, mold-carrying technique for the manufacture of molded parts made of multi-component reactive plastics, especially polyurethane, with a high degree of simplicity and design optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

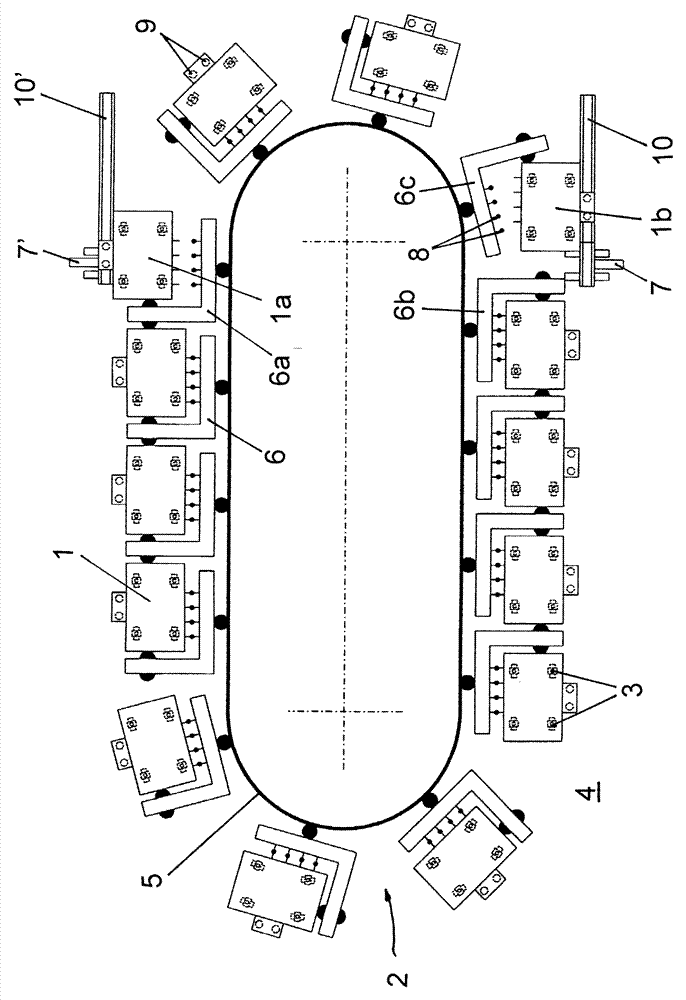

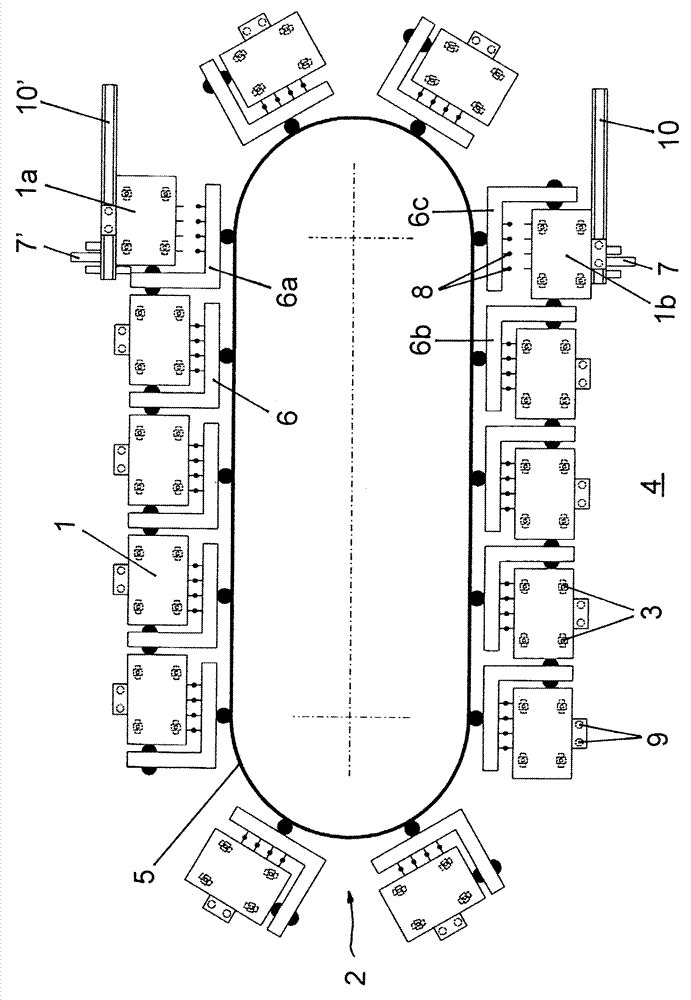

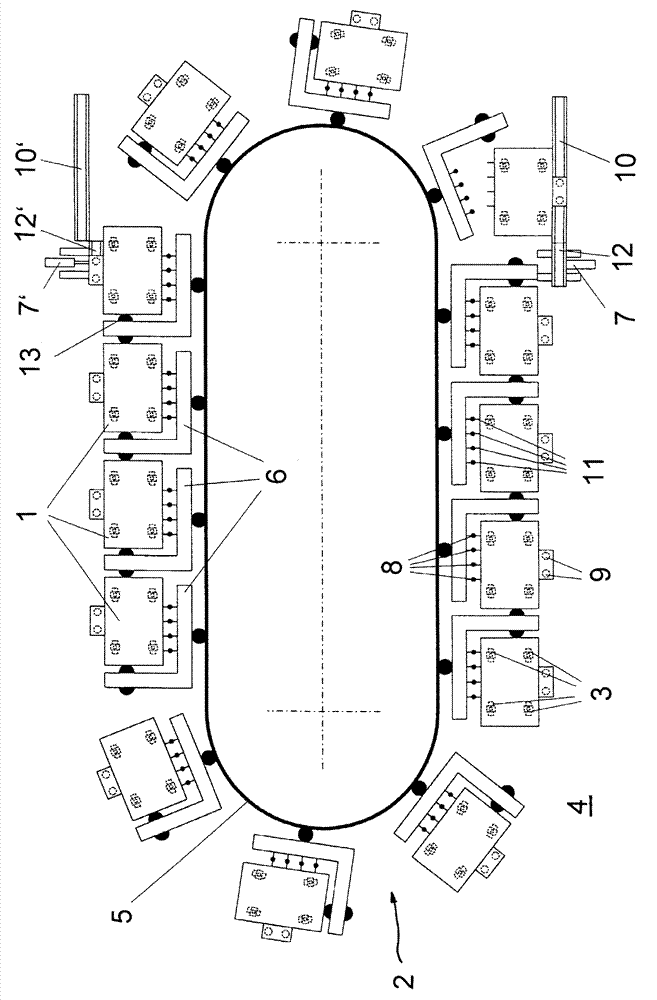

[0065] exist figure 1 Production line 2 is schematically shown in . It comprises a conveyor element 5 (circling chain), which is here designed as an oval conveyor belt. A supply trolley 6 is fastened to the surrounding chain 5 . The supply trolley 6 is designed such that the mold trolley 1 is detachably coupled thereto; the molds for producing the molded parts are located on the mold trolley 1 .

[0066] The supply lines of the supply cart 6 are connected to corresponding lines 11 of the mold carrier 1 via coupling means 8 in the form of quick couplings.

[0067] The mold halves can be raised and lowered or oscillated depending on the application. The molds are preferably opened and closed via fixed slides (not shown), beside which the mold carrier 1 is driven. The slide then moves a stop at the mold (which is connected to a system of levers). Each mold half can then be moved / swiveled about the pivotable support via this lever system.

[0068] The mold carrier 1 is accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com