Guide bar assembly for a warp knitting machine

A warp knitting machine and bar technology are applied in the field of bar devices, which can solve the problems of inability to accurately manufacture, manufacture tolerances, etc., and achieve the effects of simple structure, simplified maintenance, and low risk of vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

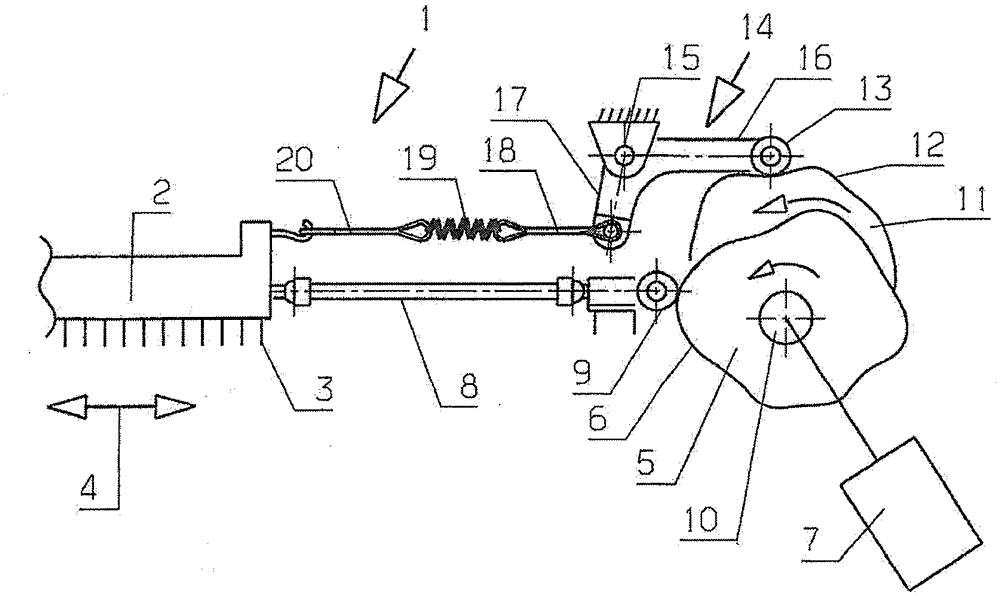

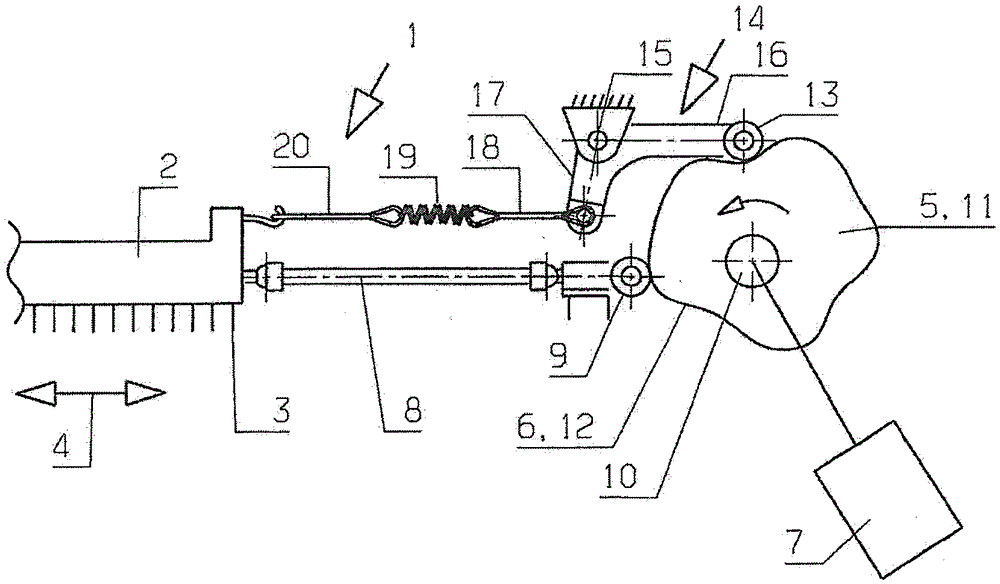

[0023] According to the diagram 1 The bar device has bars that can also be called yarn guide bars 2 . in the comb 2 Several yarn guides are fixed at the 3 , the thread guide is designed, for example, as an eye needle or a thread guide.

[0024] During operation, as shown by the double arrow 4 The bars are driven back and forth as shown. the double arrow 4 The direction parallel to the longitudinal elongation of the bar is shown. In many cases, the bar 2 The movement is also performed perpendicular to the drawing plane during the looping process. However, this is not explained further in the current run.

[0025] The bar device 1 With traverse drive. The traverse drive device has a first peripheral surface 6 Jacquard elements in the form of jacquard discs 5 . the jacquard element 5 by driving the motor 7 to rotate. Instead of the jacquard disc, a jacquard chain can also be used.

[0026] Jacquard tappet 8 with rollers 9 ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com