Mobile bearing press

A press-fitting machine and bearing technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of uncontrollable manual knocking force, unusable assembly line, high requirements for fixture trolley, etc., to reduce engineering defects, The effect of smooth press-fitting process and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

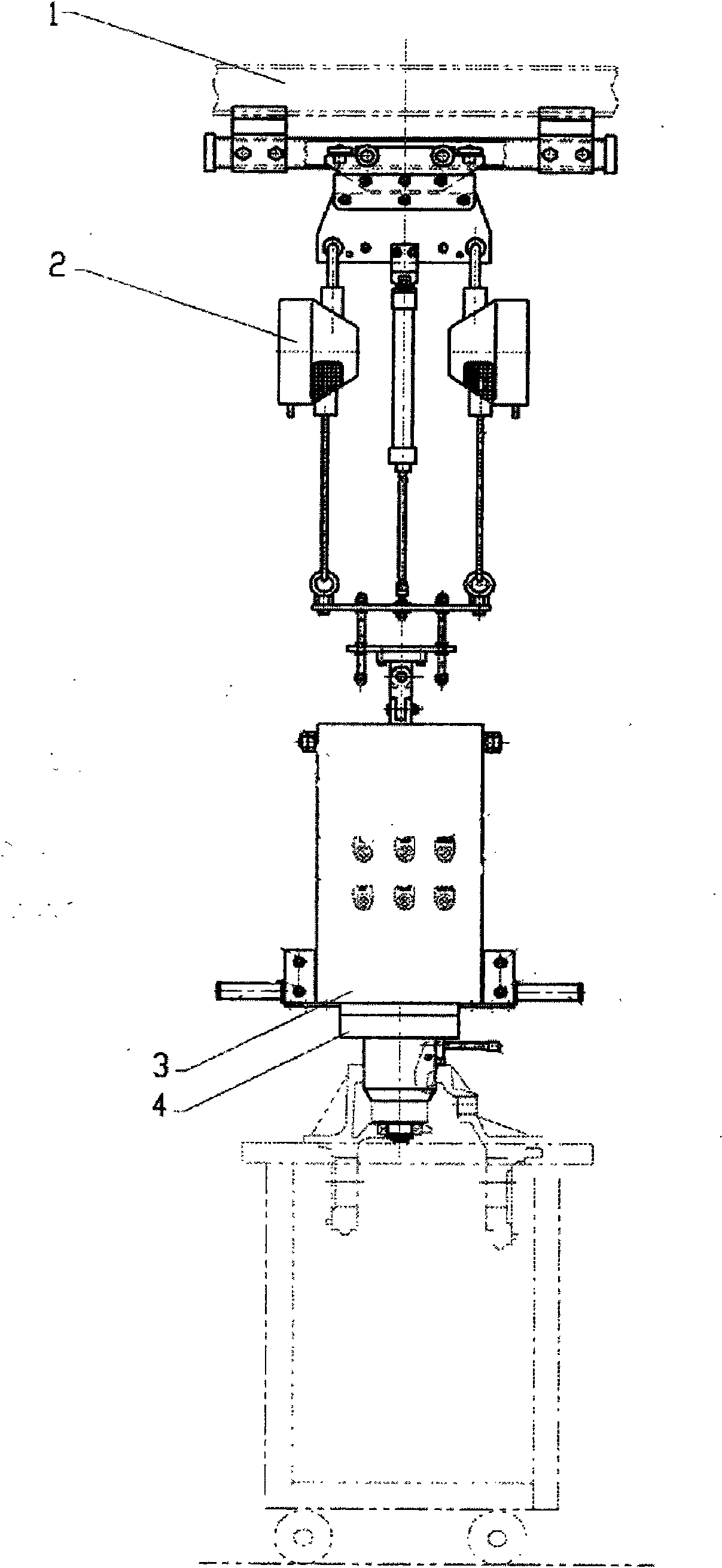

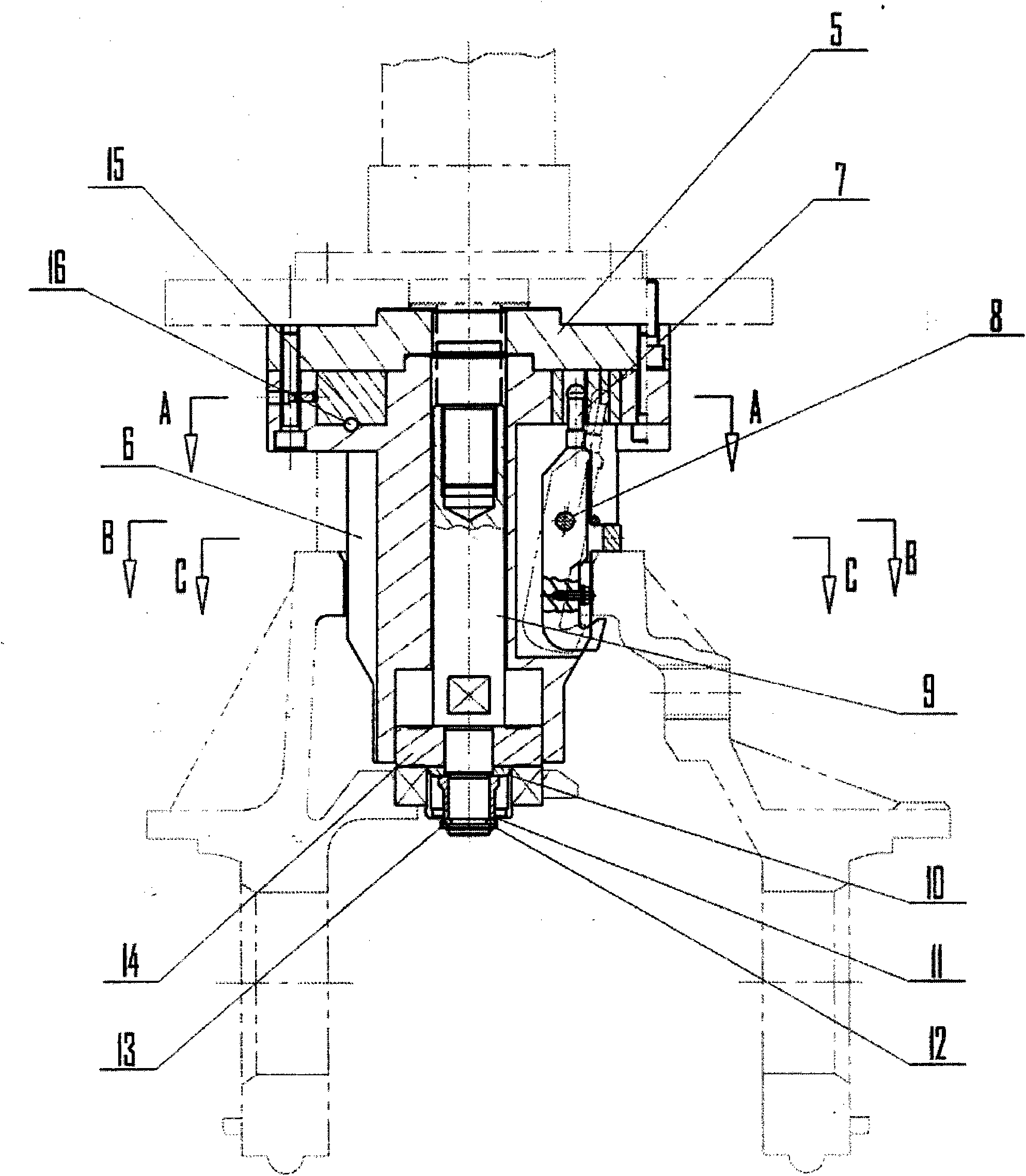

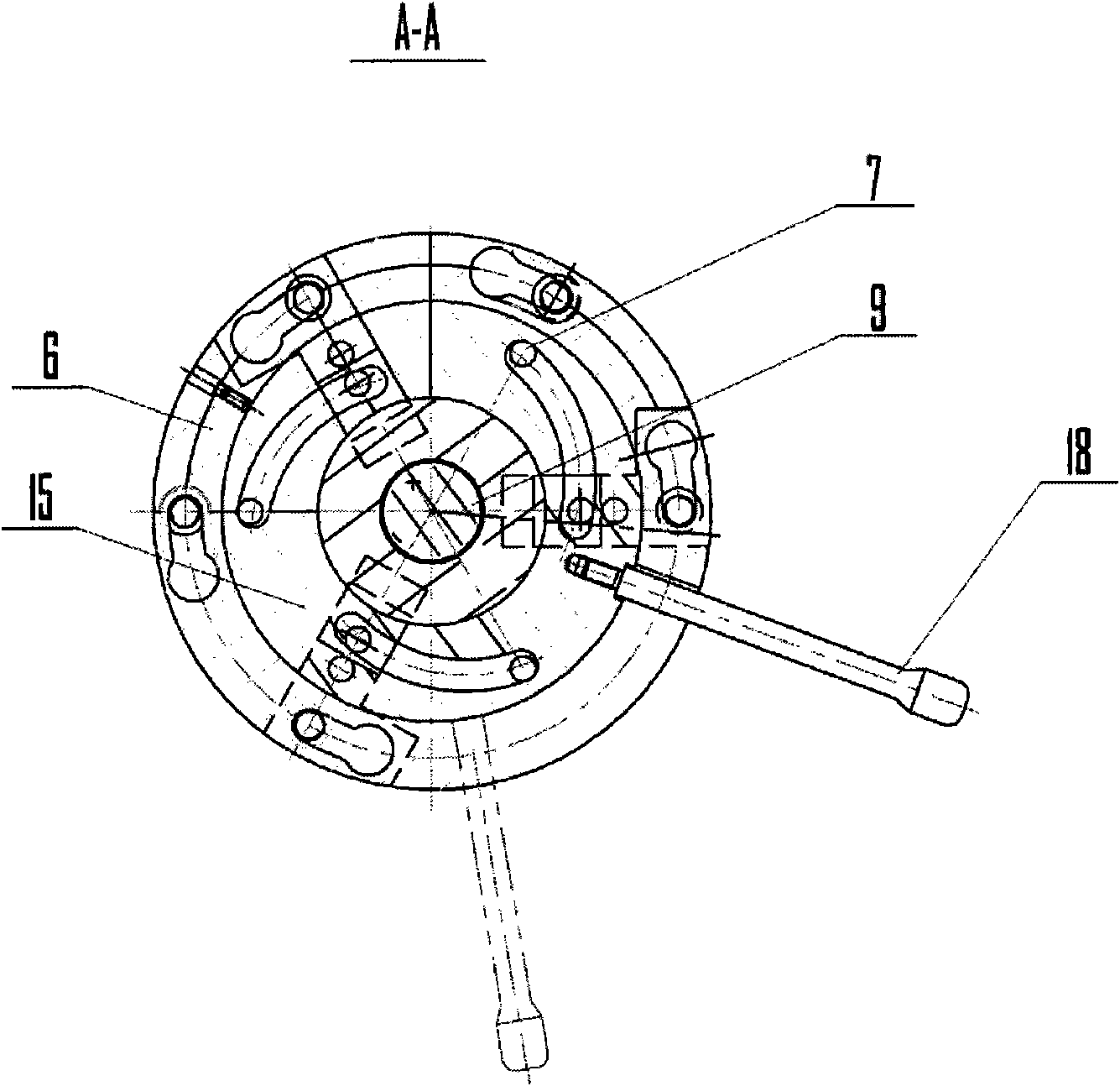

[0018] Such as figure 1 , Figure 6 as shown, figure 1 The dotted line part is the assembly line fixture trolley and the workpiece, Figure 6 The dotted line part is the pneumatic press 3. Such as figure 1 As shown, the pneumatic press 3 is installed on the guide rail 1 through the suspension part 2, and the reaction bar mechanism 4 is connected with the pneumatic press 2.

[0019] Such as figure 1 , Figure 6 As shown, the structure between the pneumatic press 3 and the suspension part 2 is a suspended movable structure. The operation box includes a frame body, a gas-hydraulic pressurized cylinder 24, a hydraulic pressure control, and an electrical control part. Lights, cylinder up and down buttons, left and right indicator lights, booster cylinder up and down indicator lights, booster cylinder up and down buttons, left and right handles; because the outer ring of the bearing needs to be press-fitted and the axle reduction is an interference fit, the pressure needs 20-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com