Workpiece inspection device

A technology for inspection devices and workpieces, which is used in measuring devices, material analysis by optical means, instruments, etc., and can solve the problems that the results do not reach the expected accuracy and cannot be adapted to high-precision detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

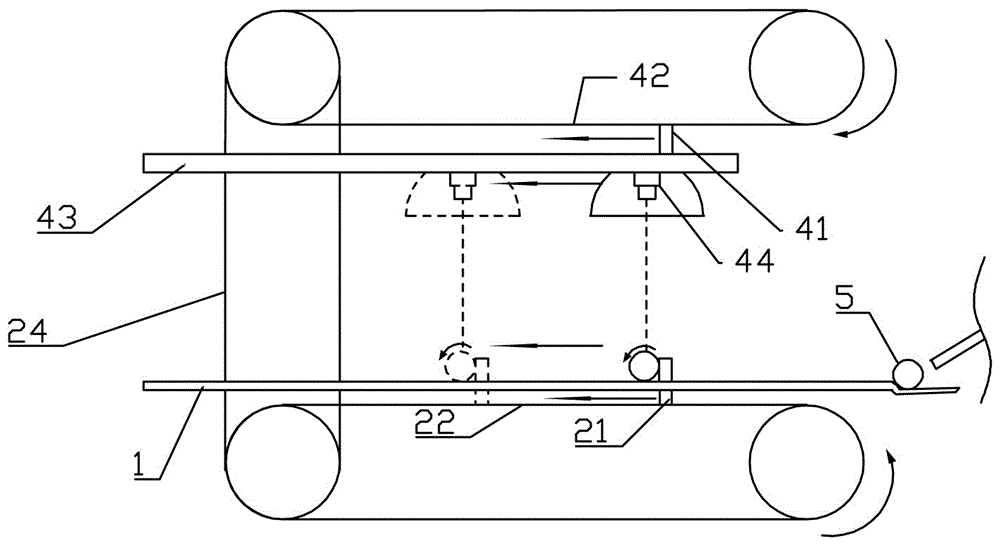

[0022] Embodiment 1: as figure 1 The workpiece inspection device shown includes a frame, a flat plate 1, a pusher for pushing a cylindrical workpiece 5 to roll on the flat plate, a camera above the flat plate 1, and a camera transporter for pushing the camera. The flat plate 1 is inclined. The push piece includes a workpiece conveyor belt 22 and a push plate 21, the flat plate 1 has a long hole, and the push plate 21 is located below the flat plate 1 and extends into the long hole;

[0023] The camera transport part comprises a track 43 and a camera conveyor belt 42 fixed on the frame, the camera 44 is slidably connected to the track 43, the track 43 is fixed on the frame, a return spring is provided between the camera 44 and the track 43, and the camera conveyor belt 42 A camera push plate 41 is fixed, and the camera push plate 41 stretches between the tracks to resist the camera 44, and the camera push plate 41 and the push plate 21 move in the same direction and at the sam...

Embodiment 2

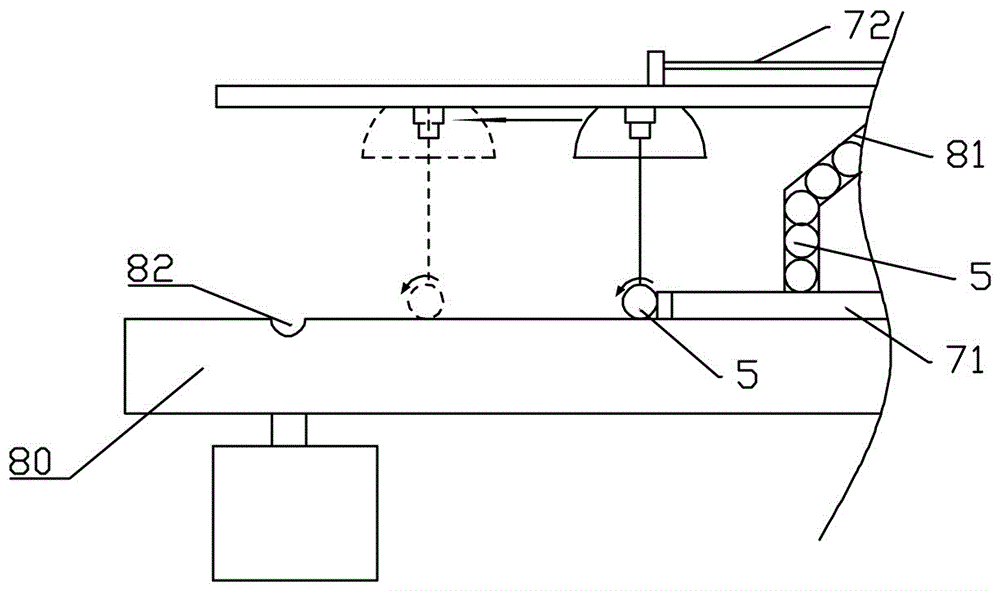

[0025] Embodiment 2: as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that the camera transport part is connected with a camera pushing stepping motor, and the camera pushing stepping motor has a camera push rod 72, and the pushing part is connected with a workpiece pushing stepping motor, and the workpiece pushing stepping motor A workpiece push rod 71 is provided. The flat plate 80 is provided with a feed pipe 81 and a discharge chute 82 .

Embodiment 3

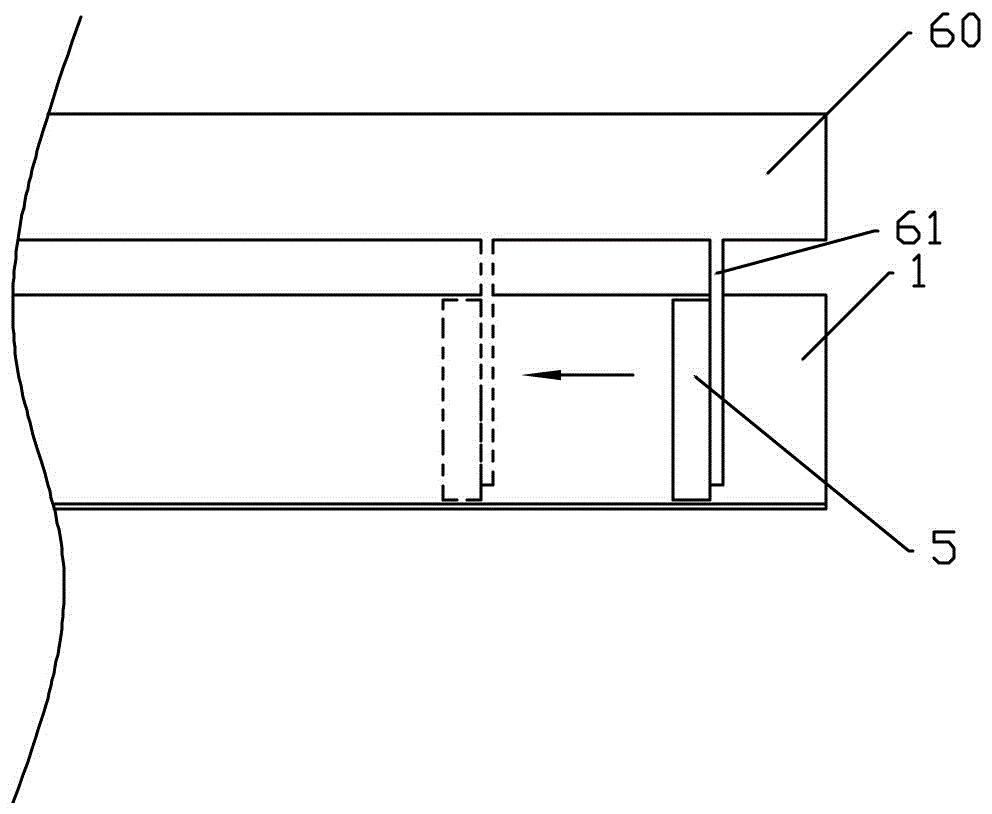

[0026] Embodiment 3: as image 3 As shown, the difference between Embodiment 3 and Embodiment 2 is that the push piece includes a workpiece conveyor belt 60 and a push plate 61, the push plate 61 is fixed on the workpiece conveyor belt, and the push plate 61 is located on one side of the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com