Industrial double-beam area divided type 3D printer

A 3D printer, double beam technology, applied in 3D object support structures, manufacturing tools, additive processing, etc., can solve the problems of limited printing space, slow molding speed, and inability to print in multiple areas at the same time, to achieve rich functions and prevent leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

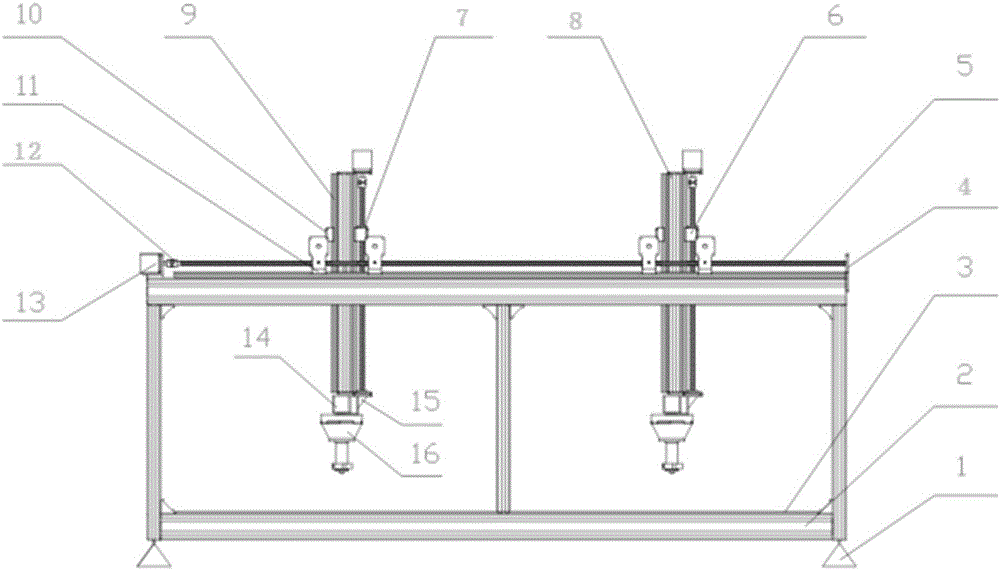

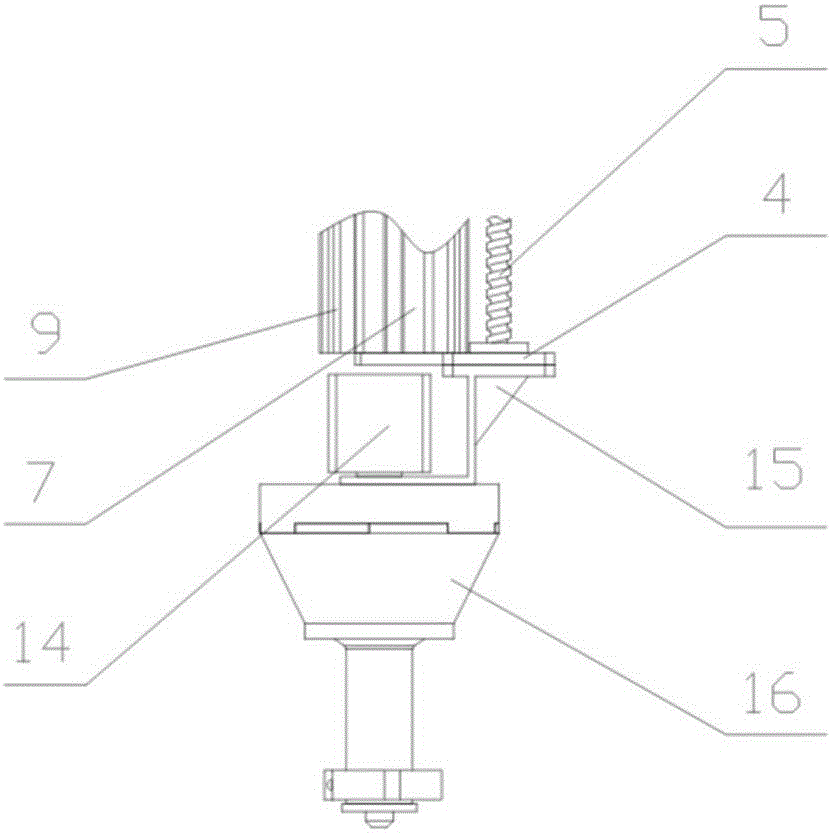

[0027] An industrial double-beam sub-regional 3D printer, mainly composed of a frame 2, a printing platform 3, a movement mechanism and a nozzle mechanism;

[0028] The frame 2 is a cube, the middle part is provided with a support beam, and the printing platform 3 is horizontally and fixedly installed on the bottom surface of the frame 2; in order to ensure that the bottom of the horizontal frame 2 of the printing platform is supported horizontally on the ground by several foot cups 1 during work;

[0029] The specific structure of the described motion mechanism is as follows:

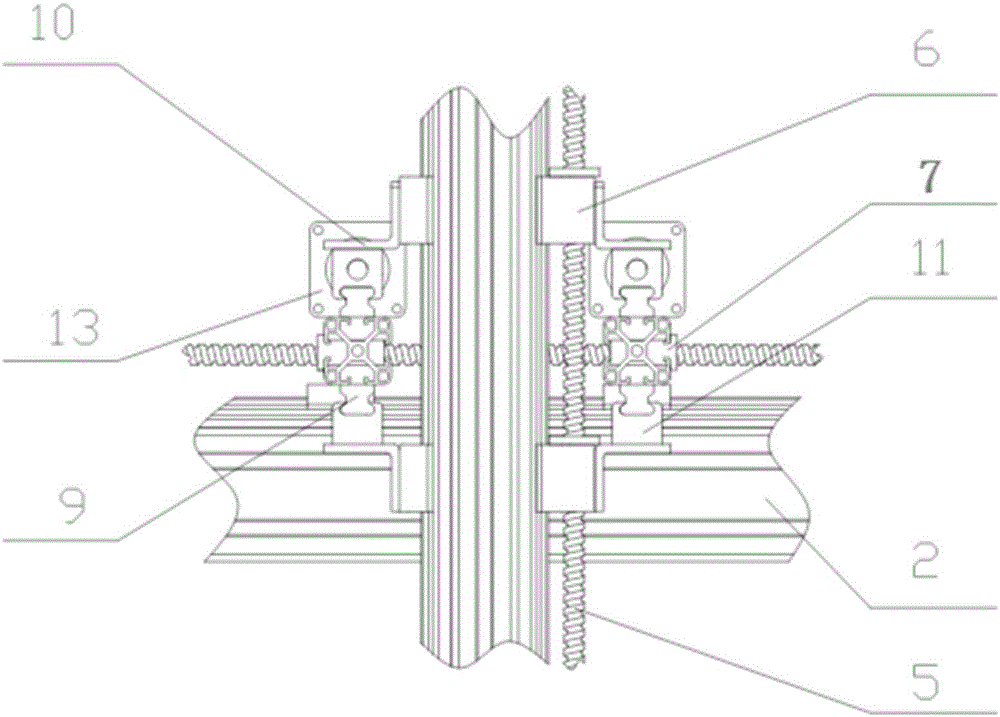

[0030] Linear guide rails 9 are respectively fixed on both sides of the top of the frame 2 in the X-axis direction, and the ball screw 5 is fixed above the linear guide rail 9 through the ball screw support seat 4; in cooperation with the ball screw 5, two groups of Double beam mechanism, a certain distance is left between two groups of double beam mechanisms, and the double beam mechanism is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com