Compressing apparatus and control method for multi-cylinder synchronously pressurizing

A technology of pressing device and cylinder seat, which is applied in the direction of fluid pressure actuating device, servo motor, mechanical equipment, etc., can solve problems such as multi-cylinder imbalance, and achieve the effect of uniform force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

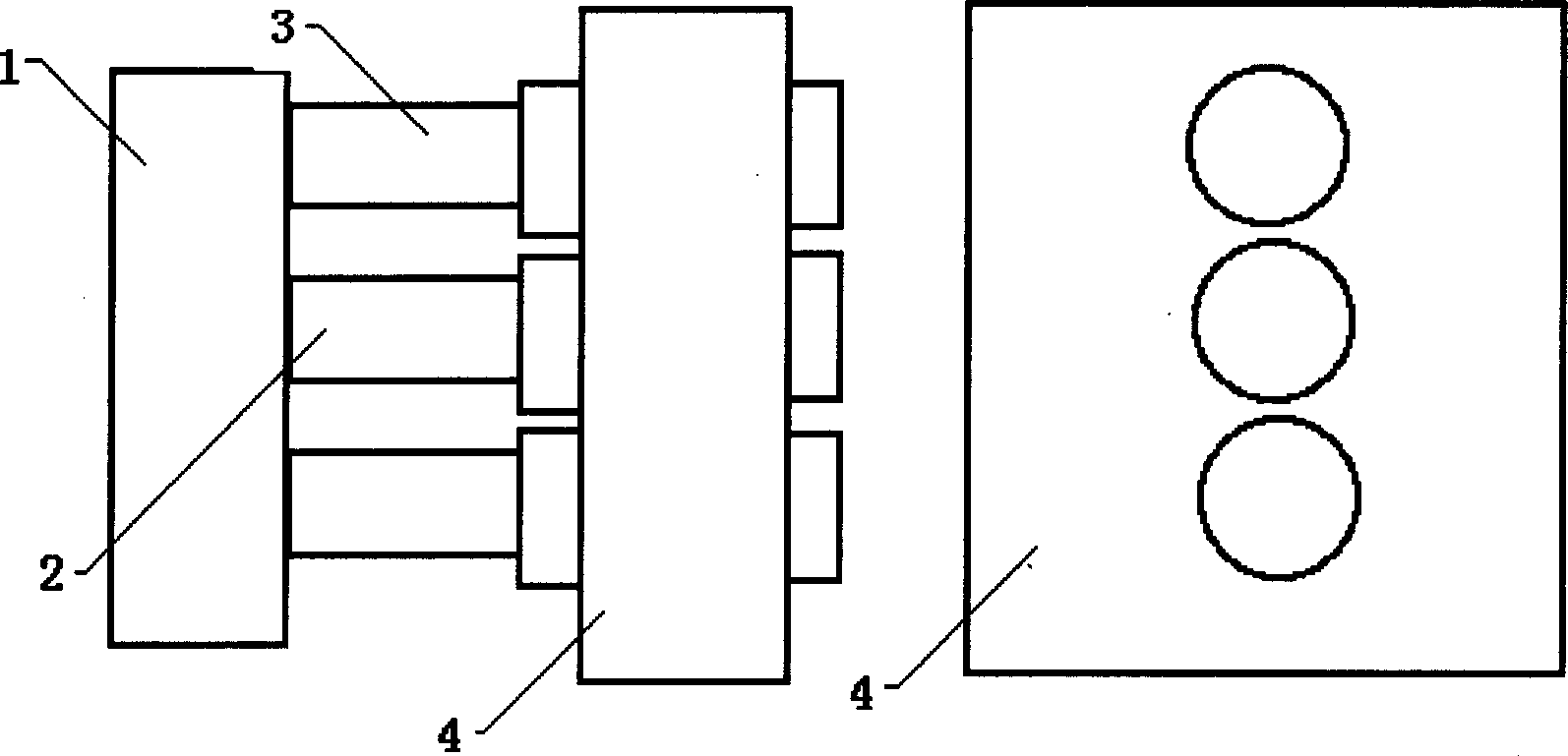

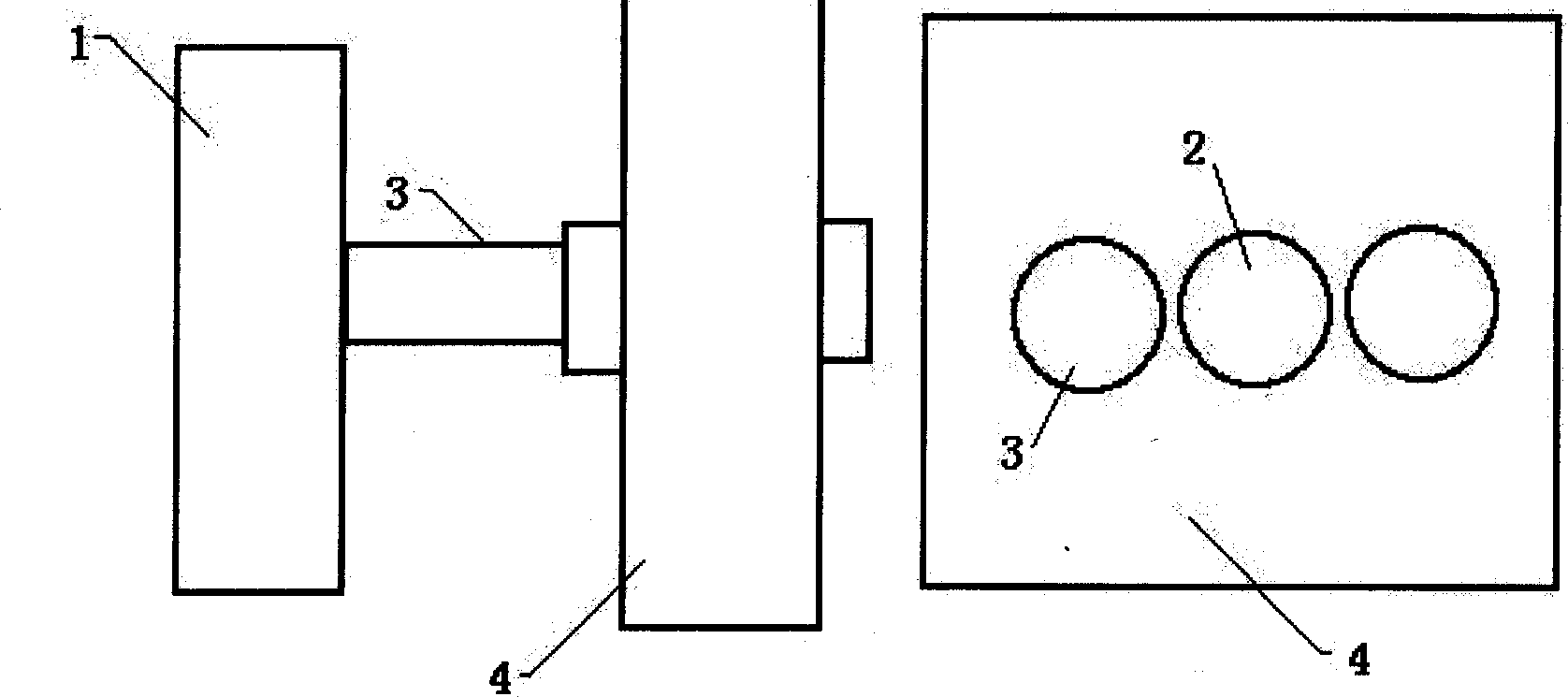

[0021] Example 1: In figure 1 , figure 2 Among them, the multi-cylinder synchronous pressurization (compression) system includes a cylinder base 1, a main hydraulic cylinder or main cylinder 2, at least two auxiliary hydraulic cylinders or auxiliary cylinders 3; the main hydraulic cylinder or main cylinder 2 is installed on the cylinder base plate frame 4, the auxiliary hydraulic cylinder or auxiliary cylinder 3 is distributed on the edge of the cylinder base 1 and the plate frame 4. The main hydraulic cylinder or main cylinder 2 and two auxiliary hydraulic cylinders or auxiliary cylinders 3 are installed vertically in a row, or as figure 2 As shown, the main hydraulic cylinder or main cylinder 2 and two auxiliary hydraulic cylinders or auxiliary cylinders 3 are installed horizontally in a row.

Embodiment 2

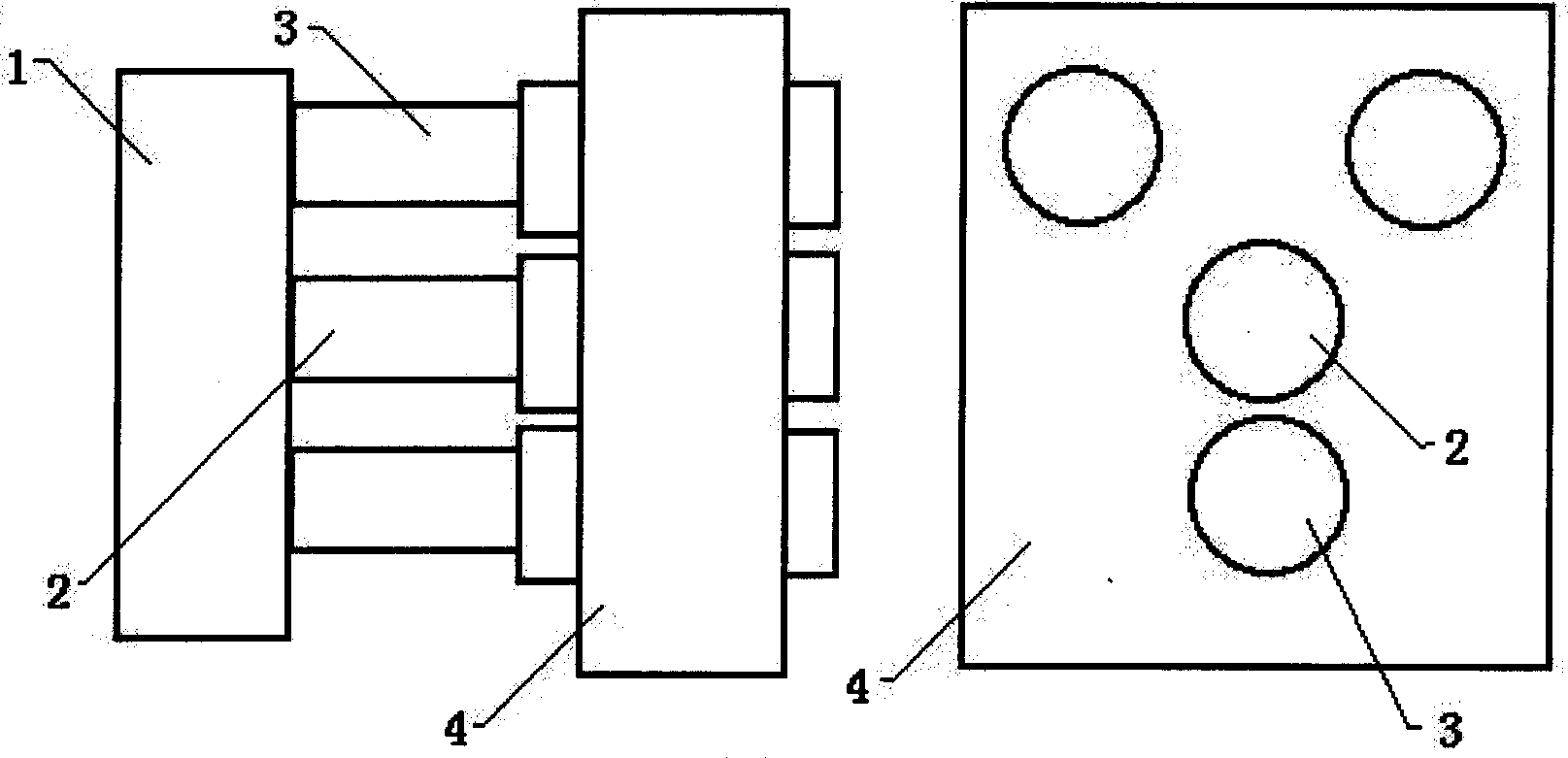

[0022] Example 2: In image 3 , in Figure 4, the multi-cylinder synchronous pressurization (compression) system includes a cylinder base 1, a main hydraulic cylinder or main cylinder 2, three auxiliary hydraulic cylinders or auxiliary cylinders 3; the main hydraulic cylinder or main cylinder 2 is installed on the cylinder base In the central part of the plate frame 4, the auxiliary hydraulic cylinder or the auxiliary air cylinder 3 are distributed on the edge of the cylinder base 1 and the plate frame 4. Master hydraulic cylinder or main cylinder 2 and three auxiliary hydraulic cylinders or auxiliary cylinder 3 are installed in word arrangement or main hydraulic cylinder or main cylinder 2 and three auxiliary hydraulic cylinders or auxiliary cylinder 3 are arranged in reverse order.

Embodiment 3

[0023] Embodiment 3: in Fig. 5, Figure 6 Among them, the multi-cylinder synchronous pressurization (compression) system includes a cylinder base 1, a main hydraulic cylinder or main cylinder 2, four auxiliary hydraulic cylinders or auxiliary air cylinders 3; the main hydraulic cylinder or main air cylinder 2 is installed on the cylinder base plate frame 4 The central part of the cylinder, the auxiliary liquid cylinder or the auxiliary cylinder 3 are distributed on the edge of the cylinder base 1 and the plate frame 4. Four auxiliary hydraulic cylinders or auxiliary cylinders 3 are arranged and installed on the four corners of the cylinder base plate frame 4 or four auxiliary hydraulic cylinders or auxiliary cylinders 3 are installed on the edge middle part of the cylinder base plate frame 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com