Laser-cutting automatic loading and unloading manipulator

A technology of automatic loading and unloading and laser cutting, which is applied in the direction of manipulators, laser welding equipment, chucks, etc., and can solve problems affecting processing speed, automatic removal, and cylinder jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

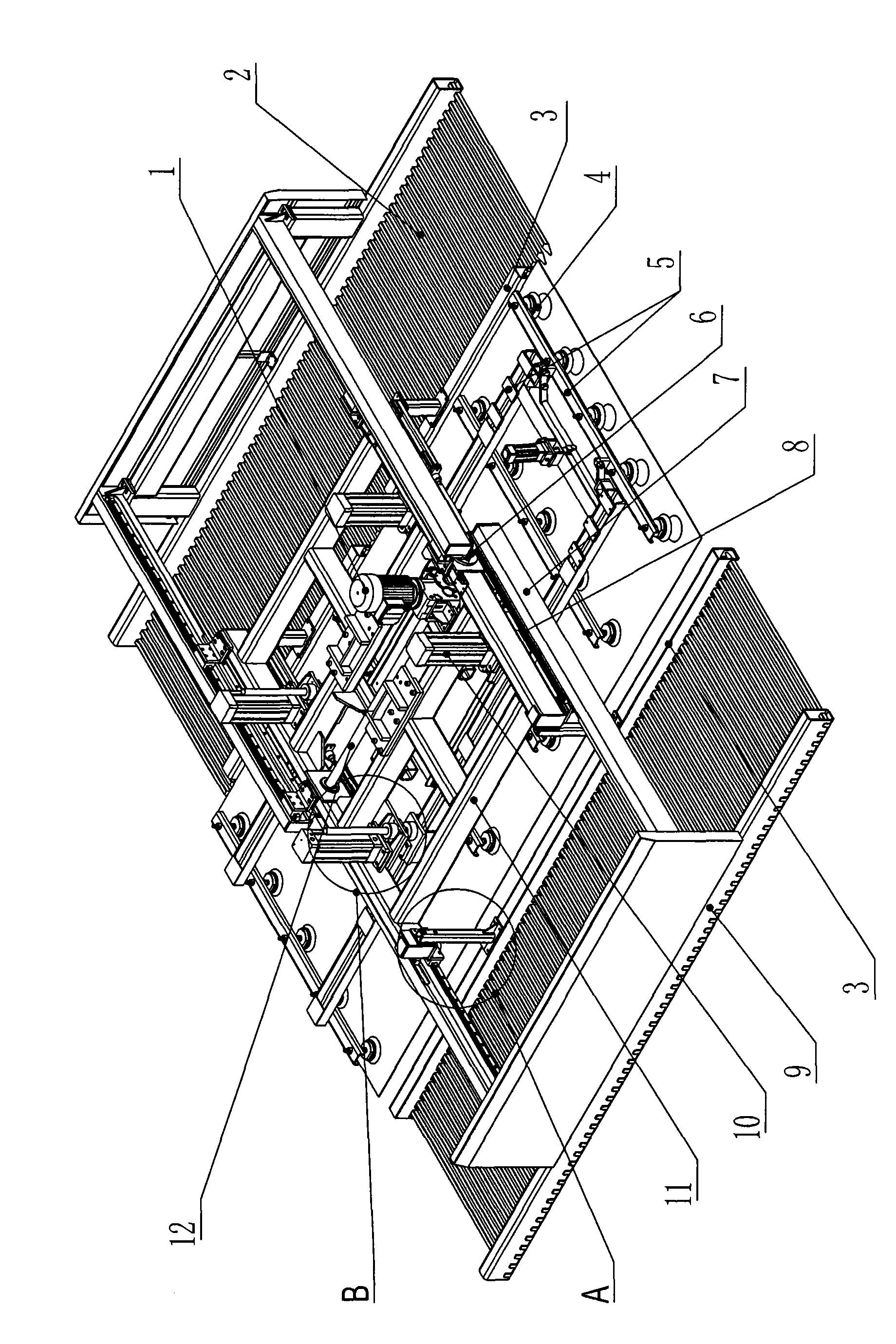

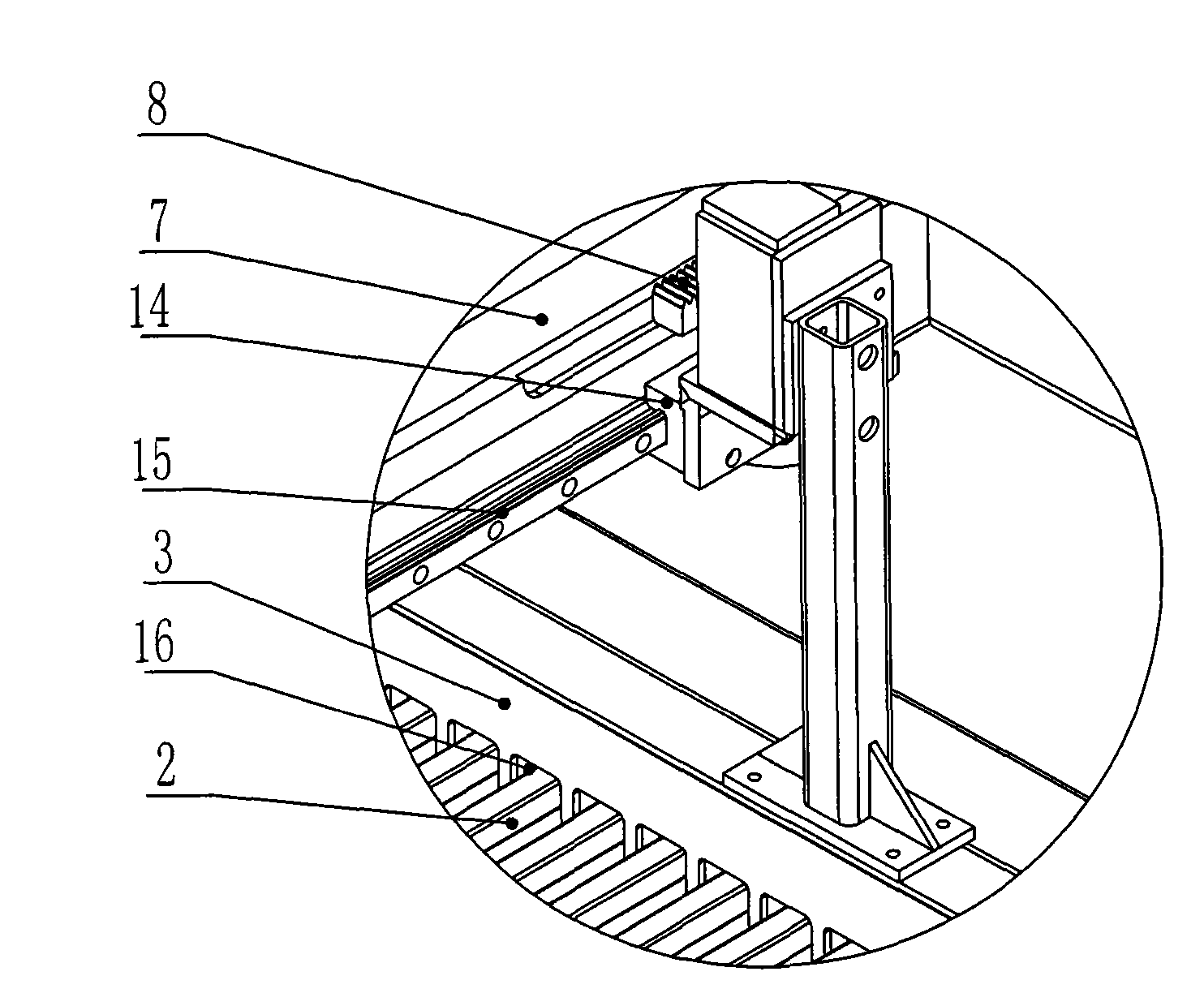

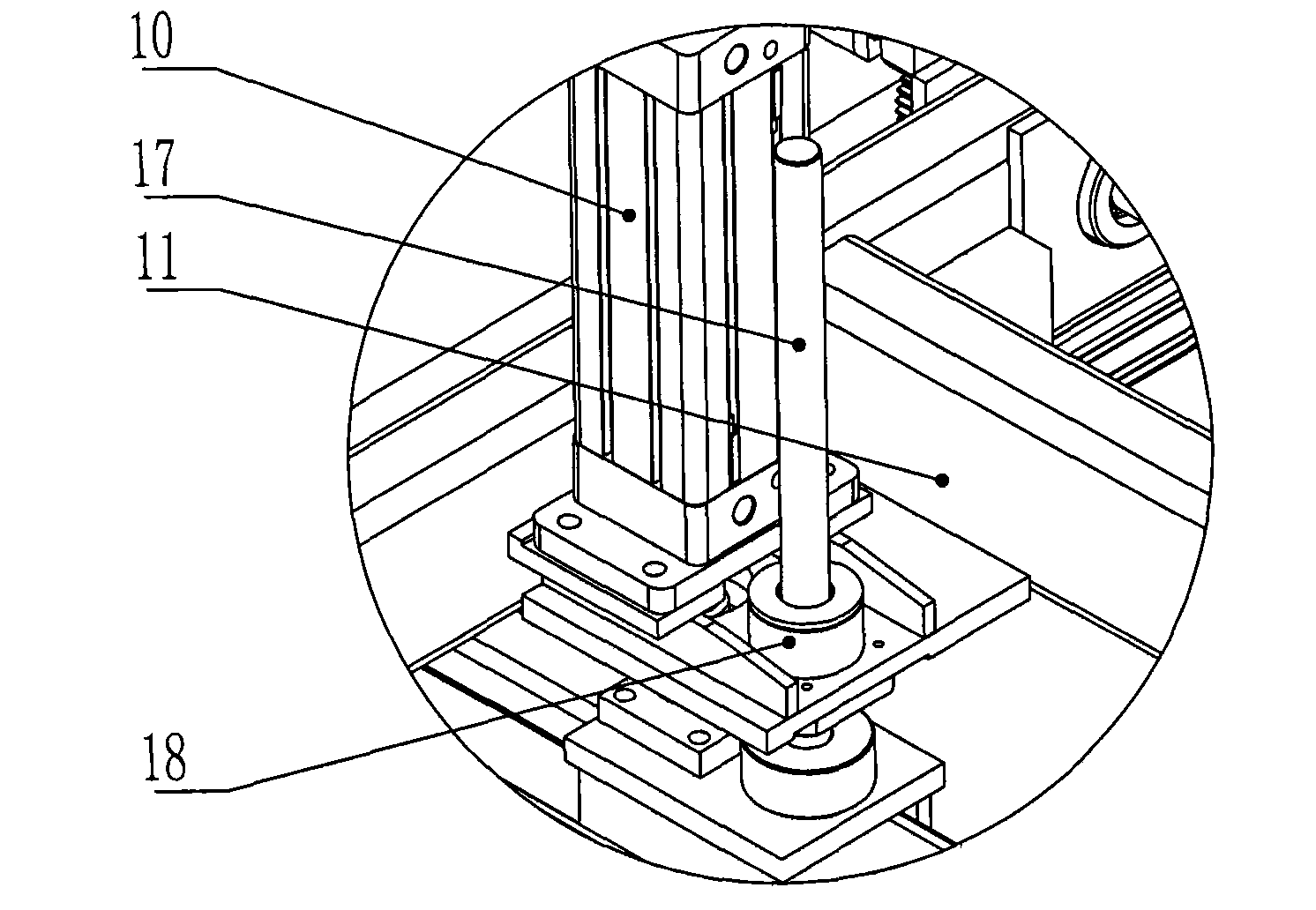

[0020] Such as Figure 1-5 As shown, it is a laser cutting automatic loading and unloading manipulator, including a grid-shaped suction cup frame 5 welded by channel steel. There are several suction cups 4 on the lower side of the suction cup frame 5. According to the size of the plate to be processed, the suction cups 4 can be as follows: Figure 6 As shown, it is divided into three areas, corresponding to different sizes of sheet metal, and the work in different areas can be realized through the air valve. A support frame 11 that can be connected with the feeding mechanism of the machine tool is provided above the suction cup frame 5. The support frame 11 is provided with a drive The lifting mechanism of the suction cup frame 5 lifting movement; the support frame 11 is also provided with a geared motor 1, the middle part of the transmission shaft 12 is connected with the geared motor 1, and the transmission shaft 12 is installed on the support frame 11 through the bearing, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com