Crane for aerated concrete production

A technology of air-entrained concrete and frame, which is applied in the direction of load block, load suspension components, transportation and packaging, etc. It can solve problems such as waste of working time, impact on product quality, unstable movement, etc., achieve compact structure and reduce working time , the effect of increased automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

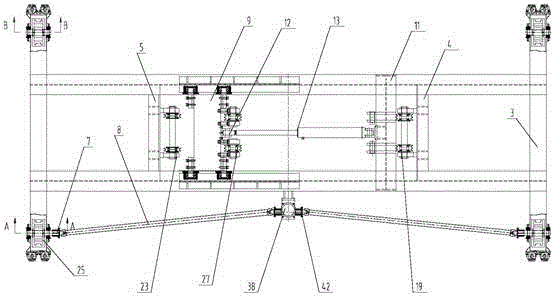

[0016] Embodiment 1: As shown in Figure 1, a crane for aerated concrete production, including a vehicle frame 1, a mounting beam 4, a mounting beam 2 5, a half-coupling 7, a half-coupling 42, and a universal Axle 8, steel wire rope 14, oil cylinder 13, dolly 9, motor 10, speed reducer 38, driving wheel 25 and driven wheel 26, wherein motor 10 directly connects speed reducer 38, described motor (10) and speed reducer (38) Constituting the horizontal driving device of the equipment, the two-way power output end of the reducer 38 is connected to the first half coupling 7 through the second half coupling 42 and the cardan shaft 8, and the first half coupling 7 drives the driving wheel 25 to move.

[0017] One end of the oil cylinder 13 is fixedly installed in the middle of the oil cylinder installation beam 11, and the other end is installed on the trolley 9 through the hinge shaft. The operator manually controls the expansion and contraction of the oil cylinder 13, and drives a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com