Lifting mechanism network and lifting mechanism synchronizing method

A lifting mechanism and lift technology, which is applied in the direction of lifting frame, lifting device, measuring device, etc., can solve the problems of unsynchronized lifting and lowering of the lift and other potential safety hazards, so as to achieve synchronous lifting, avoid potential safety hazards, and reduce potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

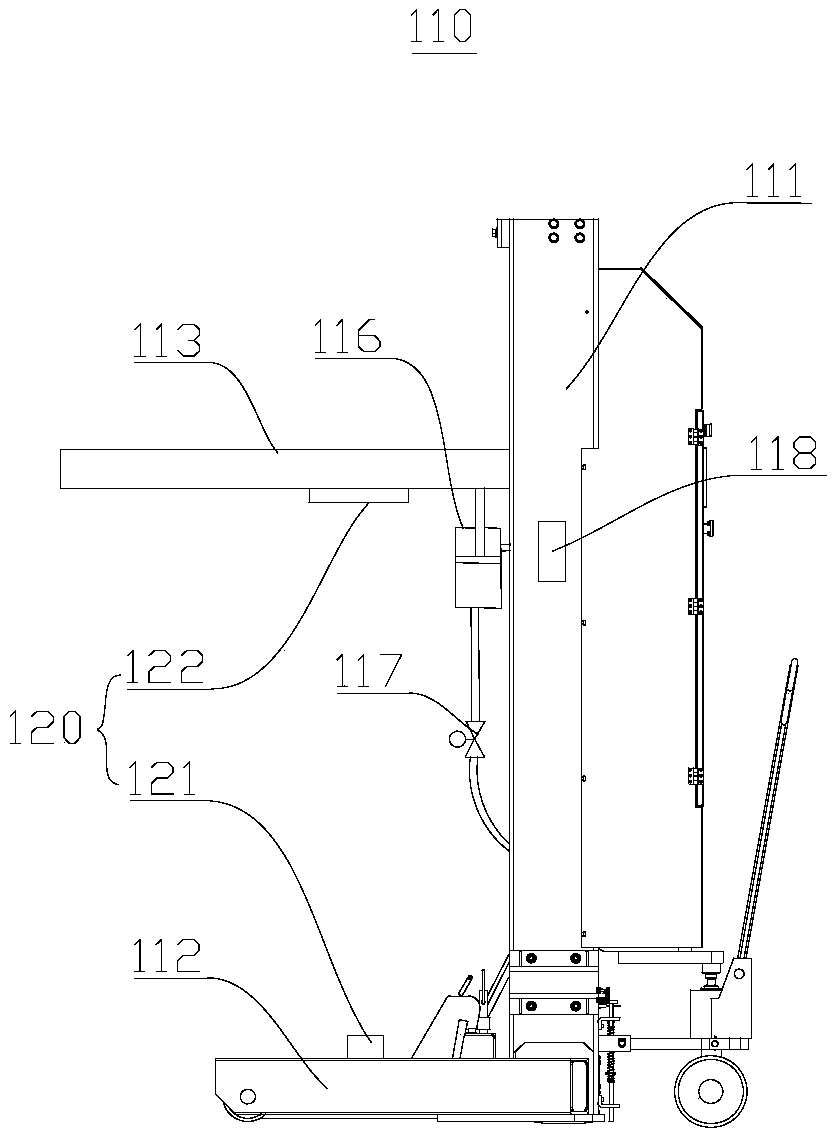

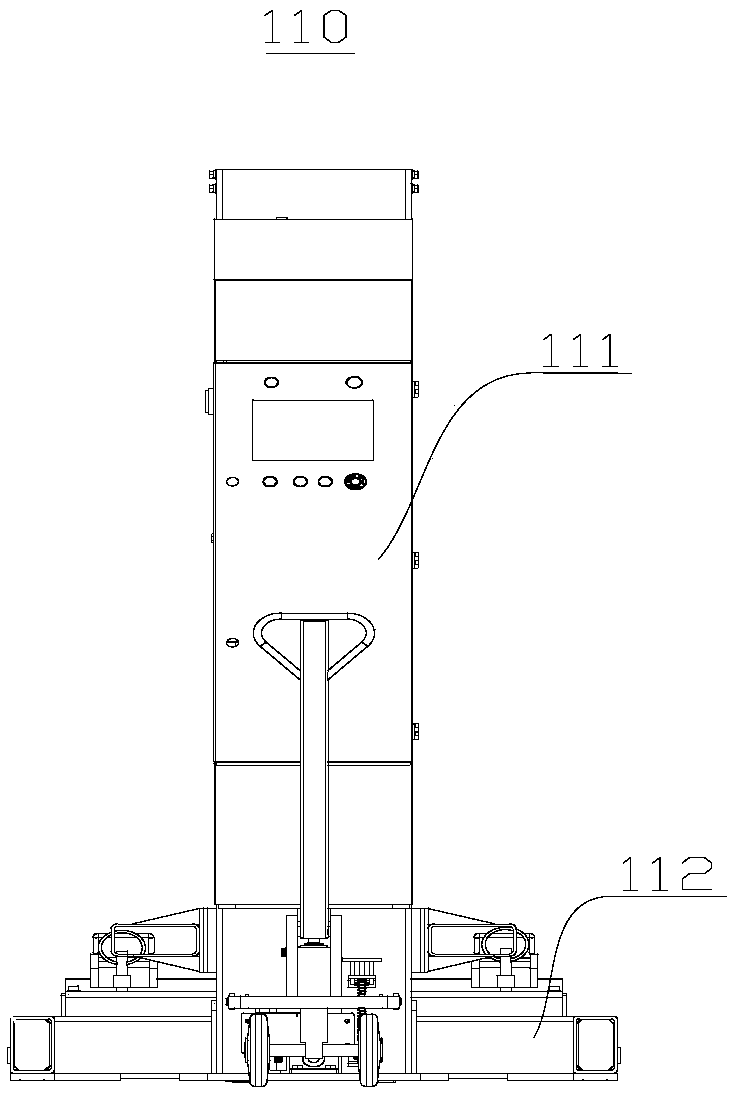

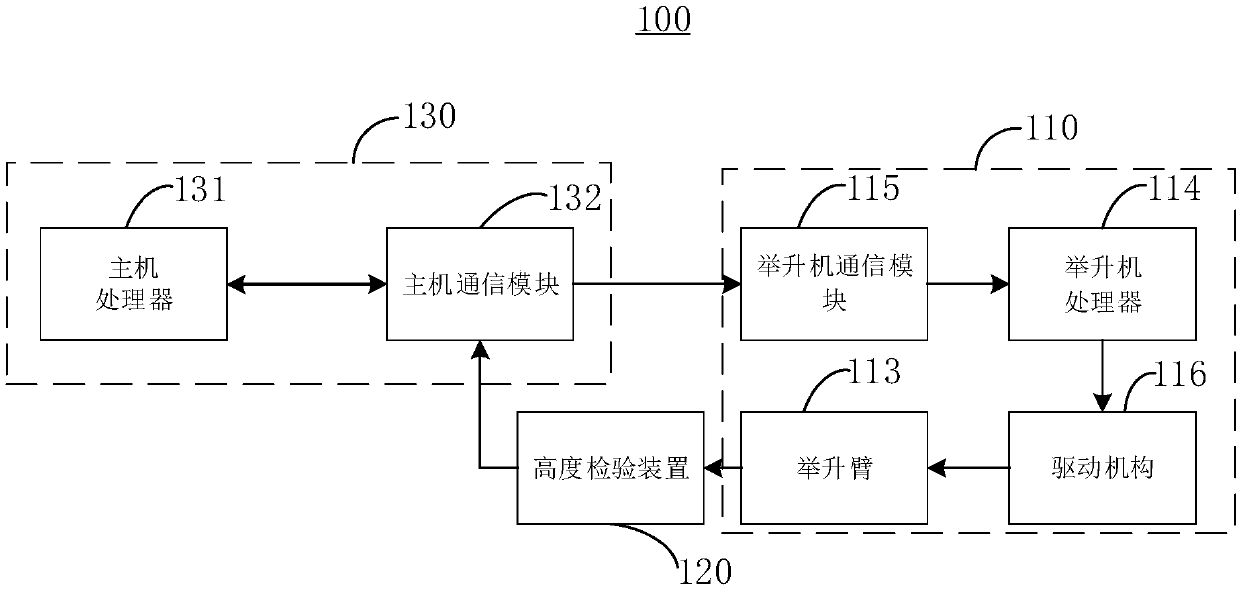

[0034] Please refer to Figure 1 to Figure 3 , the lifting mechanism network 100 provided by the present invention includes a plurality of lifts 110 , a plurality of height detection devices 120 and a host 130 . Each lift 110 is communicatively connected to the host computer 130 , and each height detection device 120 is communicatively connected to the host computer 130 , and the host computer 130 is used to adjust the lifting height of multiple lifts 110 .

[0035] Further, each lift 110 includes a body 111 , a base 112 , a lift arm 113 , a driving mechanism 116 , a lift processor 114 , a lift communication module 115 and a card reader 118 .

[0036] Wherein, the lifting arm 113 is arranged on the fuselage 111, the base 112 is used for supporting the fuselage 111 and the lifting arm 113, and the lifting arm 113 is used for lifting the vehicle.

[0037]Further, the driving mechanism 116 of the lifting arm 113 of the lift 110 can be selected as a driving mechanism 116 such as ...

no. 2 example

[0050] The lifting mechanism synchronization method 200 provided in this embodiment is applied to the lifting mechanism networking 100 provided in the first embodiment, please refer to Figure 4 , the lifting mechanism synchronization method 200 includes:

[0051] 210: Before the lifting operation, the operator swipes the card to authorize the lift 110 to be lifted, so as to ensure that only the lift 110 that has been swiped is used for the lifting operation, and the host 130 receives the lift 110 Enter the authorization notice of the lifting mechanism network 100 , confirm the identity information of all the lifts 110 entering the lifting mechanism network 100 , and the operator starts the lifting operation of all the lifts 110 in the lifting mechanism network 100 .

[0052] 220: When all the lifts 110 in the lifting mechanism network 100 are performing lifting operations, each height detection device 120 of each lift 110 in the lifting mechanism network 100 checks the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com