Hydraulic wedge block type supporting device

A wedge type and wedge technology, applied in the field of dynamic testing, can solve problems such as supporting the auxiliary flywheel and changing equipment characteristics, and achieve the effects of high reliability, convenient operation, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by specific embodiment the present invention is described in further detail:

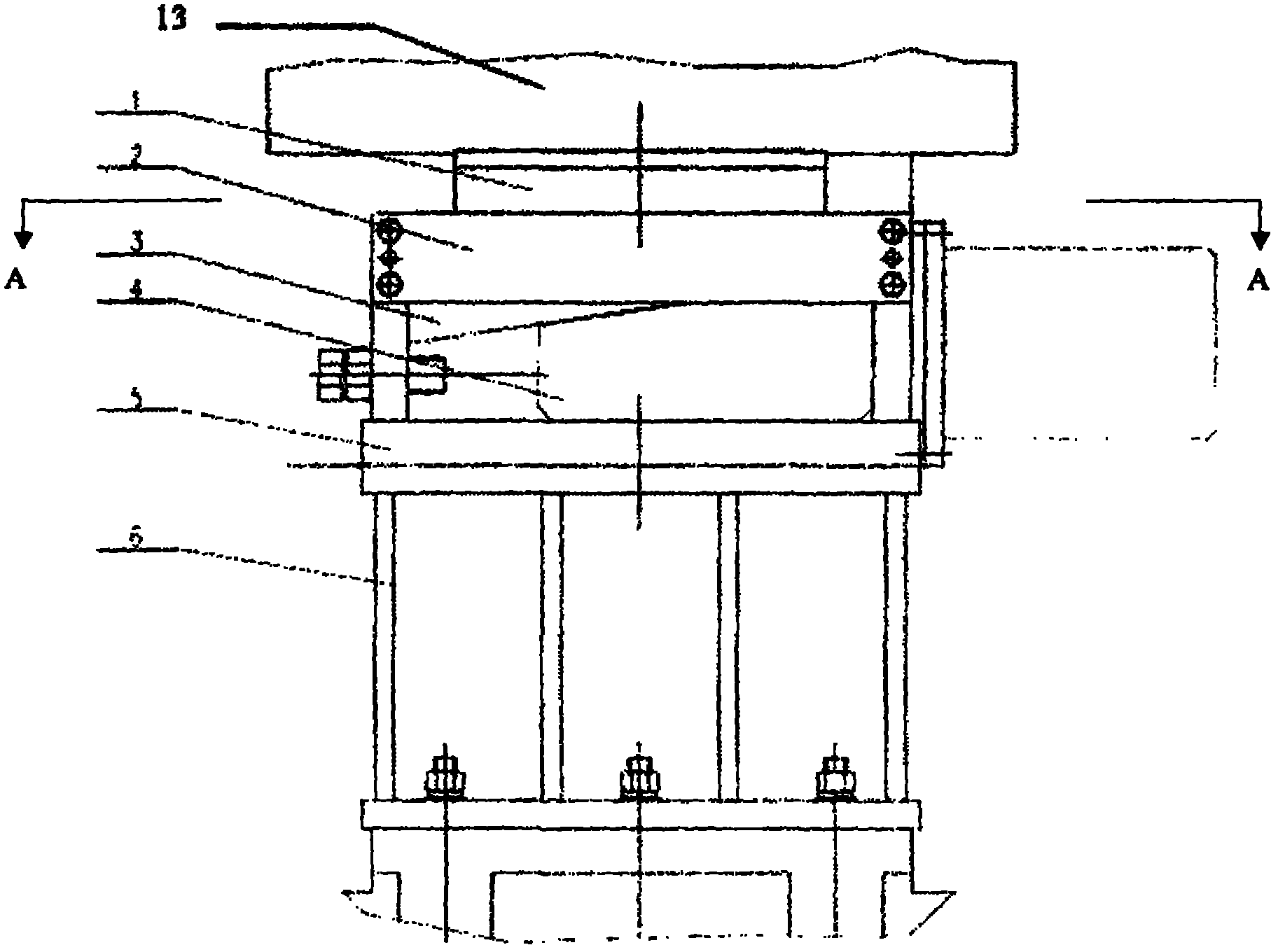

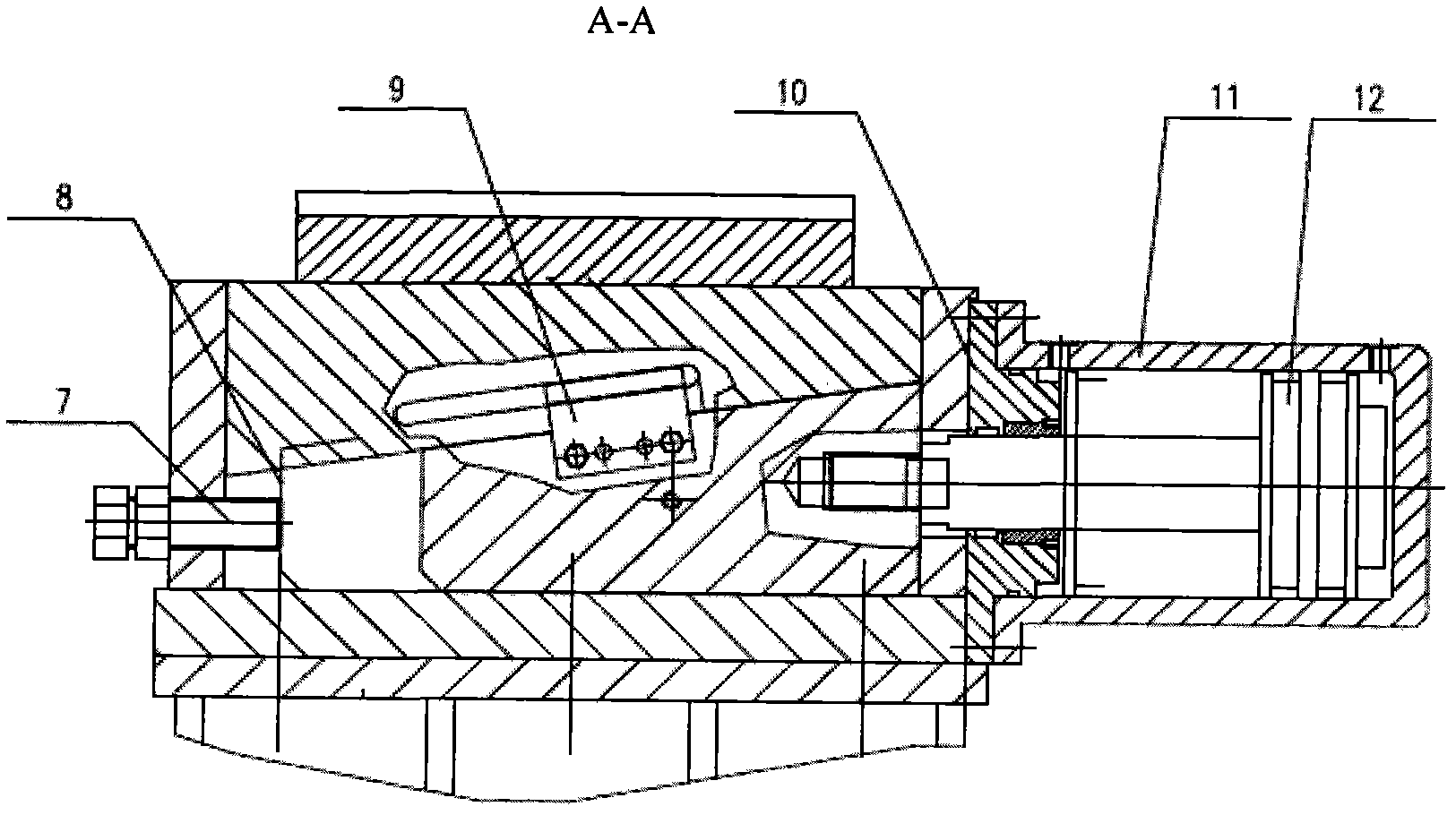

[0015] Please also see figure 1 and figure 2 ,in, figure 1 It is a schematic structural outline diagram of a preferred embodiment of the hydraulic wedge type support device of the present invention, figure 2 for figure 1 A-A cutaway view. The hydraulic wedge support device of the present invention includes a support arc plate 1, a side baffle plate 2, an upper wedge 3, a lower wedge 4, a frame 5, a support 6, a limit bolt 7, a guide block 9, and an oil cylinder cover 10, oil cylinder 11, piston rod 12, auxiliary flywheel 13. Wherein, the support 6 is designed into a frame shape, and its front end is connected to the auxiliary flywheel 13 through the support arc plate 1, and the upper wedge 3 and the lower wedge 4 are placed in the frame, and the length of the upper wedge 3 is the same as The inner cavity lengths of the support frame 5 are equal, therefore, the upper wedge 3 only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com