Modularized vehicle position regulating system

An adjustment system and modular technology, applied in vehicle components, elastic suspension, suspension, etc., can solve problems such as the inability of adjustment methods to meet the requirements of use, the decline of vehicle handling performance and ride comfort, and the inability to adjust the stiffness characteristics of elastic elements. , to achieve the effects of excellent anti-corrosion and anti-oxidation properties, weight loss and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a detailed description of the vehicle attitude adjustment system in conjunction with the accompanying drawings:

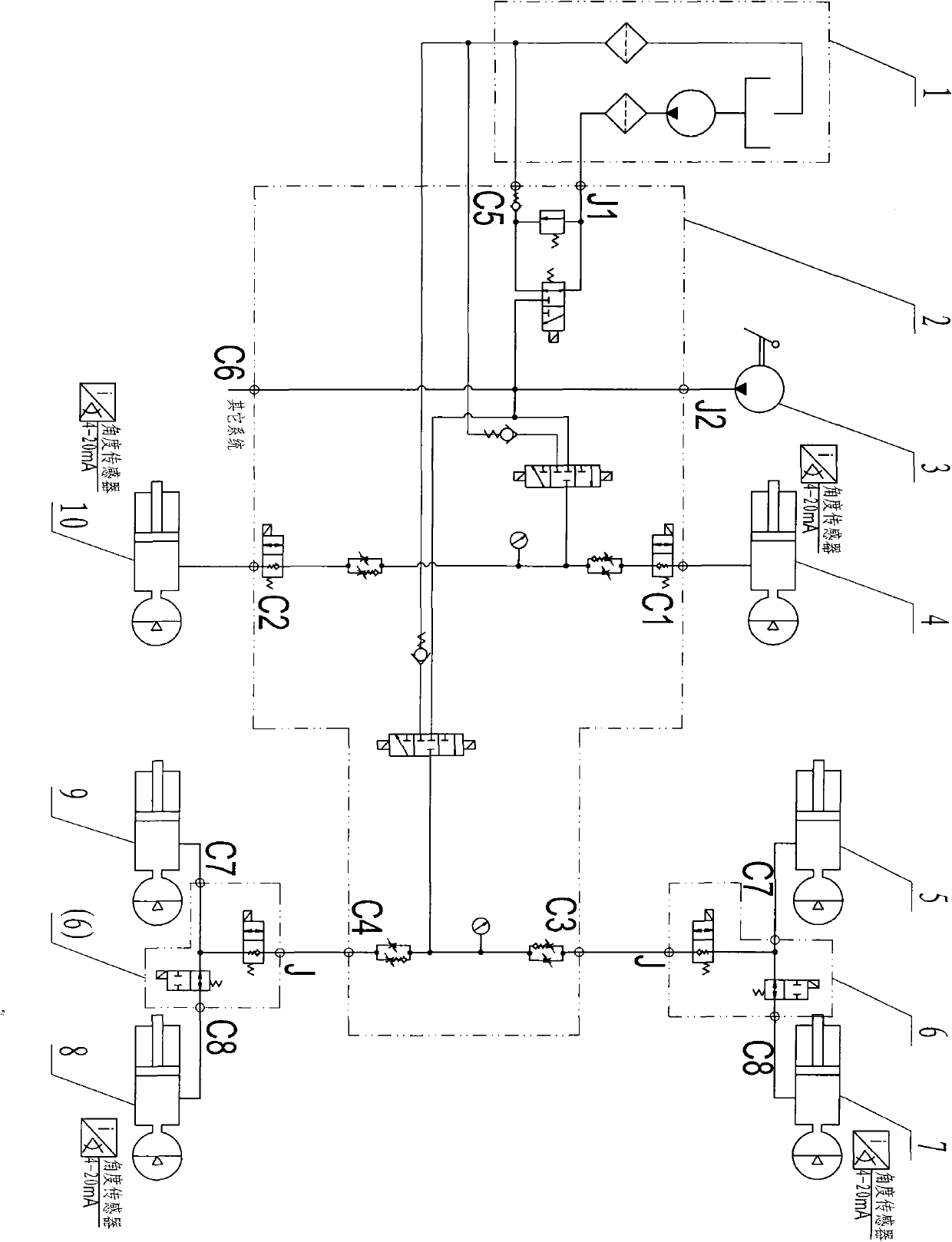

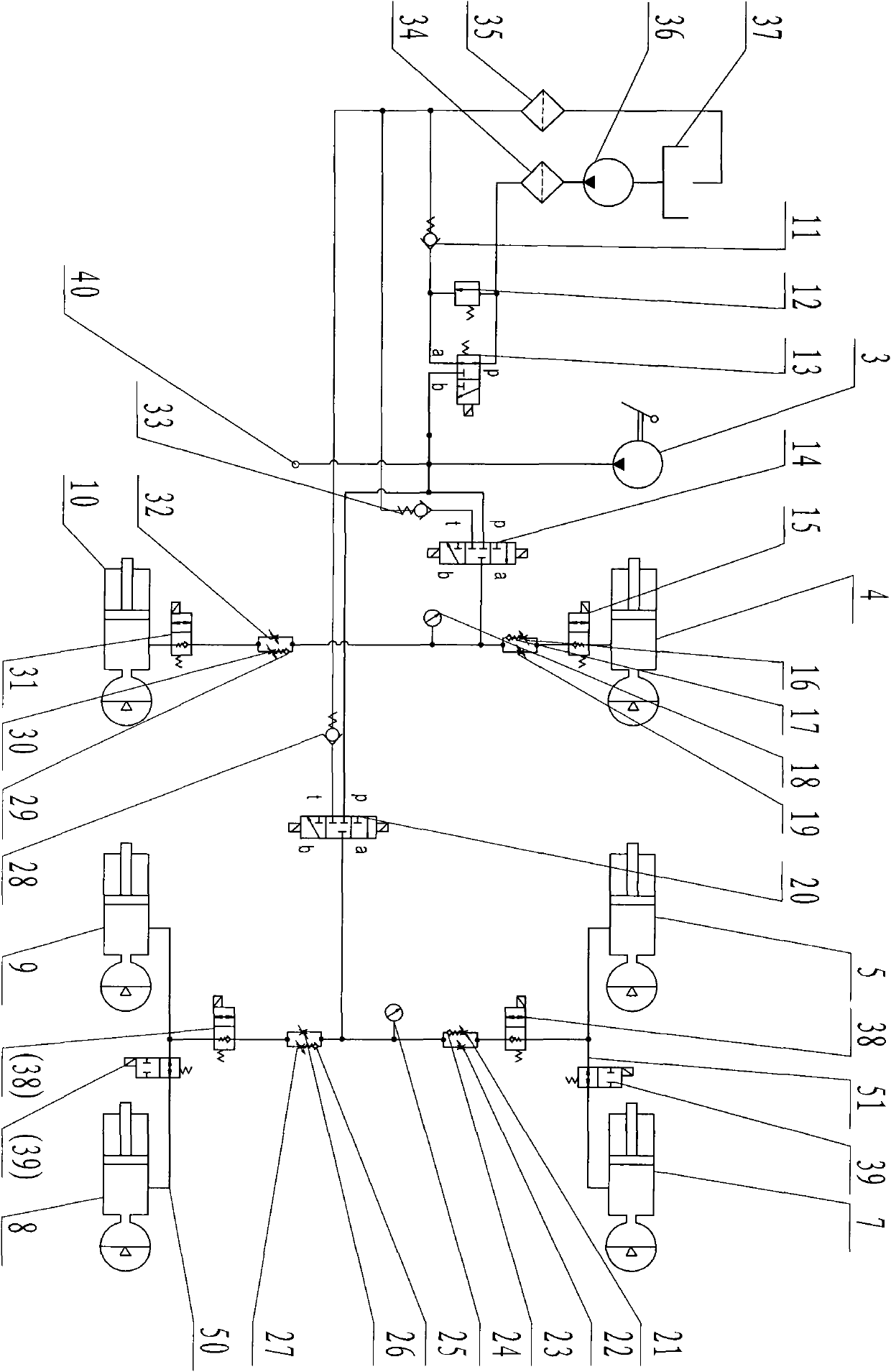

[0020] figure 1 The schematic diagram of the vehicle attitude adjustment system is shown.

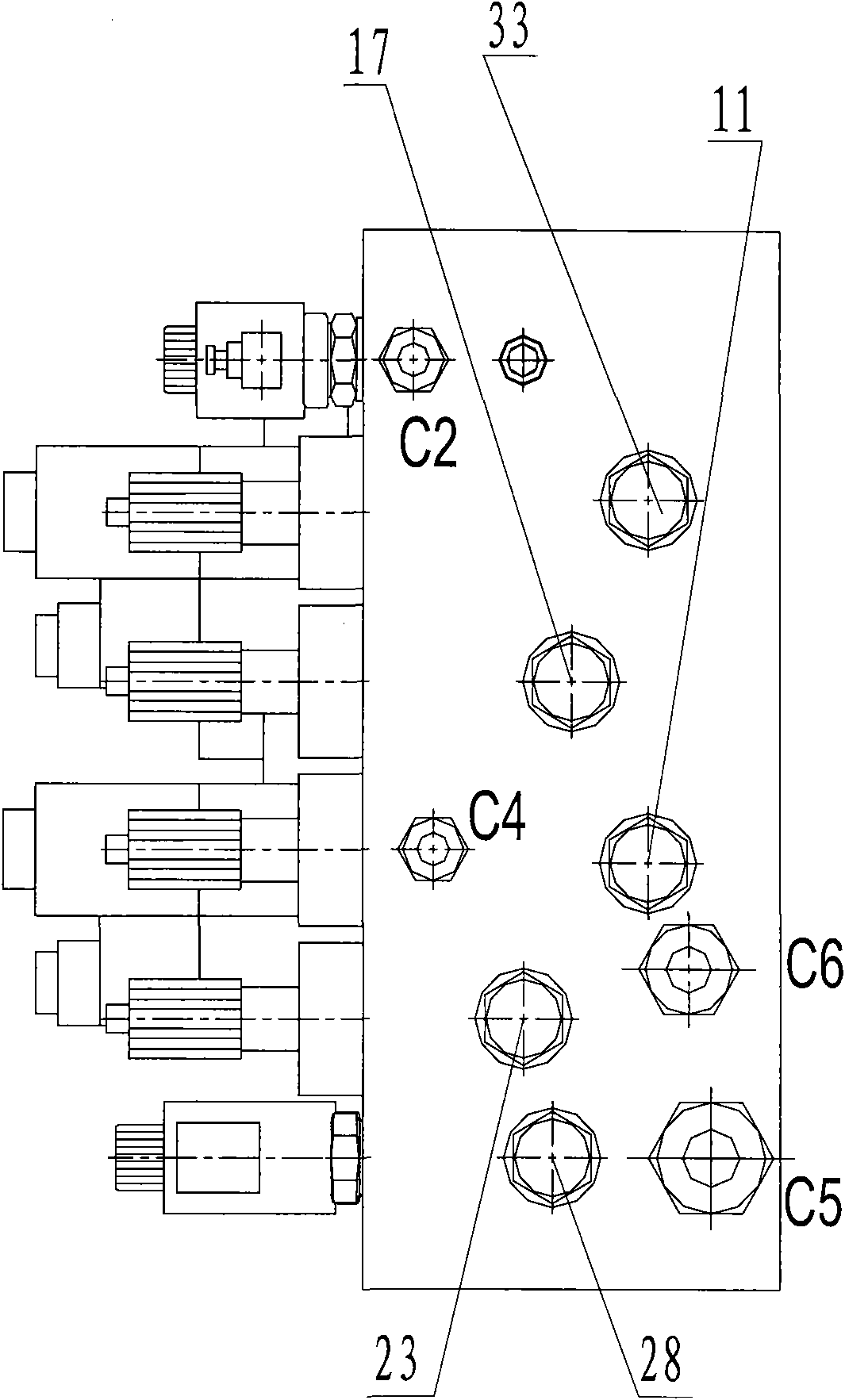

[0021] The vehicle attitude adjustment system consists of a system power source 1, a hydraulic device, a first right oil and gas suspension 4, a second right oil and gas suspension 5, a third right oil and gas suspension 7, a third left oil and gas suspension 8, and a second left oil and gas suspension 9. The left one is composed of oil and gas suspension 10, electronic control device, cables and sensors, and each part is connected by high-pressure hard pipes (or hoses). Preferably, the hydraulic device in the present invention is composed of a suspension device control combination 2 and a communication hydraulic lock combination 6, but those skilled in the art can arbitrarily combine multiple integrated control valves according to actual needs to ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com