Integrated comprehensive heat management system for electric automobile

A technology of electric vehicles and management systems, applied in the direction of electric vehicles, vehicle energy storage, vehicle components, etc., can solve the problems of insufficient integration of thermal management systems, high energy consumption of vehicle thermal management systems, and unsatisfactory energy-saving effects. Achieve the effects of saving layout space, good economy and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

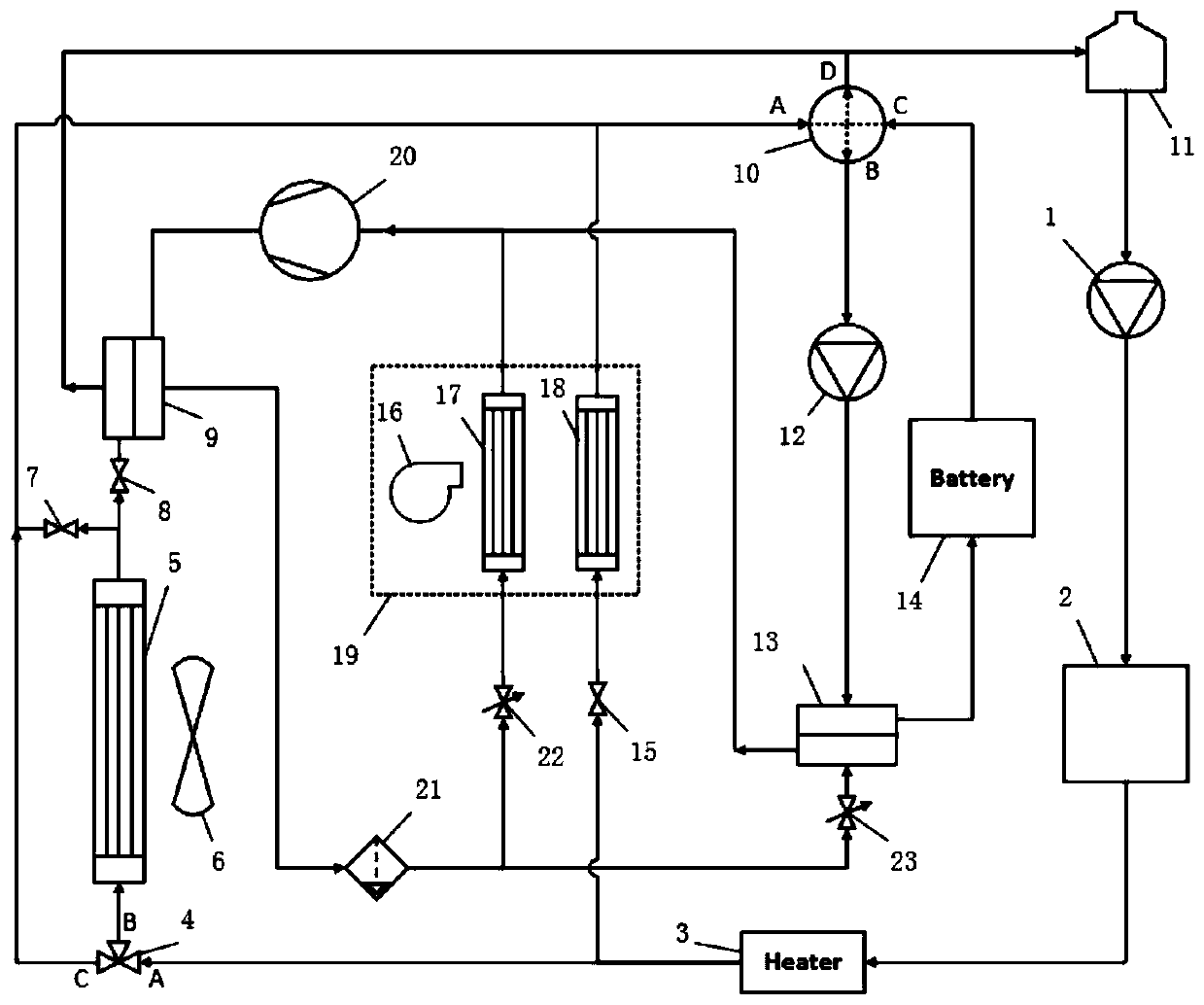

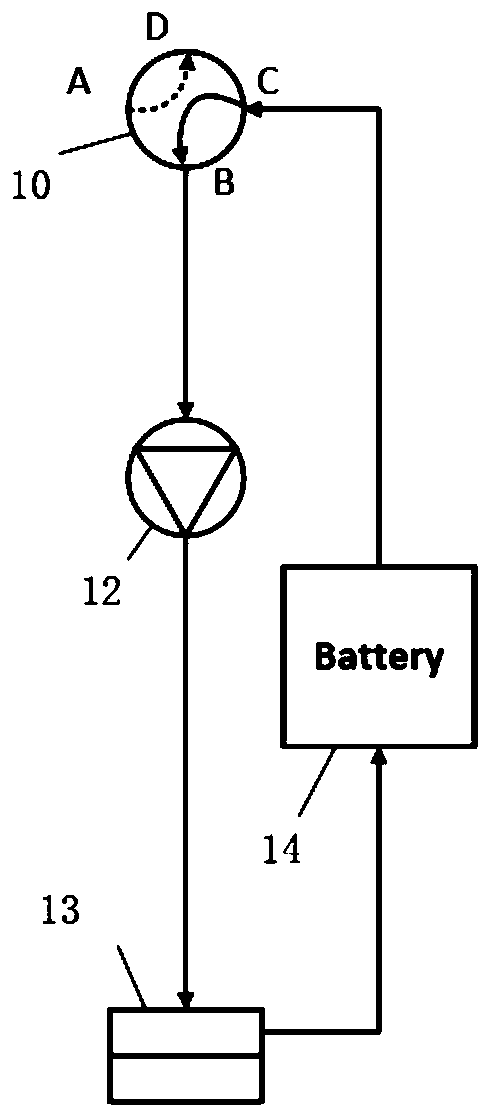

[0035] Such as figure 1 As shown, this application proposes an integrated thermal management system for electric vehicles, including a first water pump 1, an electric drive module 2, a heater 3, a radiator 5, a first heat exchanger 9, an expansion tank 11, and a second water pump 12. The second heat exchanger 13, the power battery pack 14, the evaporator 17, the warm air core 18, the air conditioner box 19, the electric compressor 20 and the liquid storage drying pot 21, each component passes through the pipeline and is installed in the pipeline The four-way valve 10, the three-way valve 4, the straight-through valve, and the expansion valve are connected to form a plurality of circuits that respectively perform thermal management and control on the power battery pack 14, the electric drive module 2, and the passenger compartment. The system sets an electric fan 6 next to the condenser for accelerating air flow to enhance heat exchange and is connected to the vehicle controlle...

Embodiment 2

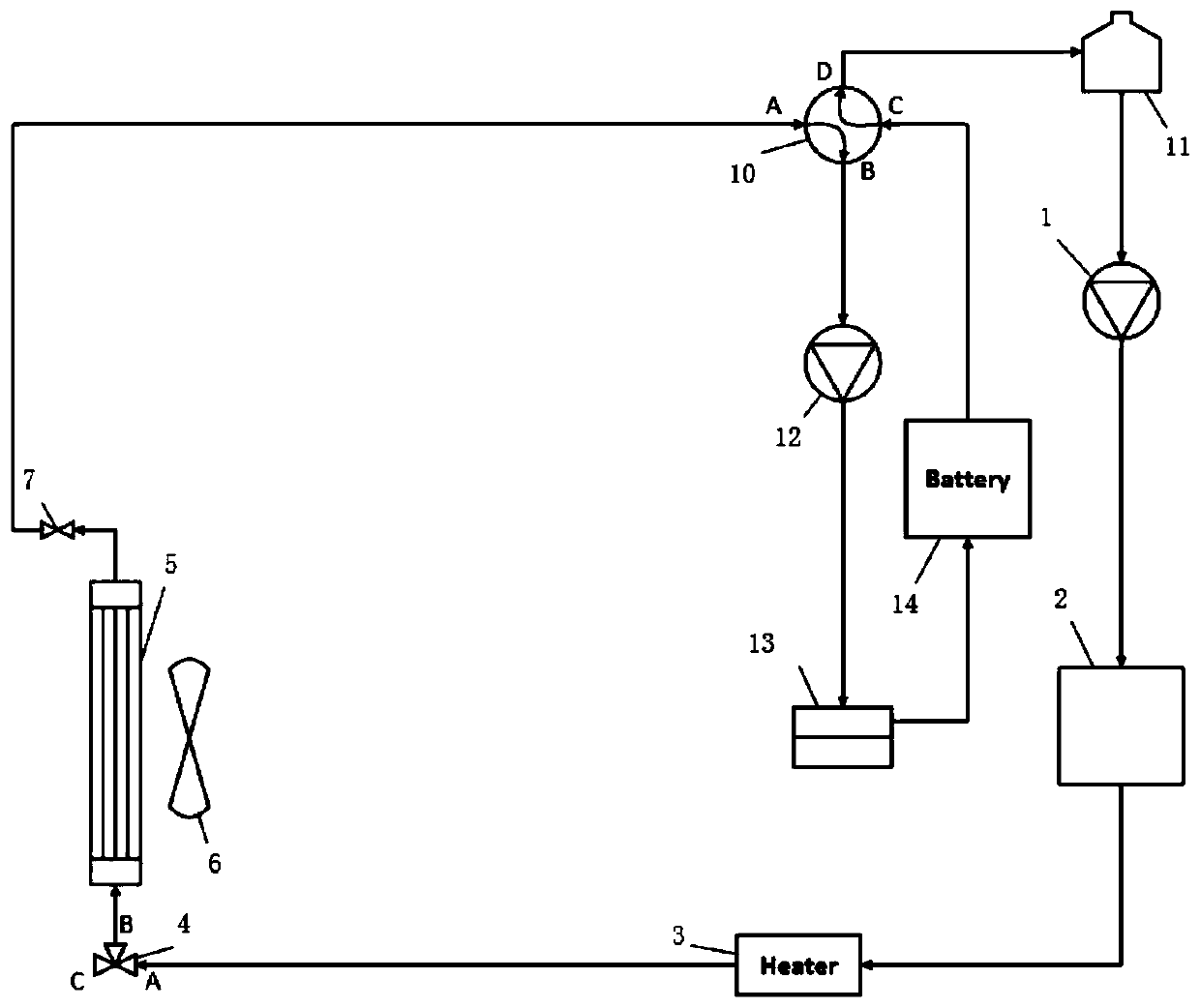

[0056] Figure 12 Shown is another form of realization of the thermal management system of the present application. The heater 3 is arranged upstream of the branch road where the warm air core 18 is located. The water tank 11, the first water pump 1, the electric drive module 2, and the third straight-through valve 15 (the third straight-through valve 15 is opened at this time, and the port A of the three-way valve 4 is closed), then flows into the heater 3 to heat up, and then flows through the The warm air core 18, by turning on the electric blower 16, drives the airflow to be heated when passing through the warm air core 18, then flows into the passenger compartment for heating and heating, and finally passes through the four-way valve 10 (parallel mode, ports A and D are connected, ports B and C communicate) and get back to the expansion tank 11. And when the temperature of the power battery pack 14 is low and the heat generated by the electric drive module 2 cannot meet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com