Bubble detection system and bubble detection method for display panel

A technology for displaying panel bubbles and display panels, which is applied in the direction of measuring devices, test sample preparation, sampling, etc., which can solve the problems of poor accuracy of detection results and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

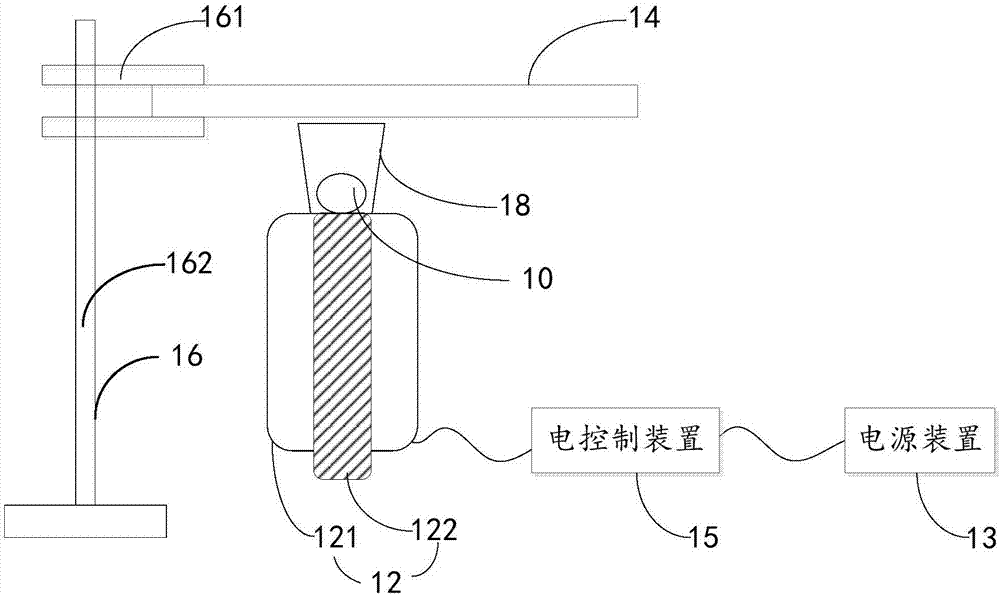

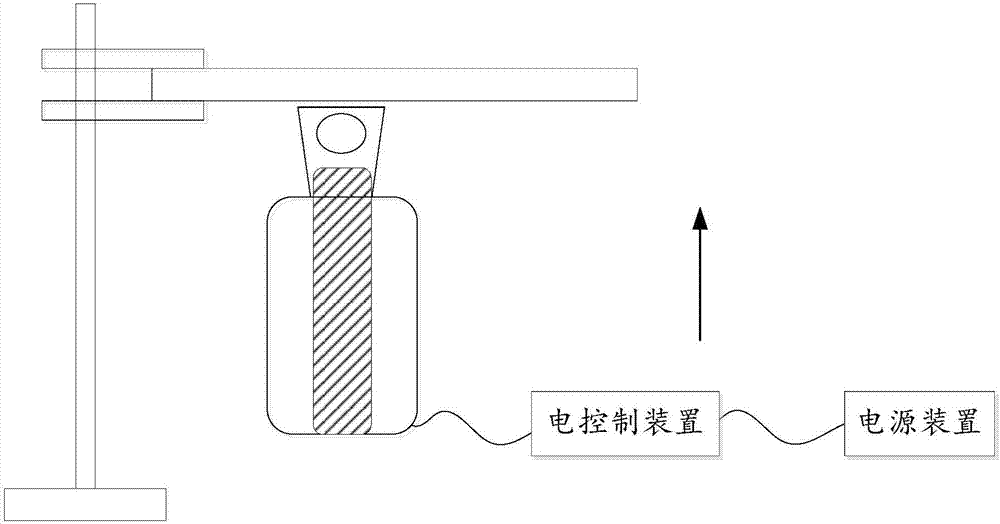

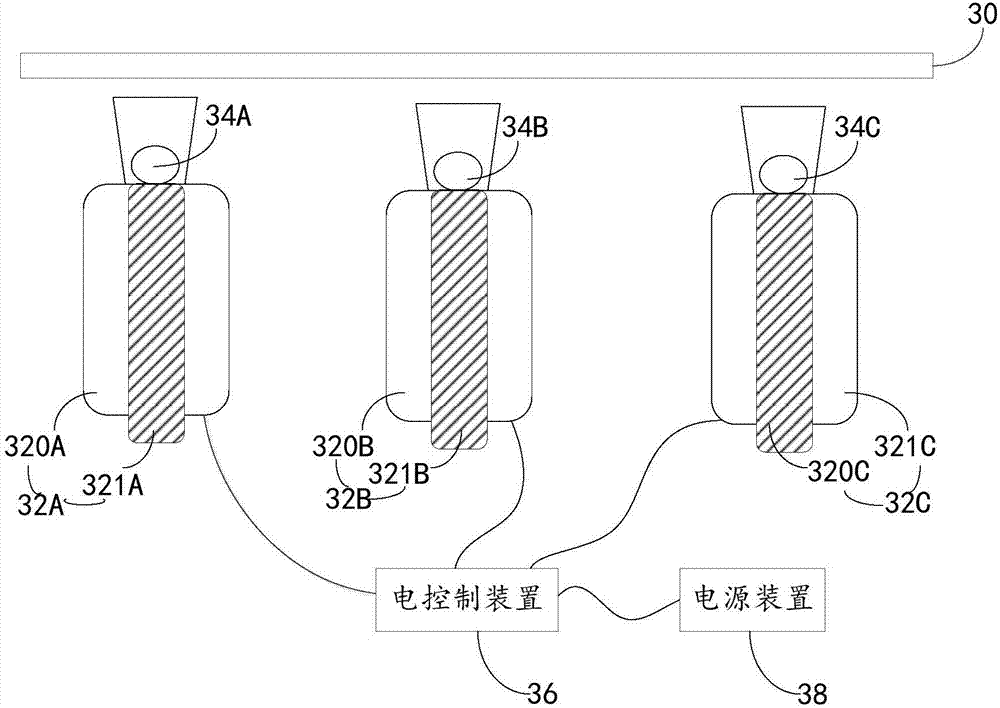

[0014] see figure 1 , figure 1 It is a schematic structural diagram of an embodiment of a display panel air bubble detection system of the present invention, and the detection system includes:

[0015] The collision body 10, specifically, the collision body 10 may be a sphere, a cube, a cuboid, etc., and its material may be metal or plastic.

[0016] The driving device 12 includes a driving element 121 and a moving element 122. The driving element 121 drives the moving element 122 to move, and the moving element 122 hits or drives the collision body 10 to hit the display panel 14 to measure the bubble condition of the display panel 14; specifically, the above-mentioned The moving direction of the moving element 122 is toward the display panel 14 , so that the moving direction of the collision body 10 is also toward the display panel 14 . In one application scenario, the moving element 122 is integrally formed with the collision body 10, that is, the collision body 10 is one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com