Vehicle collision-proof beam

A technology of anti-collision beams and automobiles, which is applied to vehicle parts, vehicle safety arrangements, bumpers, etc., can solve the problems of inability to guarantee safety standards, high structural fit and precision, and high manufacturing costs, so as to reduce injury index and improve safety Sexuality, the effect of protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

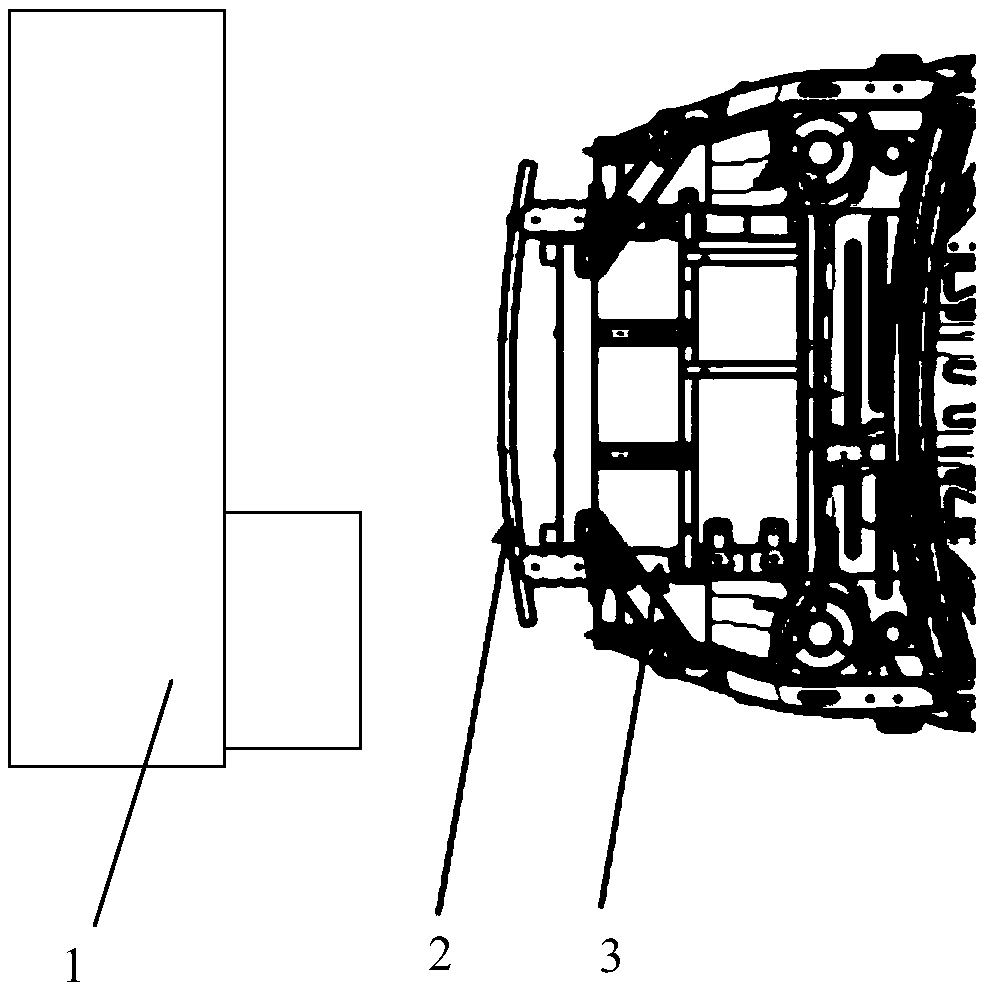

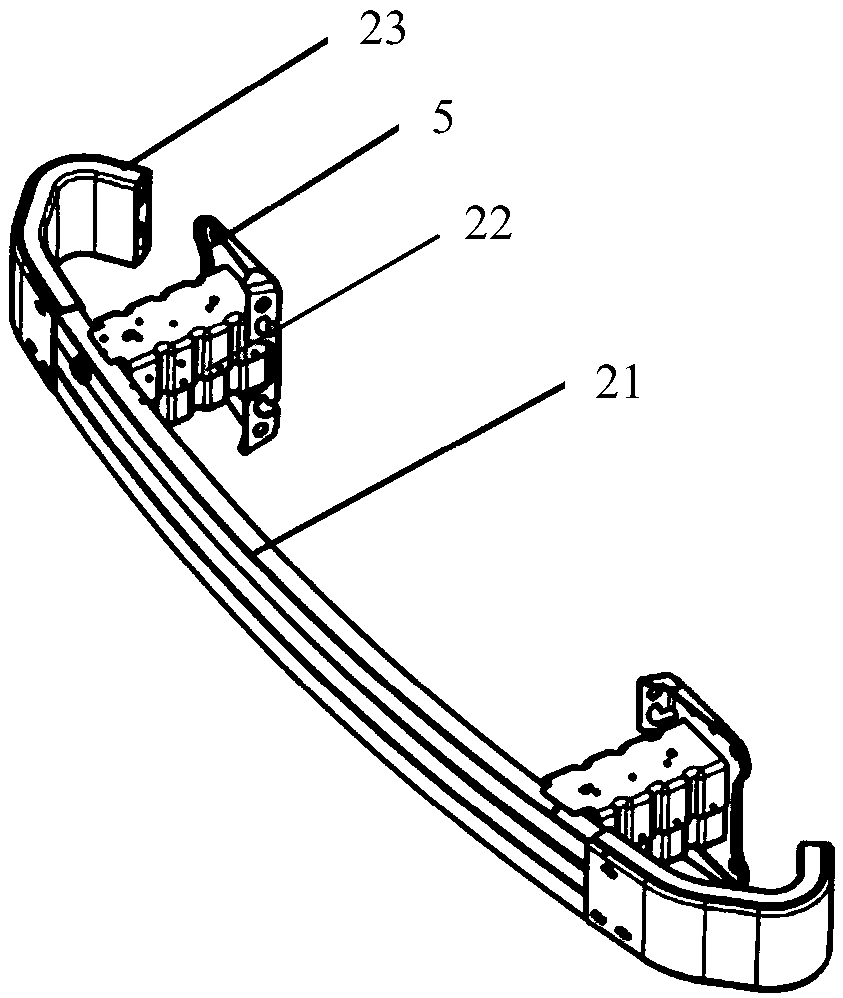

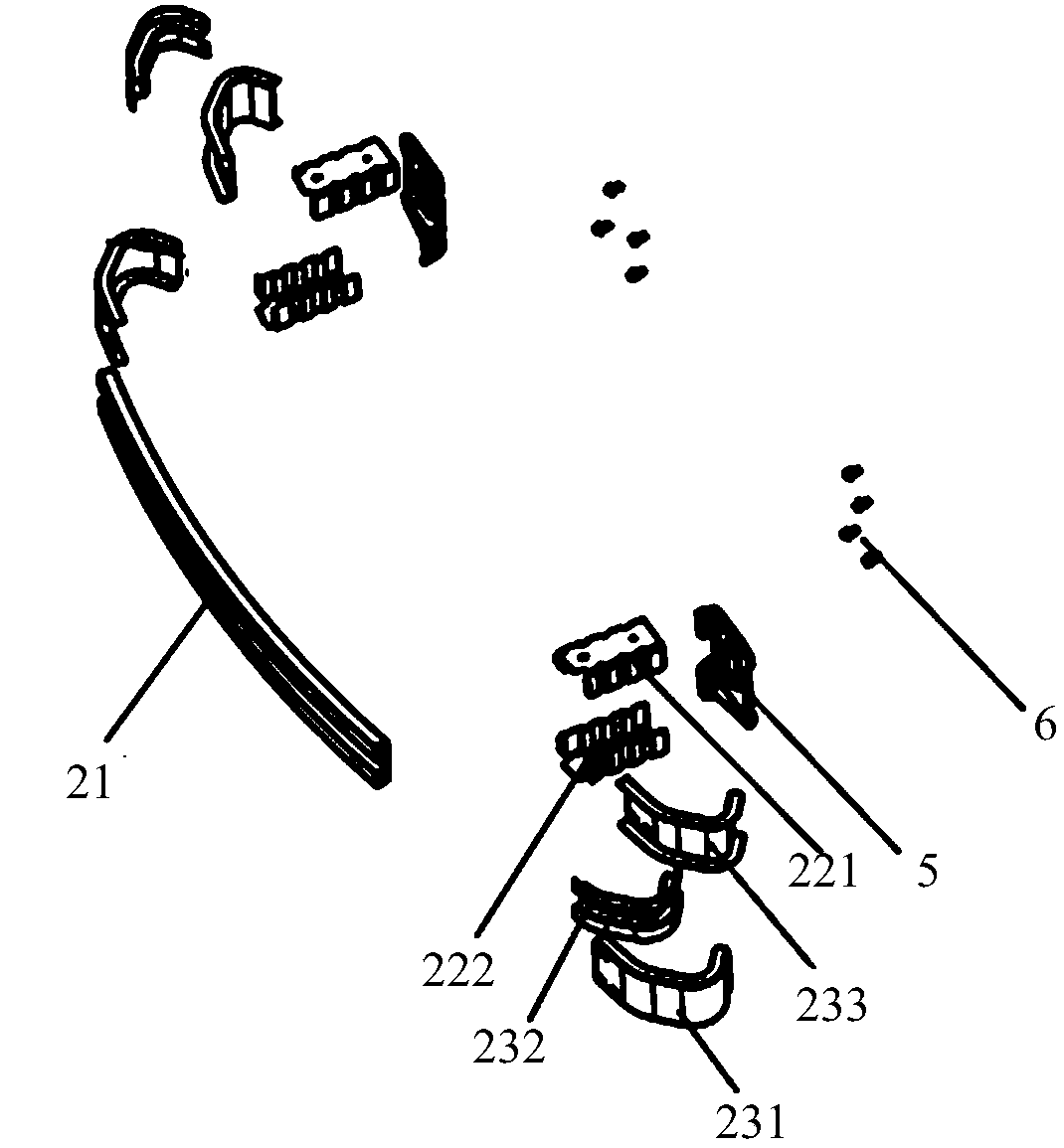

[0034] Such as figure 2 and image 3 As shown, the present embodiment provides an automobile anti-collision beam, including a main beam 21, an energy absorbing box 22 and a flange 5, the main beam 21 is connected to the front longitudinal beam 3 of the automobile through the flange 5 and bolts 6, and the main beam 21 An energy-absorbing box 22 is arranged between the front side member and the front longitudinal beam 3 . At present, there are many types of materials and manufacturing processes used for the main beam of automobiles, mainly divided into high-strength steel anti-collision beams; steel ultra-high-strength anti-collision beams; aluminum anti-collision beams, etc. The manufacturing process is mainly divided into: rolling process, stamping process; casting process; extrusion process, etc. The left / right crash box 22 is divided into an upper crash box 221 and a lower crash box 222, and the upper crash box 221 and the lower crash box 222 are connected by welding. Th...

Embodiment 2

[0041] The main girder in this embodiment is made of alloy steel with a model number of 980DP and a thickness of 1.8 mm. The width of the main girder is 45 mm and the height is 110 mm. The hook type of the side beam is a three-section two-fold structure. From one end connected to the main beam, the first section is an extension section on both sides of the main beam, with a length of 135mm. It is 135mm, and the third section is at an angle of 125 degrees to the transverse direction of the vehicle. One end is connected to the second section, and the other end is suspended in the air. The distance from the suspended end on the side beam to the shotgun structure is 30mm, and the rest is the same as in the first embodiment.

Embodiment 3

[0043] The main girder of this embodiment adopts the alloy steel of model 1100DP and thickness of 1.0 mm. The width of the main girder is 40 mm and the height is 105 mm; From the beginning, the first section is the extension section on both sides of the main beam, the length is 120mm, the second section is at an angle of 45 degrees to the transverse direction of the vehicle, and the length is 120mm, and the third section is at an angle of 123 degrees to the transverse direction of the vehicle, one end of which is connected to the second section , the other end is suspended in the air, and the distance from the suspended end of the side beam to the shotgun structure is 15mm, and the rest is the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com