Production method for edible beer yeast powder

A technology of brewer's yeast powder and brewer's yeast, which is applied in the field of food manufacturing, can solve the problems of mineral loss, unsatisfactory production method of brewer's yeast powder, and limitation of the range of application of brewer's yeast powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

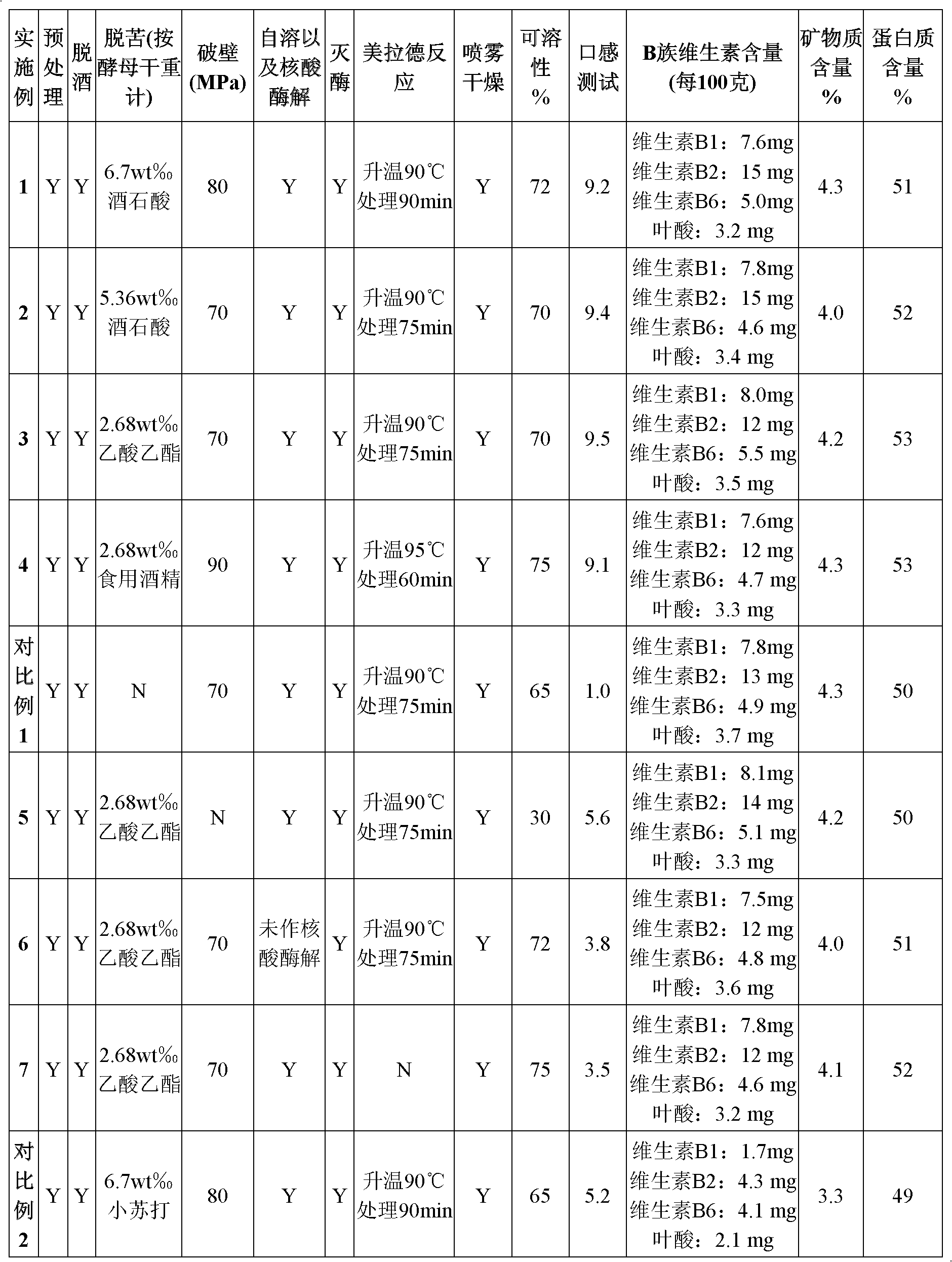

Examples

Embodiment 1

[0099] Preparation of Brewer's Yeast Powder No.1

[0100] 2000L of brewer's yeast slurry was mixed with water until the concentration of the dry weight of brewer's yeast was 10 wt%, passed through 80-mesh and 100-mesh sieves once respectively, and collected the yeast liquid.

[0101] The collected yeast is hydraulically fed into the press, and the pressure is kept within the range of 4.5-5kg to squeeze the yeast liquid until no filtrate flows out, and the yeast is collected.

[0102] The squeezed yeast is slurried to 15 wt%, and 6.7‰ tartaric acid (debittering agent) is added according to the dry weight of brewer's yeast for debittering treatment. After the debittering is finished, the slurry is forced into a press, and the pressed yeast is adjusted to 15wt%, washed and pressed twice.

[0103] The squeezed yeast was adjusted to 15wt% and pumped into the nano collider, the pressure was 80MPa, and the number of wall breaking cycles was 3 times.

[0104] Heat the broken yeast t...

Embodiment 2

[0106] Preparation of Brewer's Yeast Powder No.2

[0107] 2000L of brewer's yeast slurry was mixed with water until the concentration of the dry weight of brewer's yeast was 12 wt%, passed through 80-mesh and 100-mesh sieves once respectively, and collected the yeast liquid.

[0108] The collected yeast is hydraulically fed into the press, and the pressure is kept within the range of 4.5-5kg to squeeze the yeast liquid until no filtrate flows out, and the yeast is collected.

[0109] The squeezed yeast is slurried to 15 wt%, and 5.36‰ tartaric acid (debittering agent) is added according to the dry weight of brewer's yeast for debittering treatment. After the debittering is finished, the slurry is forced into a press, and the pressed yeast is adjusted to 15wt%, washed and pressed twice.

[0110] The squeezed yeast was adjusted to 15wt% and pumped into the nano collider, the pressure was 70MPa, and the number of wall breaking cycles was 3 times.

[0111] Heat the broken yeast to...

Embodiment 3

[0113] Preparation of Brewer's Yeast Powder No.3

[0114] 2000L of brewer's yeast slurry was mixed with water until the concentration of the dry weight of brewer's yeast was 12 wt%, passed through 80-mesh and 100-mesh sieves once respectively, and collected the yeast liquid.

[0115] The collected yeast is hydraulically fed into the press, and the pressure is kept within the range of 4.5-5kg to squeeze the yeast liquid until no filtrate flows out, and the yeast is collected.

[0116] The squeezed yeast is slurried to 15 wt%, and 2.68‰ ethyl acetate (debittering agent) (debittering agent) is added according to the dry weight of brewer's yeast for debittering treatment. After the debittering is finished, the slurry is forced into a press, and the pressed yeast is adjusted to 15wt%, washed and pressed twice.

[0117] The squeezed yeast was adjusted to 15wt% and pumped into the nano collider, the pressure was 70MPa, and the number of wall breaking cycles was 3 times.

[0118] He...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com