Lithium iron phosphate plastic housing cylindrical battery and preparation method thereof

A technology of plastic shell and lithium iron phosphate, which is used in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve the problems of difficult assembly of metal shell cylindrical batteries, unsatisfactory ion diffusion, and low yield. Achieve excellent safety performance, low cost, and improve the effect of short circuit resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

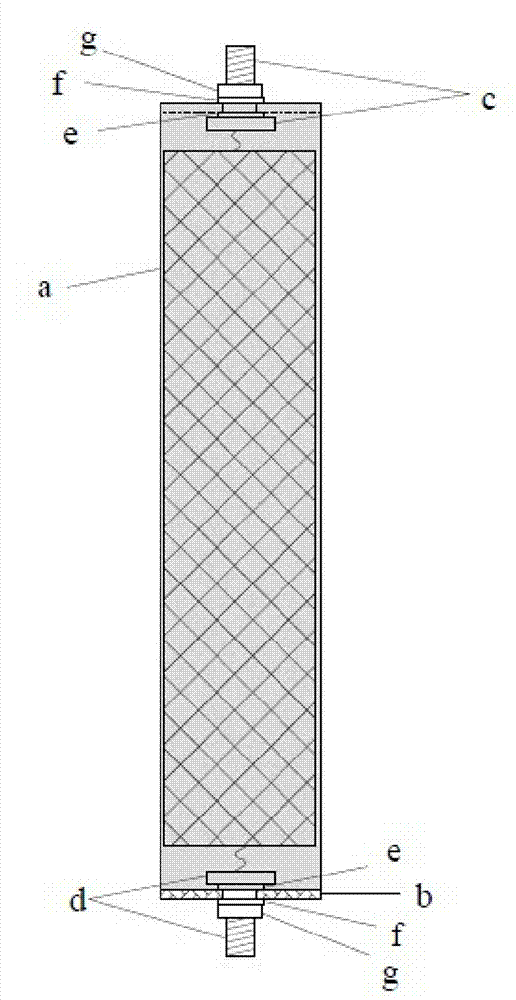

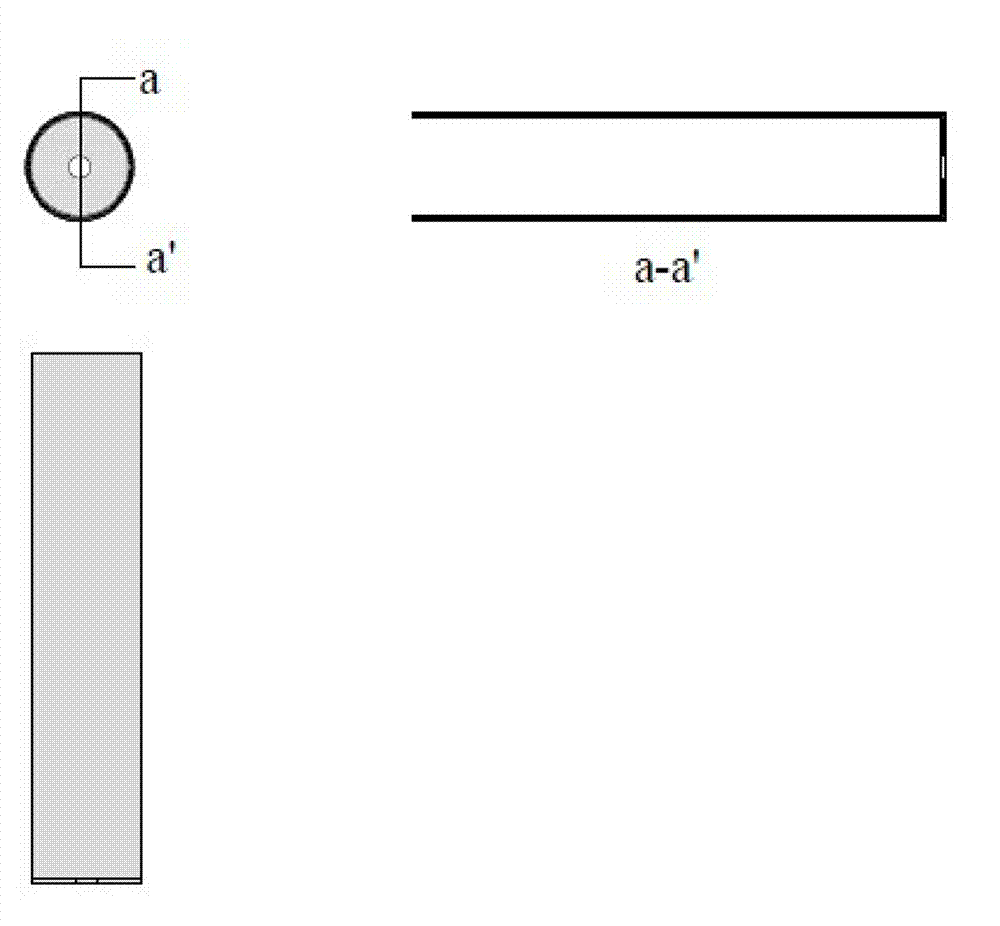

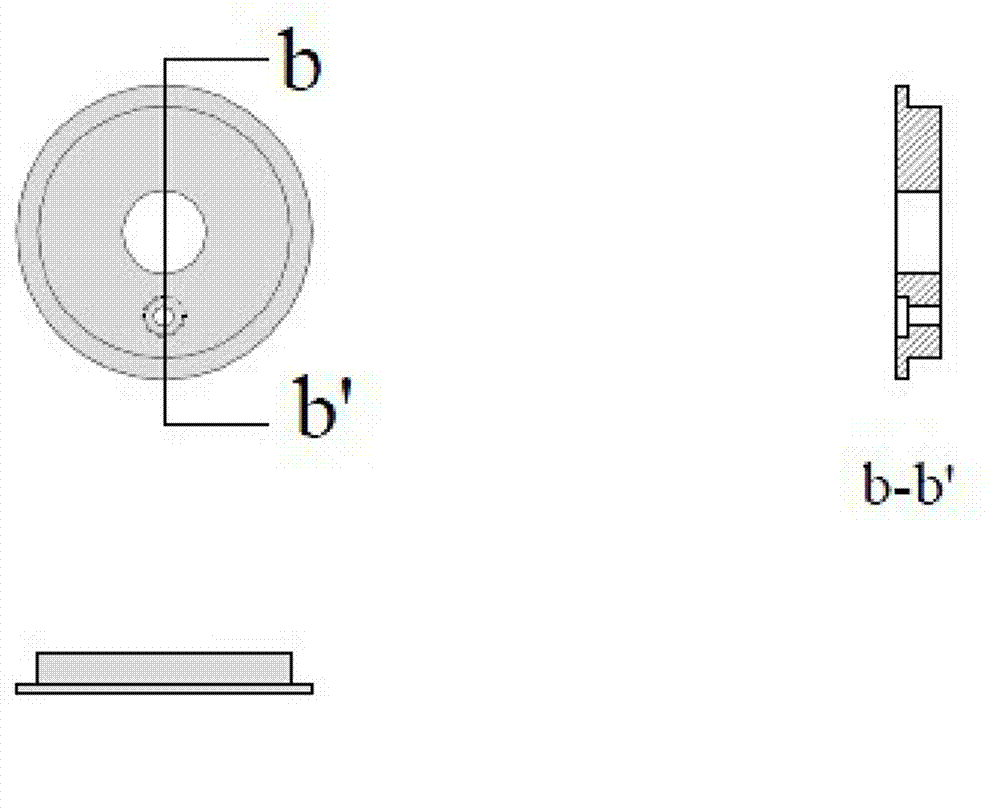

[0039] A cylindrical battery with a lithium iron phosphate plastic case, including a case, a winding core and an electrolyte. The winding core is a cylindrical winding core formed by adding positive and negative electrode sheets to the diaphragm; the positive electrode sheet is made by coating the positive electrode slurry with lithium iron phosphate as the main component on the aluminum foil, and the negative electrode sheet is made by coating the negative electrode slurry It is made of copper foil; the shell is mainly composed of a plastic shell, b end cover, c upper pole, d lower pole, e inner gasket, f outer gasket and g fixing nut, such as figure 1 shown. a The plastic shell is open at one end, and the other end is semi-sealed, leaving a round hole in the center, such as figure 2 As shown; the b end cover is a cylinder made of PP material that matches the open end of the plastic shell, with a round hole in the middle and a liquid injection hole at a position off the cen...

Embodiment 2

[0054] Keep the other schemes of Example 1 unchanged, only change the formula of the positive and negative electrode slurry: the positive electrode slurry is 7 parts by weight of polyvinylidene fluoride, 87 parts of lithium iron phosphate, 3 parts of Conductive carbon black, 3 parts of conductive graphite and N-methyl-2-pyrrolidone are reconciled into a slurry with a solid content of 35%; the negative electrode slurry is 89 parts by weight of graphite, 2 parts of conductive carbon black , 2 parts of conductive graphite, 2 parts of sodium carboxymethyl cellulose, 2.5 parts of styrene-butadiene rubber and 2.5 parts of water-based glue were mixed with deionized water to form a slurry with a solid content of 45%.

[0055] Several typical examples of preparation of the special diaphragm used in the winding core of the present invention are provided below.

Embodiment 3

[0057] Dissolve 3000g polyvinylidene fluoride, 6000g vinylidene fluoride-hexafluoropropylene copolymer, 800g polyacrylonitrile, 5000g polymethyl methacrylate into 50000g acetone, 2000g ethyl acetate, 1000g ethanol solvent, the dissolution temperature is 40-80 ℃, and then add 2500g of aluminum oxide and 2500g of silicon dioxide for stirring and dispersing to obtain a viscous slurry. Coat the viscous slurry prepared on the polypropylene microporous film with the coating equipment, and dry the diaphragm coated with the slurry in the oven of the coating equipment, and the dried diaphragm is vacuum-baked at 80°C , remove the residual solvent, and then obtain the diaphragm used in the winding core in the foregoing embodiment. According to the requirements of lithium-ion power battery manufacturers, the diaphragm can be made into diaphragms of different widths after cutting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com