66kV burst short circuit transformer

A transformer, 66kv technology, applied in the field of transformer manufacturing, can solve the problems that the wire cake is difficult to achieve the pre-tightening force, the short-circuit resistance of the winding is not enough, and the axial compression is not reliable, so as to optimize the insulation structure, simplify the drawing design, and improve the safety. The effect of the turn balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0024] This embodiment takes the SZ11-50000 / 66 burst short-circuit transformer as an example, which is a burst-short-circuit-resistant transformer with the largest capacity of 50,000 kVA in current domestic 66kV power grid.

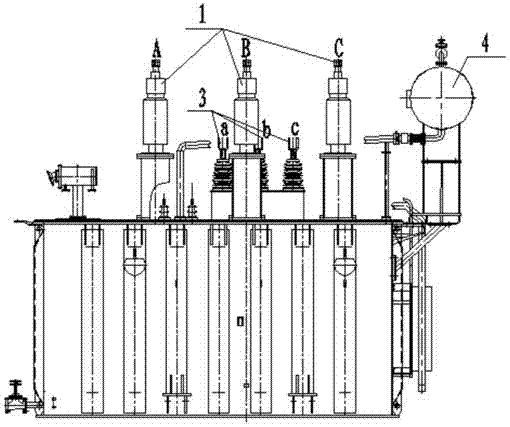

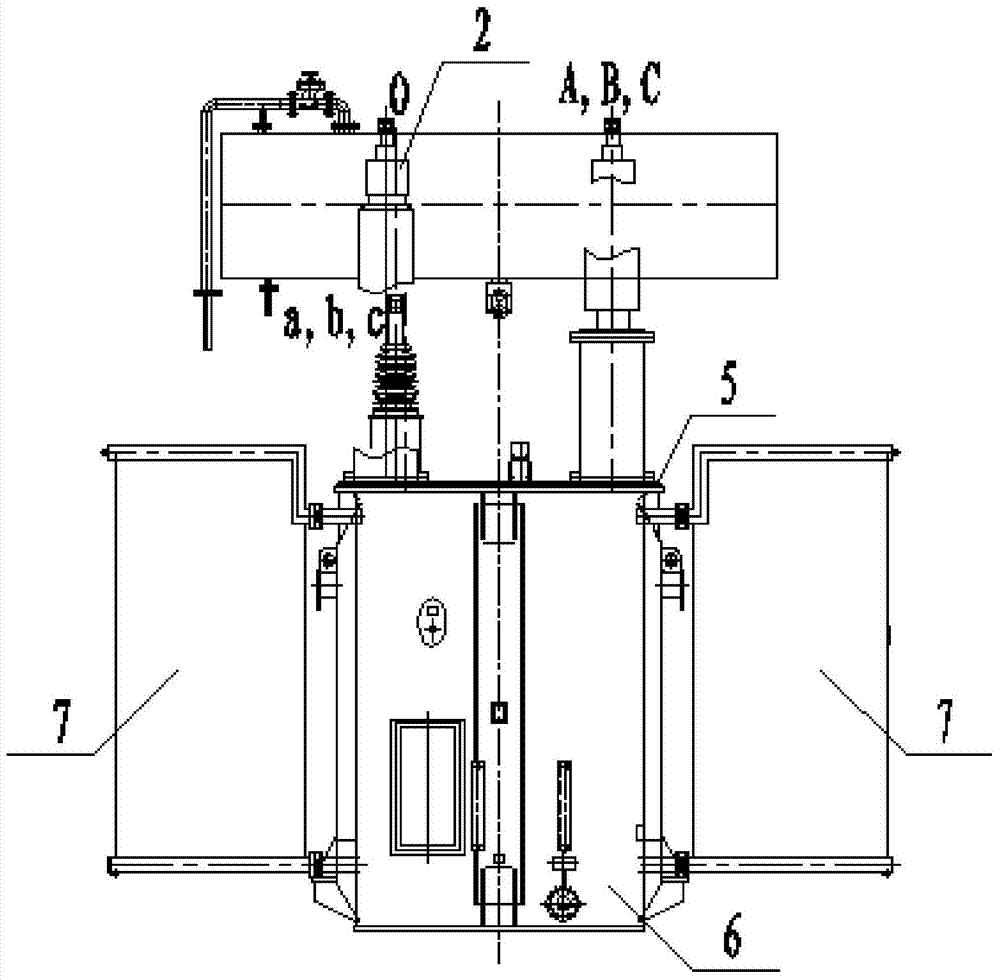

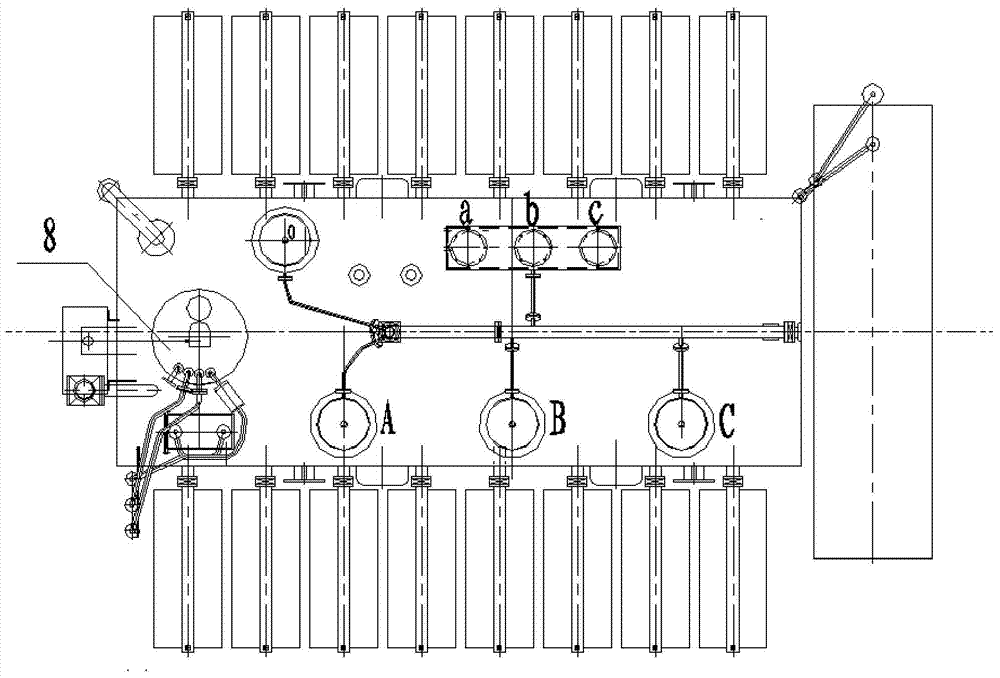

[0025] Such as Figure 1~3 As shown, the 66kV sudden short-circuit transformer of the present invention mainly includes: high-voltage bushing 1, neutral point bushing 2, low-voltage bushing 3, oil storage tank 4, tank cover 5, lower fuel tank 6, radiator 7, load Tap changer 8. All the bushings are directly led vertically from the tank cover 5, among which, the high-voltage bushing 1 is arranged on the high-voltage side, the neutral point bushing 2 and the low-voltage bushing 3 are arranged on the low-voltage side; the oil conservator 4 is parallel to the short axis of the transformer, and extends out of the transformer; radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com