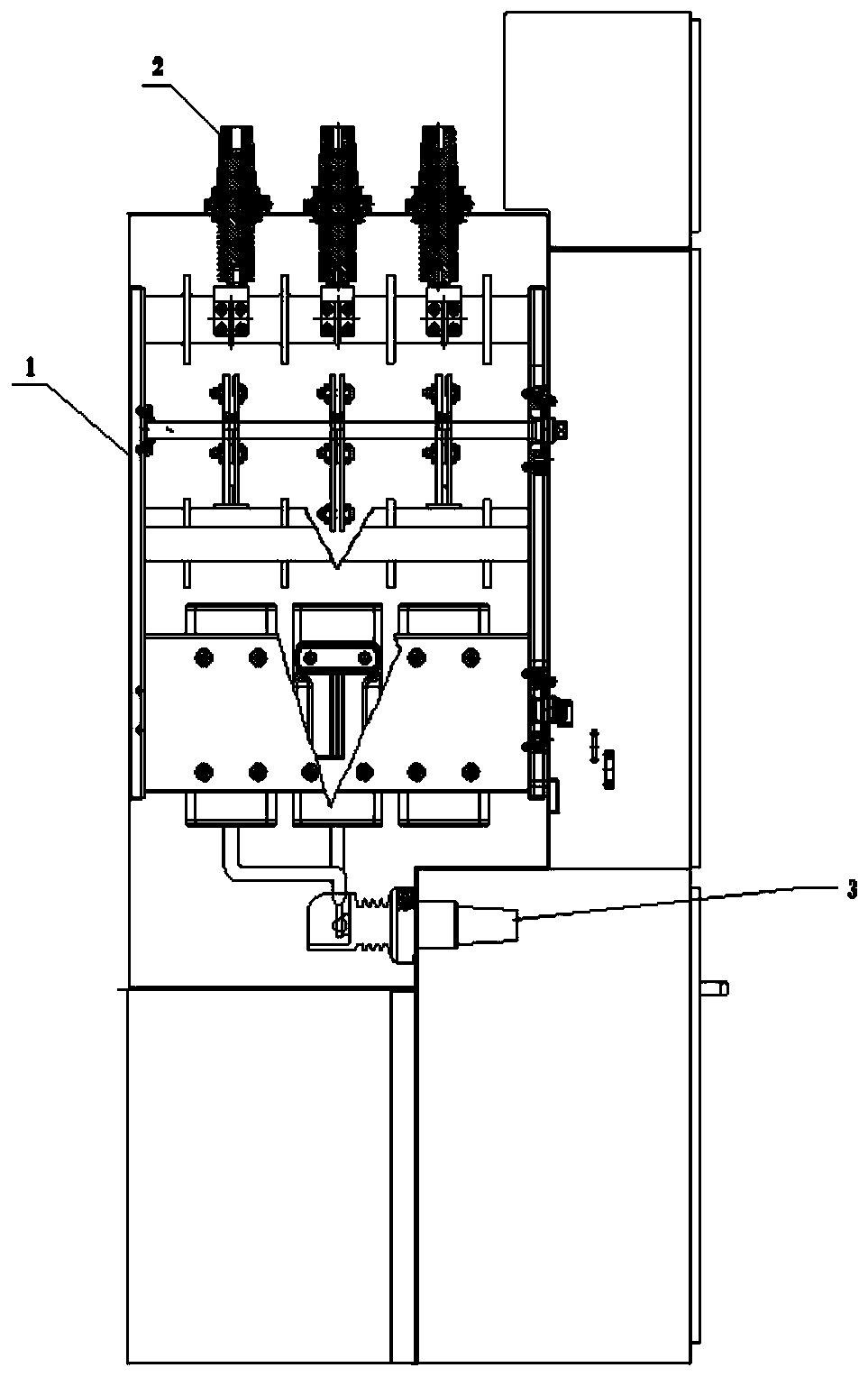

Novel environmental-protection-gas insulated totally-enclosed all-insulation ring network switch equipment

A gas-insulated, ring-network switch technology, applied in the setting of switchgear, switchgear, electrical components, etc., can solve the problems of fully enclosed gas box temperature rise, weak adsorption capacity, and small molecular weight of nitrogen, etc., to achieve Eliminate false fractures, improve heat capacity, and reduce oxygen corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

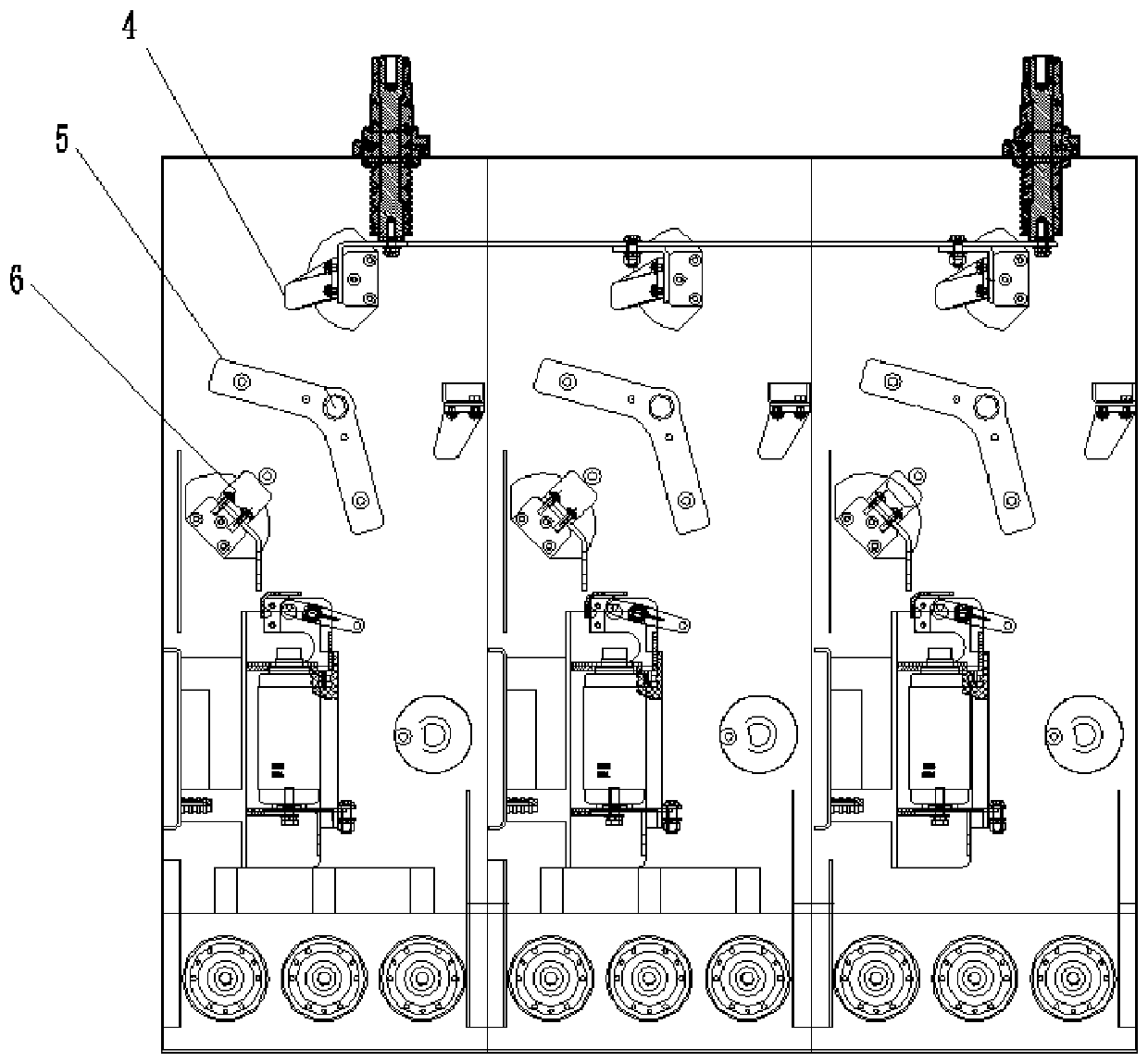

[0039] Embodiment 1: The isolated upper contact and the grounding static contact are arranged symmetrically along the isolated lower contact, and the isolated upper contact and the grounding static contact are arranged in a figure-eight shape as a whole; the double-headed isolated movable knife plate One of the blades swings between the isolated upper contact and the isolated lower contact, and the other blade of the double-headed isolated movable blade swings between the isolated lower contact and the isolated lower contact. between the grounding static contacts. When the double-head isolating moving knife board rotates 60° clockwise, one of the two-head isolating moving knife plates is in contact with the lower contact of the isolation, and the other is in contact with the upper contact of the isolation to realize the closing position. In the current position, rotate 60°counterclockwise, one of the double-headed isolation moving blades will contact with the isolation lower c...

Embodiment 2

[0040] Embodiment 2: The isolated lower contact and the grounding static contact are arranged symmetrically along the isolated upper contact, the isolated upper contact is arranged vertically downward, and the isolated lower contact and the grounding static contact The head is arranged in a V-shape as a whole; one of the blades of the double-headed isolated movable blades swings and switches between the isolated upper contact and the isolated lower contact, and the other of the double-isolated movable blades A blade swings to switch between the isolated upper contact and the grounding static contact.

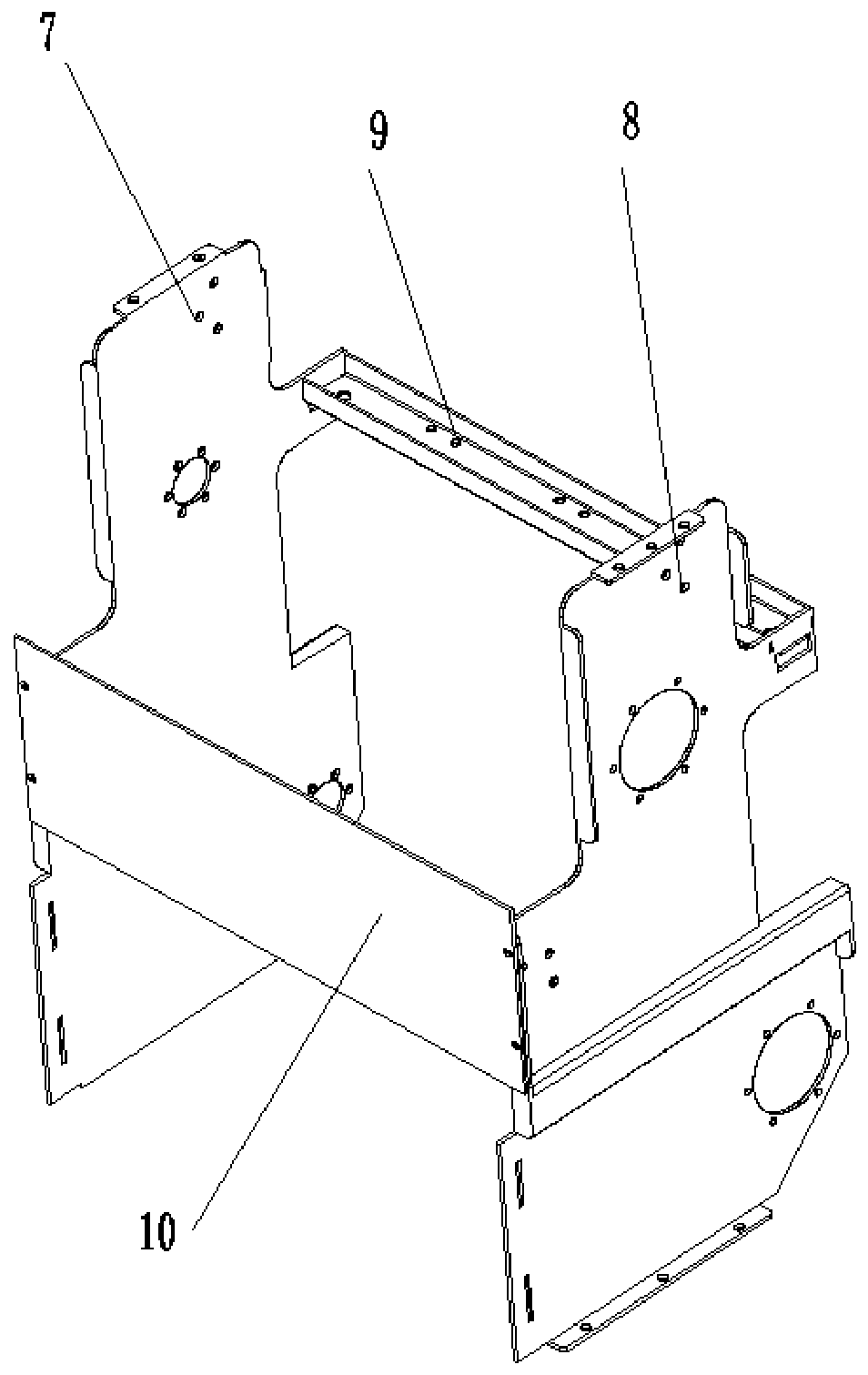

[0041] The isolated moving tool holder 3-1 is in clearance fit with the insulating upper main shaft 1-1 through a floating mechanism, the floating mechanism includes an insulating positioning sleeve and an elastic steel pin, on the insulating upper main shaft 1-1, along the insulating The axially upward sliding sleeve of the upper main shaft 1-1 is fitted with an insulating posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com