A rapid start-up method for a bioelectrochemical process for deoxygenation of oilfield wastewater

A technology of bioelectrochemistry and oilfield wastewater, applied in chemical instruments and methods, combined electrochemical and biological treatment, mining wastewater treatment, etc., can solve the problem of low power generation capacity of MFC operation, reduce oxygen corrosion, and improve biodiversity performance, water quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

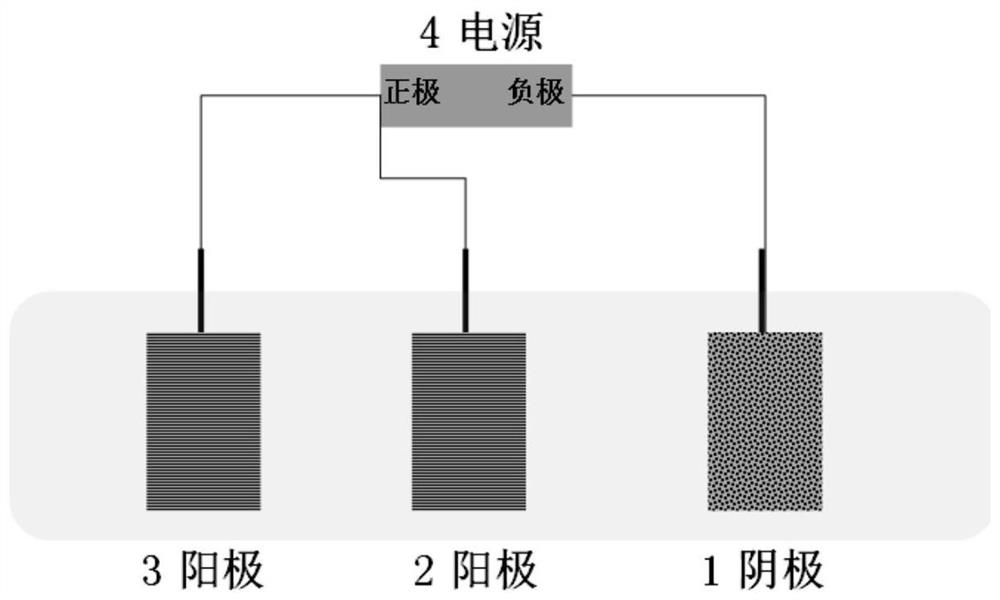

Method used

Image

Examples

Embodiment 1

[0030] (1) Reactor effective volume 1.8L, high diameter ratio of 15: 1.

[0031] (2) The water formulation is as follows:

[0032] Acetate concentration of 1.0 g / l; 1 ml / L of vitamin liquid and 1 ml / L of trace element solution, 50 mM phosphate buffer solution (pH 7.0): Phosphate buffered solution main component concentration: 11.55 g / L twelve hydrogen phosphate 2 Sodium, 2.77 g / L dihydrate, 0.31 g / L ammonium chloride, 0.13 g / L, potassium chloride; vitamin liquid main component concentration: vitamin H, 0.2 g / l, folic acid, 0.2g / L, Vitamin B6, 1g / L, Riboprin, 0.5g / L, Vitamin B1, 0.5g / L, Niacin, 0.5g / L, Pantotheno Acid, 0.5g / L, B-12, 0.01g / L, P- Aminobenzoic acid, 0.5 g / l, sulfic acid, 0.5 g / L.

[0033] The main component concentration of trace elements is: MgSO 4 3g / L, MNSO 4 · H 2 O 0.5g / L, NaCl 1g / L, FESO 4 · 7h 2 O 0.1g / l, CACL 2 · 2h 2 O 0.1g / L, CoCl 2 · 6h 2 O 0.1g / l, ZnCl 2

[0034] 0.13g / L, CUSO 4 · 5h 2 O 0.01g / L, Alk (SO 4...

Embodiment 2

[0044] (1) Reactor effective volume 1.8L, high diameter ratio of 15: 1.

[0045] (2) The water formulation is as follows:

[0046] Acetate concentration of 1.2 g / L; 1 ml / L of vitamin liquid and 1.5 ml / L of trace element solution (pH 7.0): Phosphate buffered solution main component concentration: 12.3 g / L twelve hydrogen phosphate Disodium, 2.95 g / l Dihydrate sodium dihydrogen, 0.5 g / L ammonium chloride, potassium chloride, potassium chloride; vitamin liquid main ingredient concentration vitamin H, 0.3 g / l, folic acid, 0.3g / L, Vitamin B6, 1.2g / L, riboflavin, 0.6 g / l, vitamin B1, 0.6g / L, niacin, 0.6 g / l, pantothenic acid, 0.6 g / l, b-12, 0.03 g / l, p - Aminobenzoic acid, 0.6 g / L, sulfuric acid, 0.6 g / L.

[0047] The main component concentration of trace element fluid includes MGSO 4 3.5g / L, MNSO 4 · H 2 O 0.6g / l, NaCl

[0048] 1.2g / L, FESO 4 · 7h 2 O 0.2g / L, CACL 2 · 2h 2 O 0.2g / L, CoCl 2 · 6h 2 O 0.2g / L, ZnCl 2 0.25g / L, CUSO 4 · 5h 2 O 0....

Embodiment 3

[0057] The startup effect test of Example 2:

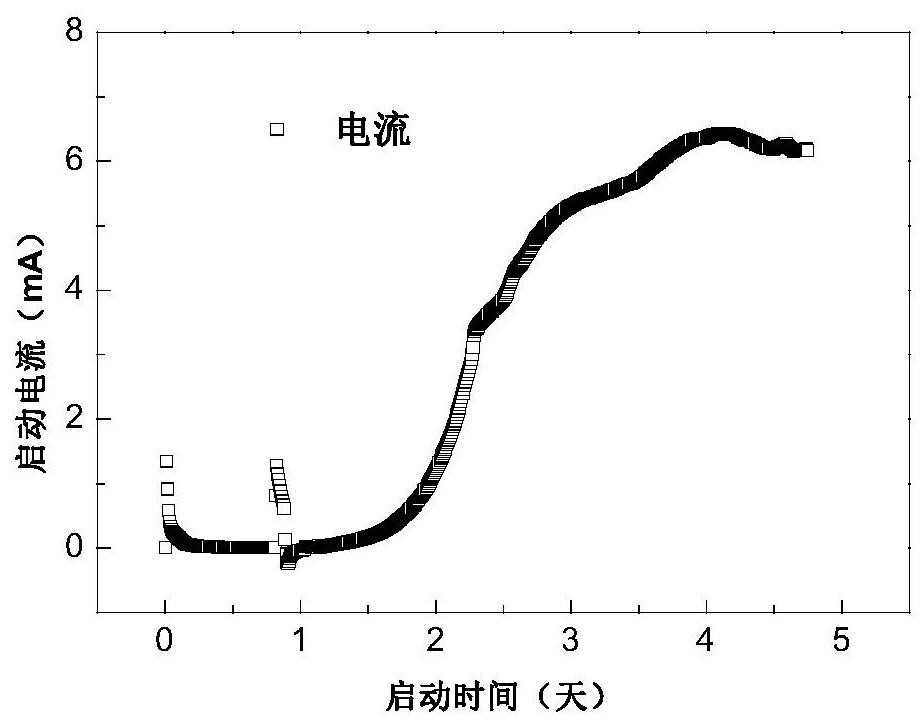

[0058] (1) such as figure 2 As shown, the current is fluctuating when the current starts in the water, then steadily, in the second day inlet water dissolved from 2 mg / L to 4 mg / L, the current fluctuates, then smooth, and stable, improved, from The next day, it began to rapidly, on day 6, the maximum, 6.4mA, and then started steady, from day 5, the current was basically maintained at 6mA.

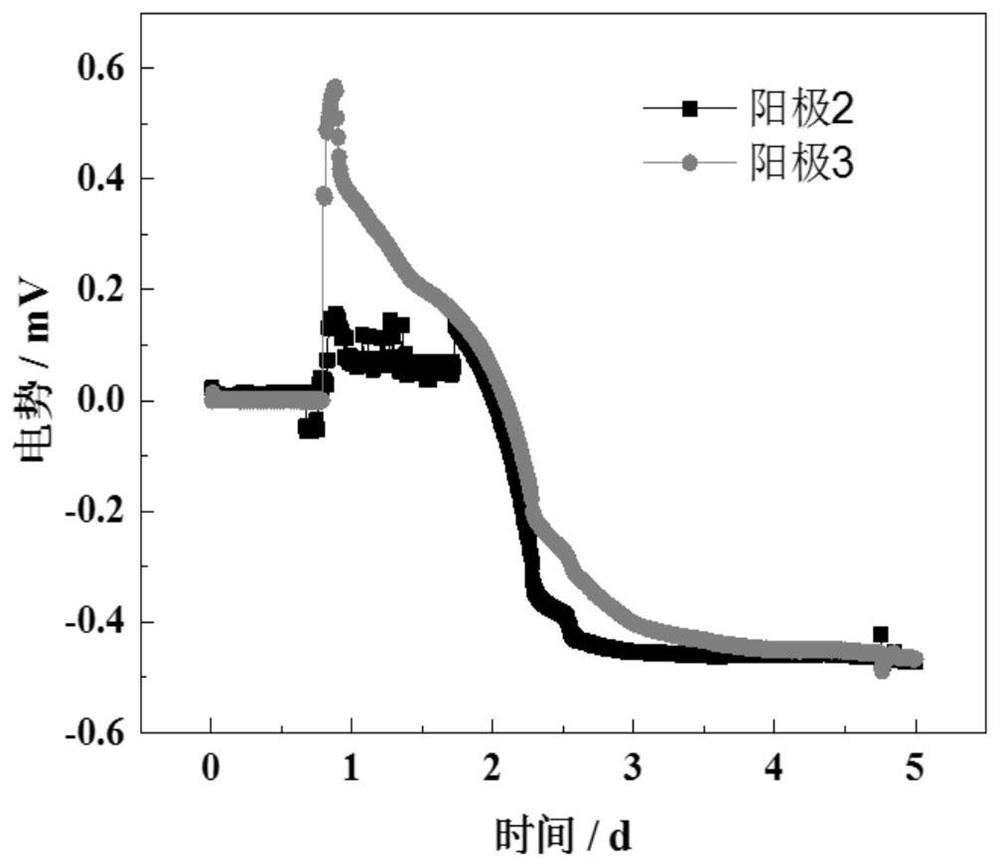

[0059] (2) image 3 It can be seen that the two anode potentials have decreased rapidly during the startup period, and the starting period is from 0 mV (VS AG / AGCL), respectively.

[0060] (3) according to Figure 4 It can be seen that after the start is stable, the water concentration of water is 1000 mg / L, the water is about 600 mg / L, and the removal rate is 40%. After testing, the anode Kurlen efficiency was 4% after stable operation.

[0061] (4) See Figure 5-6 In the start of the domestication stage, the anode potential continued to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com