Energy-saving device for producing oxygen-free pure water by utilizing waste heat and method for preparing oxygen-free pure water

An energy-saving device and energy-saving equipment technology, applied in water/sewage treatment, chemical instruments and methods, degassed water/sewage treatment, etc. The effect of low cost and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

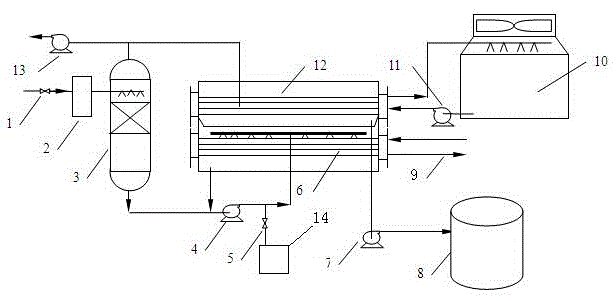

[0028] see figure 1 , an energy-saving device utilizing waste heat to produce oxygen-free pure water, the energy-saving device includes a preheater 2, a vacuum deaerator 3, a circulating water cooling device, and a condenser 12, and one end of the vacuum deaerator 3 is connected to the preheater Heater 2, the other end is connected with circulating water cooling equipment 4, and described circulating water cooling equipment is arranged as circulating pump 4, and the other end of described circulating water cooling equipment is connected with condenser 12, and this energy-saving device also includes soft water feed valve 1, The soft water feed valve 1 is arranged at the front end connected to the preheater 2 . The entire technical scheme is ingeniously designed, fully utilizes the waste heat of existing equipment to prepare anaerobic pure water, reduces energy waste, and reduces the production cost of the enterprise.

Embodiment 2

[0030] see figure 1 , as an improvement of the present invention, the energy-saving equipment also includes an evaporator 6, and a condenser 12 is arranged above the evaporator 6; the energy-saving equipment also includes a cooling tower 10, and the condenser 12 and the cooling tower 10 is provided with cooling circulating water pump 11. The equipment in this technical solution includes a condenser 12 and a cooling tower 10 to realize the secondary vacuum condensation process, remove the precipitated oxygen and non-condensable gas, and further reduce the oxygen content in the pure water. All the other structures and advantages are identical to Embodiment 1.

Embodiment 3

[0032] see figure 1 , as an improvement of the present invention, the energy-saving equipment further includes a deoxygenated pure water tank 8 , and a pure water pump 7 is arranged between the deoxygenated pure water tank 8 and the condenser 12 . The technical scheme is equipped with a vacuum deaerator and a deaeration pure water tank, which realizes two vacuum deaeration. The deaeration greatly reduces the dissolved oxygen and other non-condensable gases in the water, and reduces the pumping load of the vacuum water making unit. Oxygen corrosion is also reduced. All the other structures and advantages are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com