Insulation structure of leading-out electrode/leading-out support rod of heater of high-temperature furnace

A technology of extracting electrodes and insulating structures, applied in lighting and heating equipment, ohmic resistance heating parts, furnaces, etc., to achieve the effect of saving replacement costs, easy implementation, and good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment technical scheme of the present invention is described in detail as follows:

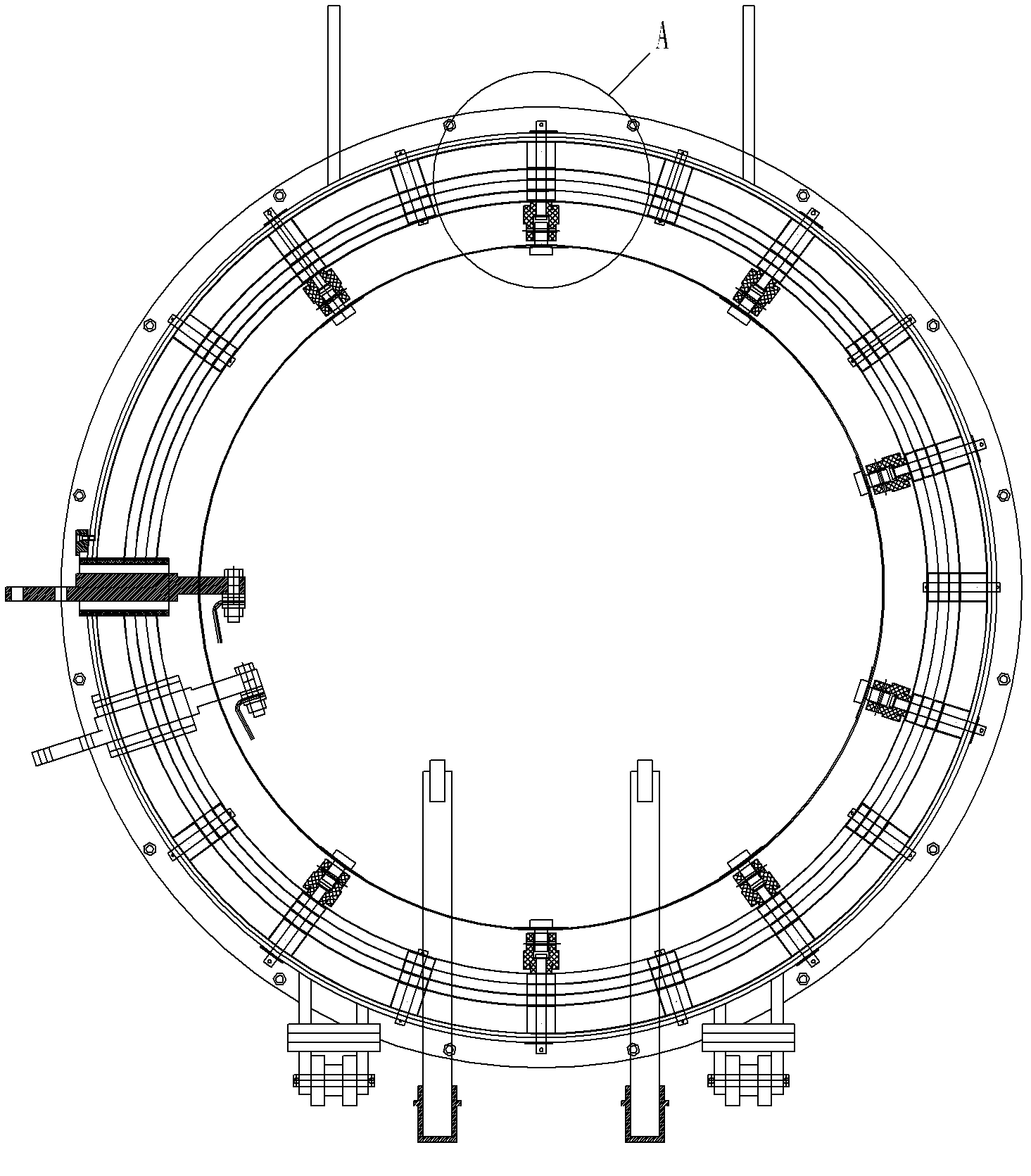

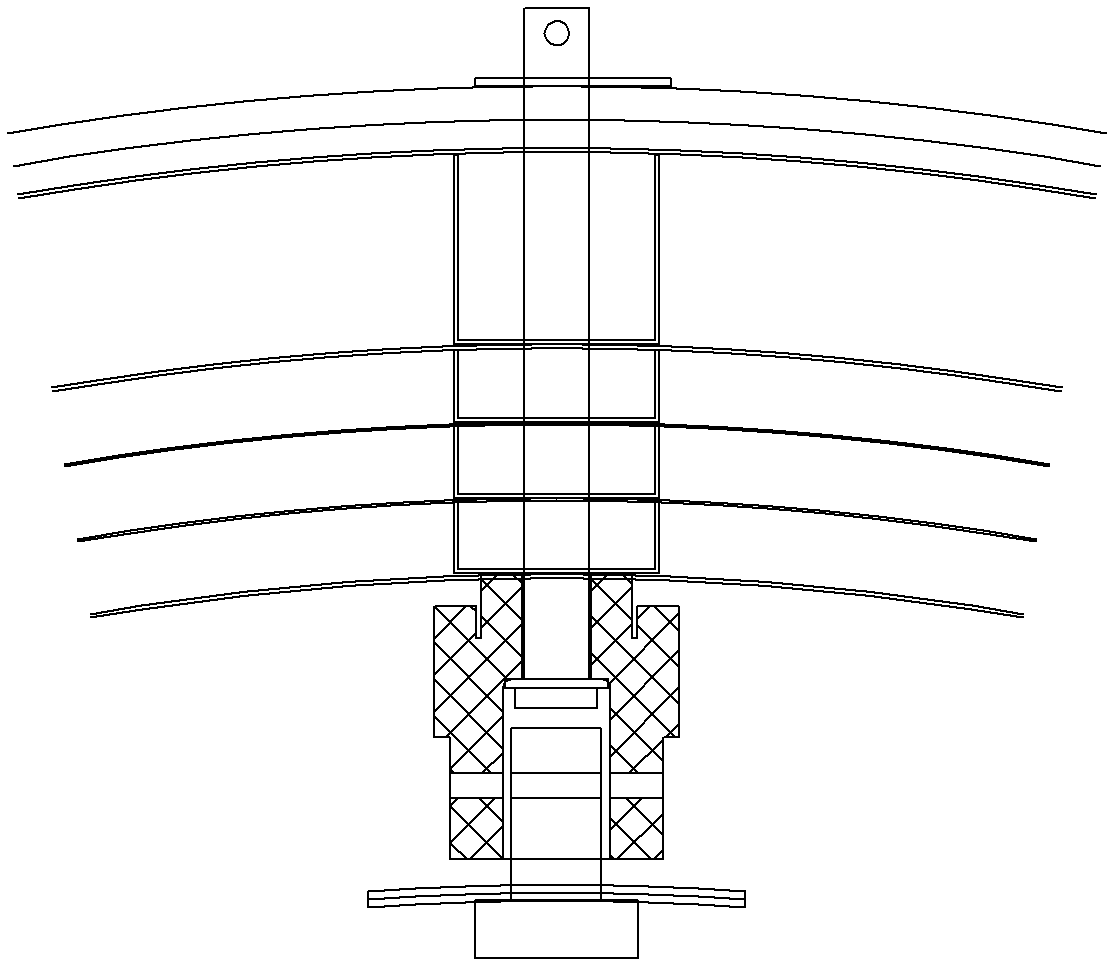

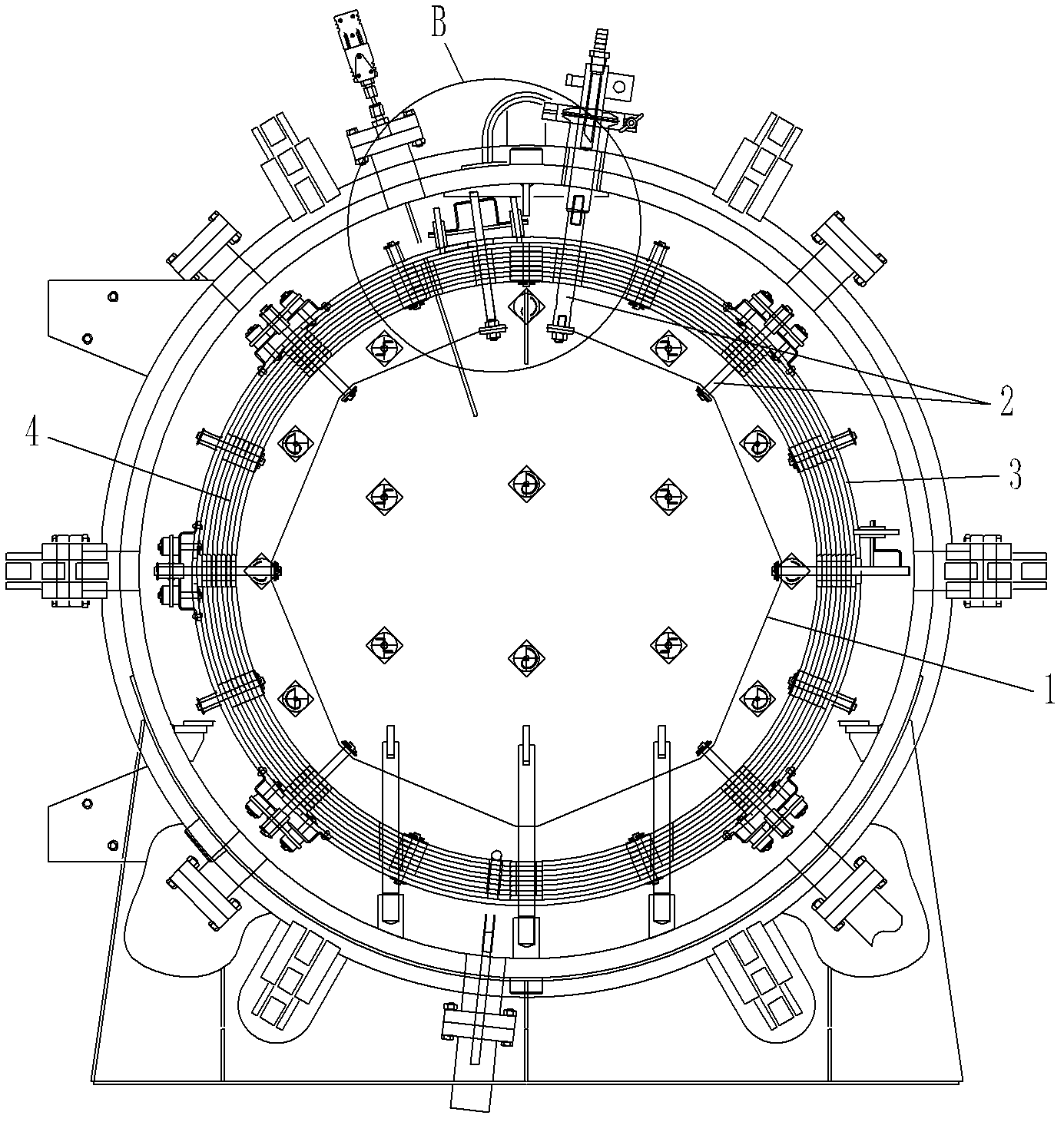

[0017] as attached image 3 to attach Figure 5 As shown, the present invention provides an insulation structure for leading out electrodes / leading support rods of a high-temperature furnace heater 1. A plurality of leading electrodes or leading supporting rods 2 are arranged on the heater 1 in the high-temperature furnace. These leading electrodes or leading supporting rods The rod 2 is fixed on the furnace body 3 through the through hole on the insulation screen 4 between the furnace body 3 and the heater 1 and the through hole on the furnace body 3. These lead-out electrodes or lead-out support rods 2 include electrodes with large diameters. Lead-out electrodes or lead-out support rods and small-diameter positioning lead-out electrodes or lead-out support rods, each lead-out electrode or lead-out support rod 2 and the furnace body 3 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com