Skeleton fiber bundle optical cable with semicircular skeleton grooves

A technology of optical fiber bundle and semicircle, which is applied in the field of skeleton optical fiber bundle optical cable, which can solve the problems of large fiber attenuation of optical fiber ribbon, large diameter of optical fiber ribbon cable, and low yield rate, etc., and achieve the effect of solving the effect of large diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

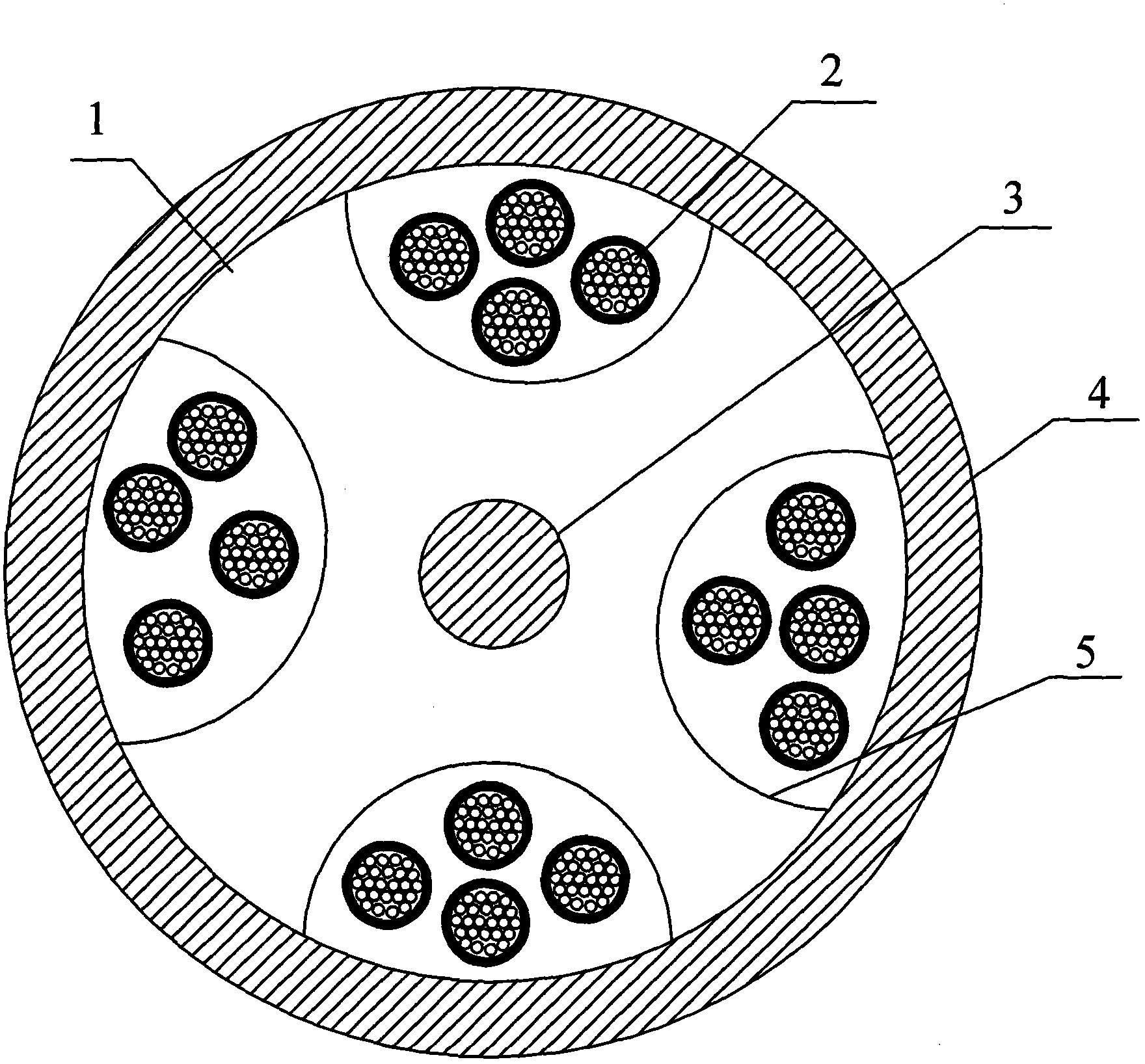

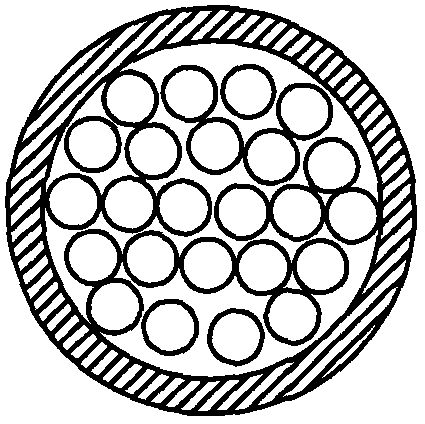

[0025] Embodiment 1: 4 semicircular skeleton grooves, 24 optical fibers built in each optical fiber bundle.

[0026] see figure 1 As shown, the skeleton-type optical fiber bundle cable with a semicircular skeleton groove provided by Embodiment 1 of the present invention includes a skeleton 1 that is extruded from a polymer material and has a cylindrical hollow structure. Shaped central reinforcement 3, the outer wall is extruded with a layer of outer sheath 4, and the inner wall is evenly distributed along the circumferential direction with 4 skeleton grooves 5 with a semicircular cross section, and the 4 semicircular skeleton grooves 5 are along the axis of the skeleton 1. Distributed in a spiral direction, each semicircular skeleton groove 5 is distributed with 4 optical fiber bundles 2 with a circular cross section, and each optical fiber bundle 2 has 24 built-in optical fibers, see figure 2 shown.

Embodiment 2

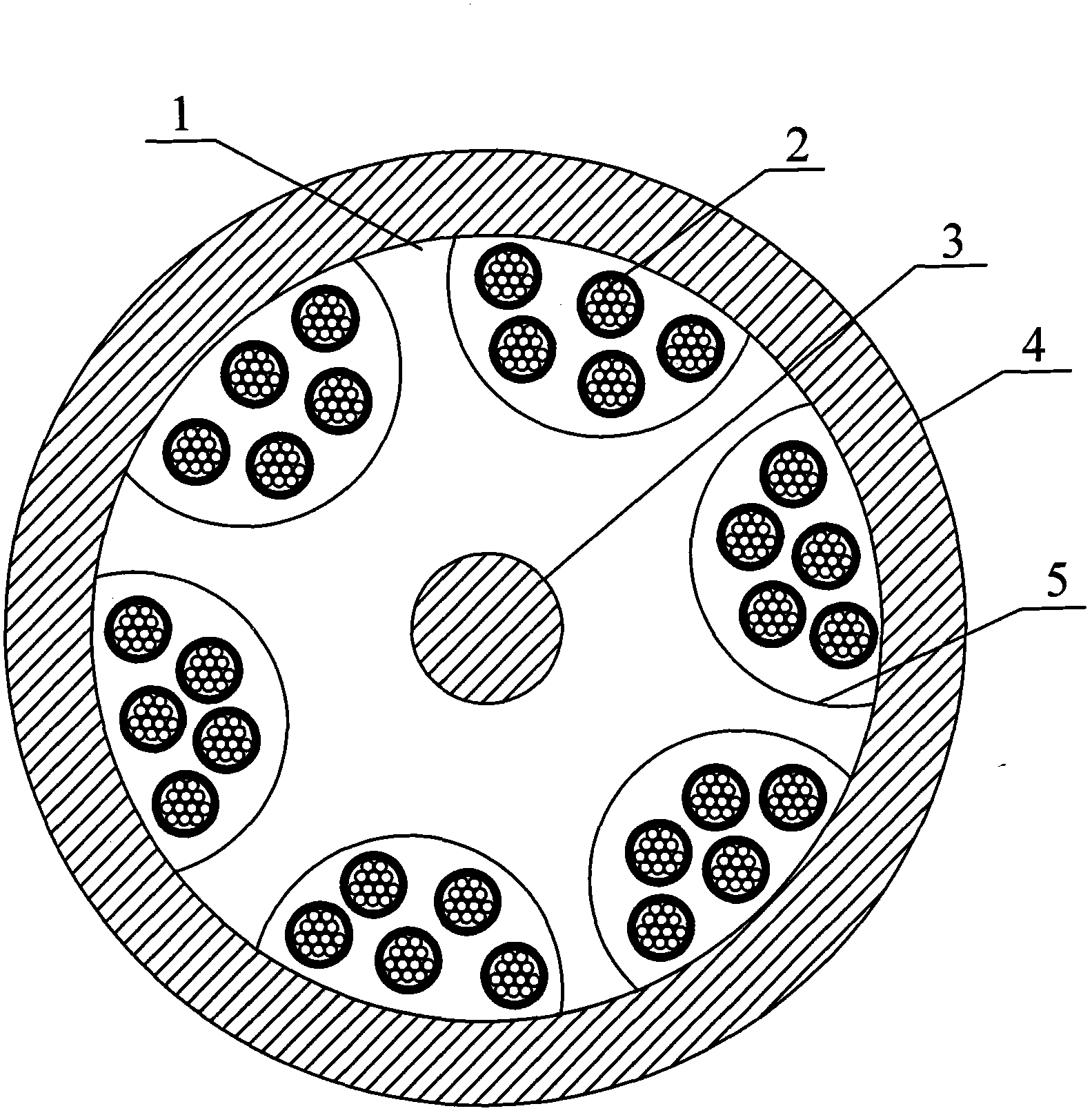

[0027] Embodiment 2: 6 semicircular skeleton grooves, each fiber bundle contains 12 optical fibers.

[0028] see image 3 As shown, the skeleton-type optical fiber bundle cable with a semicircular skeleton groove provided by Embodiment 1 of the present invention includes a skeleton 1 that is extruded from a polymer material and has a cylindrical hollow structure. The outer wall is extruded with a layer of outer sheath 4, and the inner wall is evenly distributed along the circumferential direction with 6 skeleton grooves 5 with a semicircular cross section, and the 6 semicircular skeleton grooves 5 are along the axis of the skeleton 1. Distributed in a helical direction, five optical fiber bundles 2 with a circular cross section are distributed in each semicircular skeleton groove 5, and each optical fiber bundle 2 has 12 built-in optical fibers, see Figure 4 shown.

Embodiment 3

[0029] Embodiment 3: 8 semicircular skeleton grooves, each fiber bundle contains 12 optical fibers.

[0030] see Figure 5 As shown, the skeleton-type optical fiber bundle cable with a semicircular skeleton groove provided by Embodiment 1 of the present invention includes a skeleton 1 that is extruded from a polymer material and has a cylindrical hollow structure. Shaped central reinforcement 3, the outer wall is extruded with a layer of outer sheath 4, and the inner wall is evenly distributed along the circumferential direction with 8 skeleton grooves 5 with a semicircular cross section, and the 8 semicircular skeleton grooves 5 are along the axis of the skeleton 1. Distributed in a spiral direction, each semicircular skeleton groove 5 is distributed with 4 optical fiber bundles 2 with a circular cross section, and each optical fiber bundle 2 has 12 built-in optical fibers, see Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com