Production process of integrated surface-mounted light emitting device

A light-emitting device and production process technology, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of inability to produce high-resolution display screens, welding yield of bracket pins, and technical difficulties in the production process, etc. problem, to achieve the effect of solving the difficulty of controlling the one-time pass rate, small size and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The production process of the light emitting device proposed by the present invention includes the steps of encapsulation, cutting, binning, testing and the like.

[0026] Each step is explained in detail below:

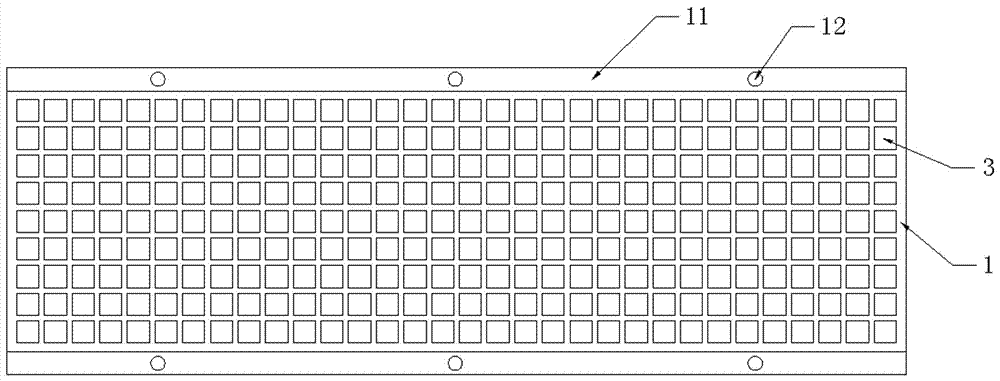

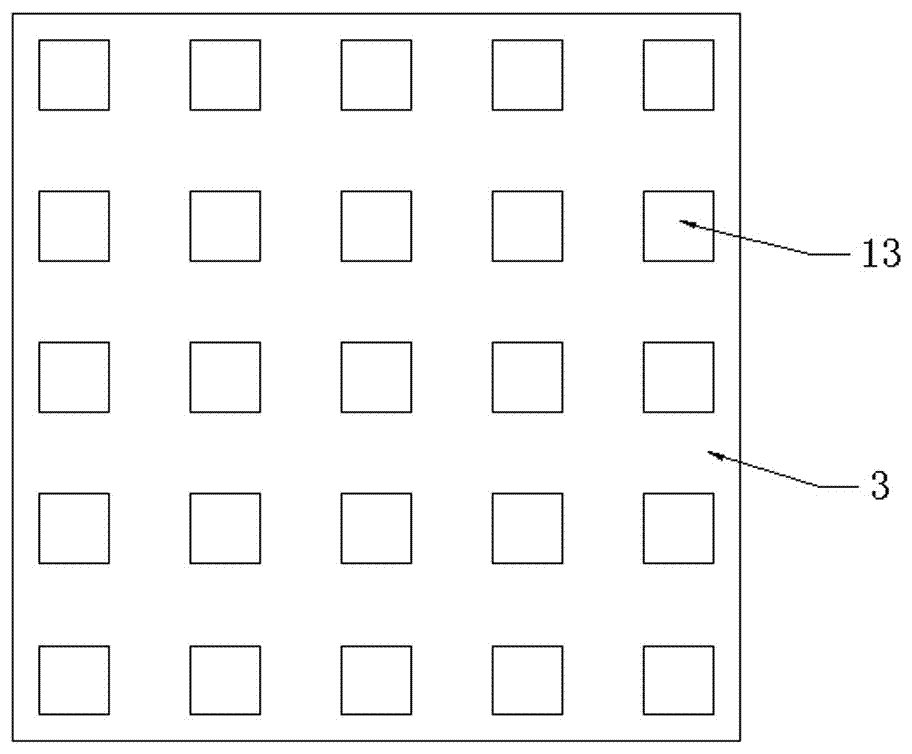

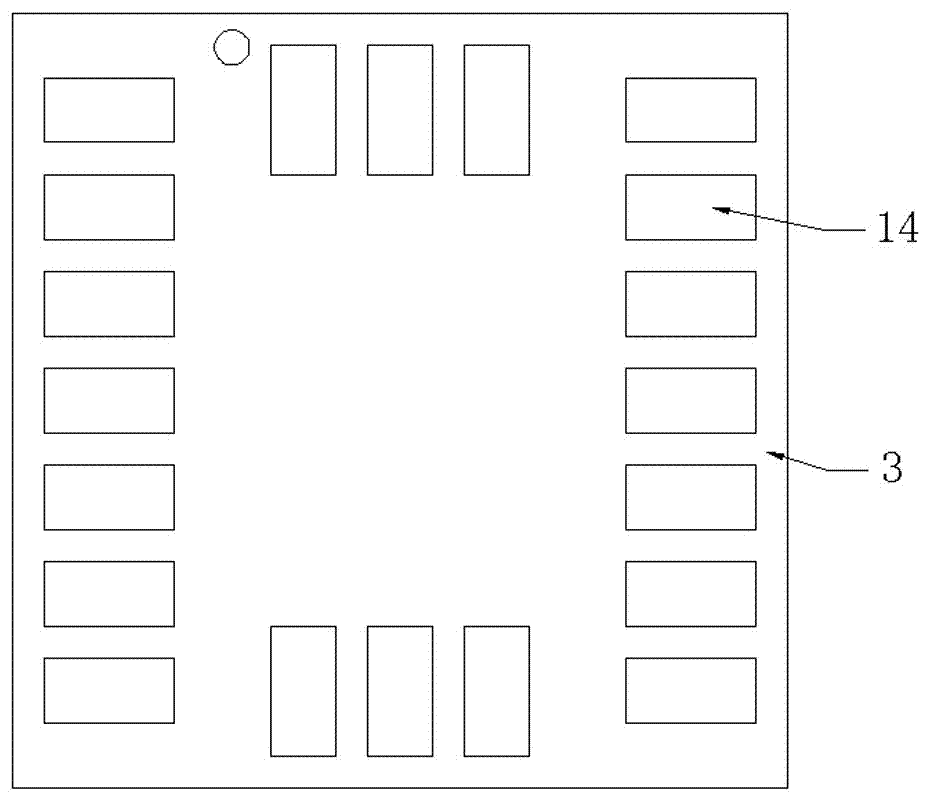

[0027] Step 1, such as figure 1 As shown, the substrate 1 is pre-imposed according to the needs. The upper and lower sides of the substrate 1 are provided with process edges 11, and the process edges 11 are provided with positioning holes 12 to facilitate subsequent processing on the substrate 1. Substrate 1 is a black double-sided circuit board or multi-layer circuit board. The material of substrate 1 is BT, carbon fiber or FR4. hole. Such as figure 2 , 3 As shown, the front of the substrate 1 is provided with several pads 13 for packaging LED chips, and the back of the substrate 1 is provided with several pads 14 for welding control pins.

[0028] Such as Figure 4 As shown, several light-emitting point groups are arranged and packaged on the front su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com