Novel height-adjustable building bracket

A high-level and new technology, applied in the direction of construction, building structure, and construction components on-site preparation, etc., can solve the problems of shortened service life, inconvenient loading and unloading, and affecting work efficiency, so as to improve work efficiency, avoid construction inconvenience, The effect of the convenience of adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. If there are exemplary contents in these embodiments, they should not be construed as limiting the present invention.

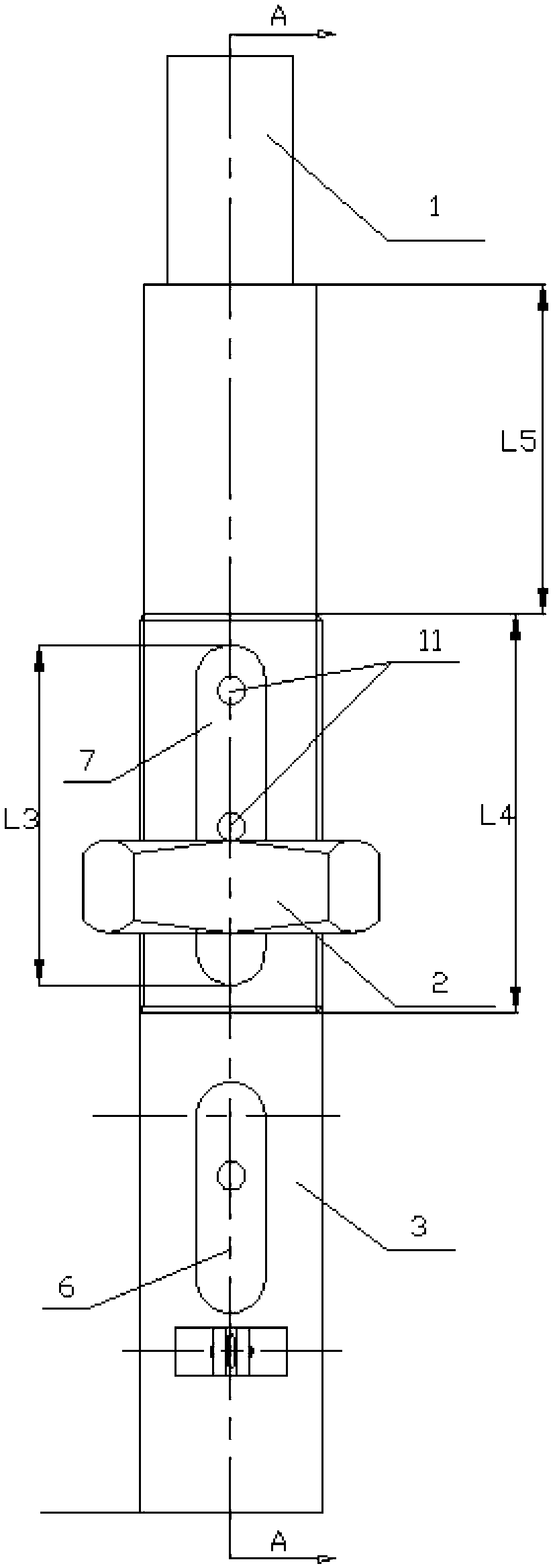

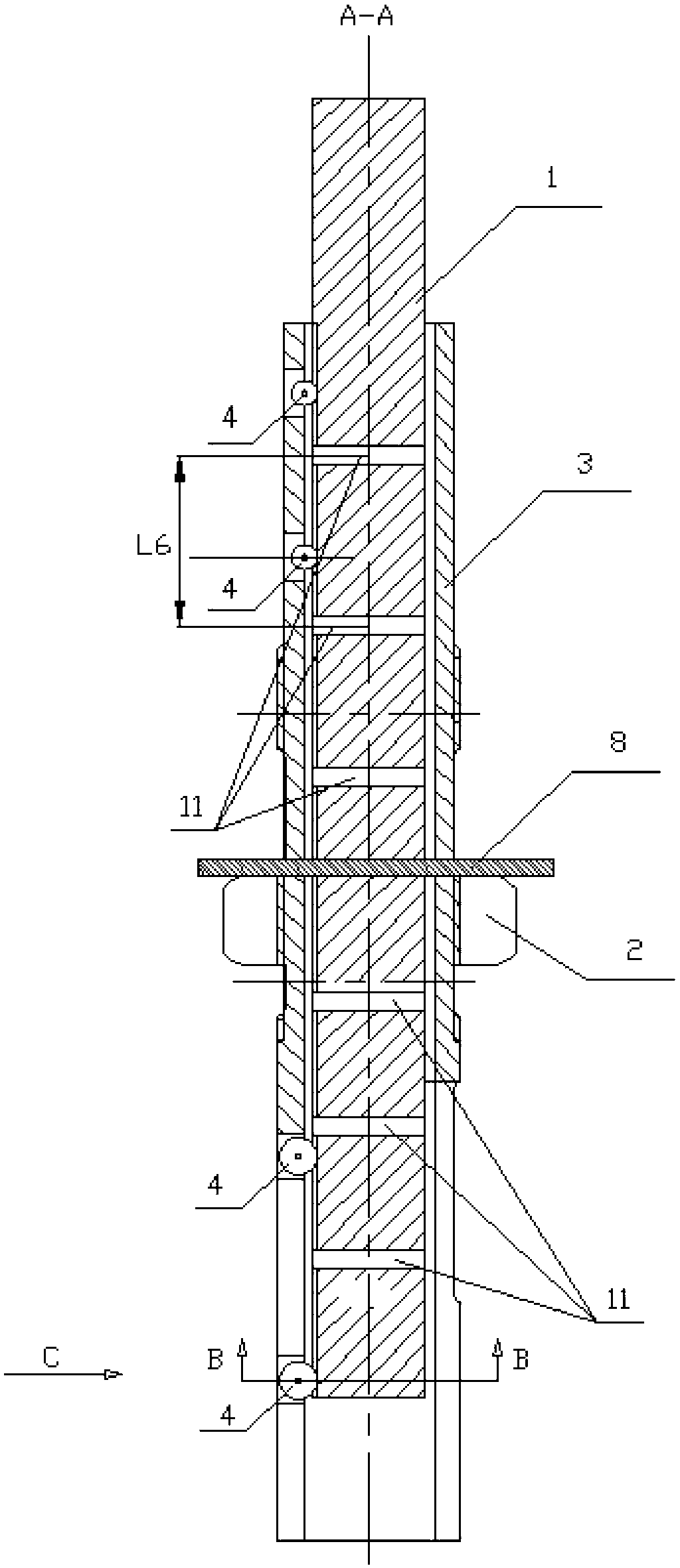

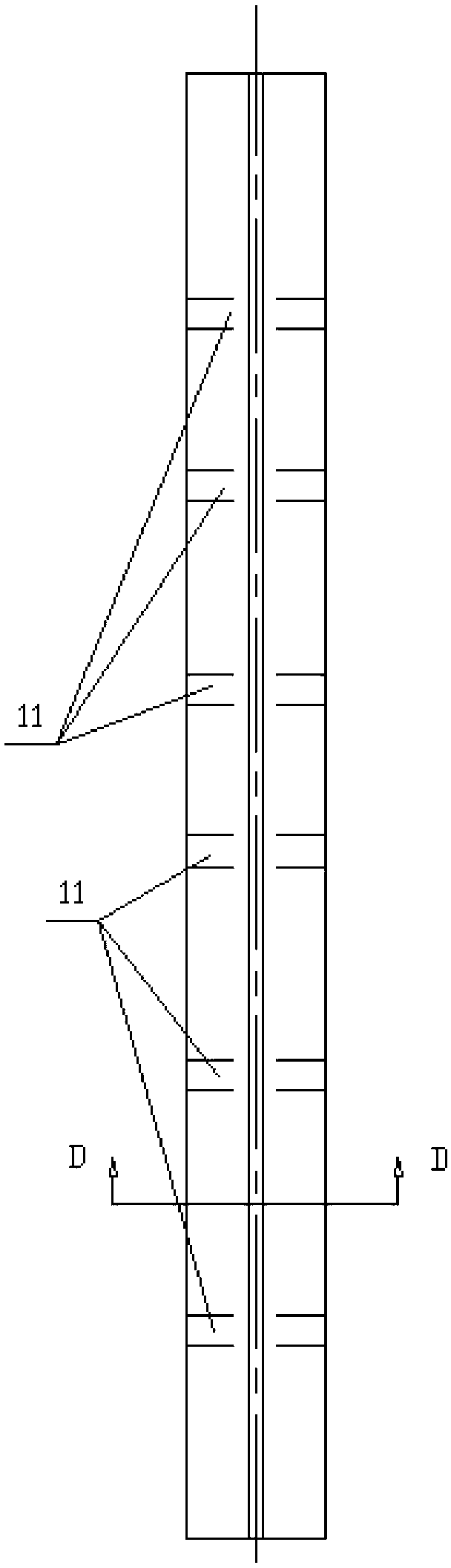

[0028] Such as Figure 1-7 As shown, the outer diameter of the upper end of the sleeve 3 is provided with threads, and the outer diameter of the threaded part of the sleeve 3 is less than or equal to the threaded inner diameter of the adjusting nut 2, so as to facilitate the loading and unloading of the adjusting nut 2. The threaded part of the sleeve 3 is provided with There is a sleeve groove 7, and the lower part of the upper threaded part of the sleeve 3 is provided with a lifting adjustment groove 6 (the lifting adjustment groove can also be set on the upper part of the thread, and in this invention, only the lifting adjustment groove 6 is set on the lower part of the sleeve 3 as an example) , there is a notch for placing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com