A kind of normal temperature curing silicate high temperature resistant adhesive and preparation method thereof

A room temperature curing and adhesive technology, applied in the direction of non-polymer adhesive additives, adhesives, inorganic adhesives, etc., can solve the problems of increasing construction inconvenience and affecting the performance of bonded products, so as to avoid adverse effects and improve High temperature resistance, the effect of avoiding cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The composition raw material of present embodiment high temperature resistant adhesive is as follows:

[0037] Water glass (modulus 2.5) 60%

[0038] Aluminum oxide powder (fineness 500) 20%

[0039] Alumina chopped fibers (length to diameter ratio 20:1) 10%

[0040] Silicon nitride (fineness 500) 6%

[0041] Lanthanum oxide (fineness 500) 2%

[0042] Zirconium diboride (fineness 500) 2%.

[0043] The preparation process of the high temperature resistant adhesive product of the embodiment of the present invention is as follows:

[0044] First grind alumina powder, silicon nitride, lanthanum oxide and zirconium diboride for more than 30 minutes, mix evenly, add alumina chopped fibers into water glass, gradually stir until uniformly dispersed and then use. The application period is about 1.5h.

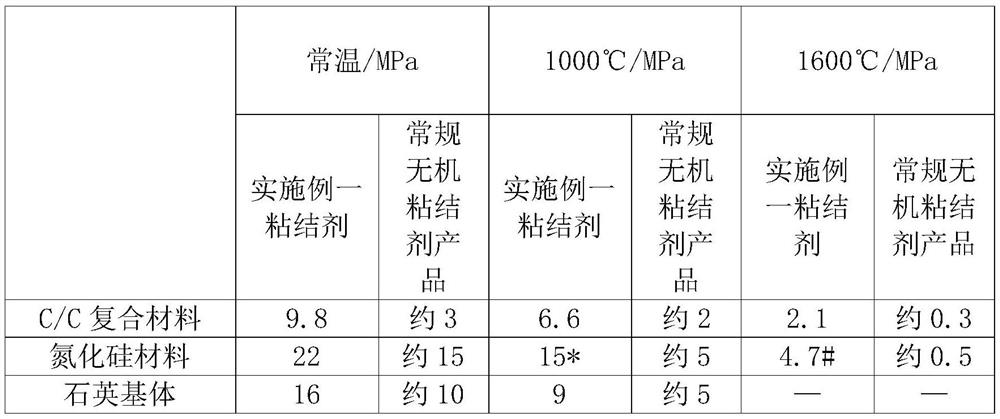

[0045] The fiber-reinforced high-temperature-resistant adhesive of the embodiment of the present invention can be completely cured after standing for 48 hours at normal temp...

Embodiment 2

[0047] The composition raw material of present embodiment high temperature resistant adhesive is as follows:

[0048] Water glass (modulus 3.3) 50%

[0049] Aluminum oxide powder (fineness 200) 30%

[0050] Alumina chopped fibers (length-to-diameter ratio 5:1) 5%

[0051] Silicon nitride (fineness 200) 5%

[0052] Lanthanum oxide (fineness 200) 5%

[0053] Zirconium diboride (fineness 200) 5%.

[0054] The preparation process of the high temperature resistant adhesive product of the embodiment of the present invention is as follows:

[0055] Grind alumina powder, silicon nitride, lanthanum oxide, and zirconium diboride for 40 minutes, mix evenly, add alumina chopped fibers into water glass, stir gradually until uniformly dispersed and ready to use. The application period is about 1.5h.

[0056] The fiber-reinforced high-temperature-resistant adhesive of the embodiment of the present invention can be completely cured after standing for 48 hours at normal temperature and p...

Embodiment 3

[0058] The composition raw material of present embodiment high temperature resistant adhesive is as follows:

[0059] Water glass (modulus 2.0) 40%

[0060] Aluminum oxide powder (fineness 300) 40%

[0061] Alumina Chopped Fiber (Aspect Ratio 10:1) 10%

[0062] Silicon nitride (fineness 200) 5%

[0063] Lanthanum oxide (fineness 100) 2%

[0064] Zirconium diboride (fineness 500) 3%.

[0065] The preparation process of the high temperature resistant adhesive product of the embodiment of the present invention is as follows:

[0066] First grind alumina powder, silicon nitride, lanthanum oxide and zirconium diboride for more than 30 minutes, mix evenly, add alumina chopped fibers into water glass, gradually stir until uniformly dispersed and then use. The application period is about 1.7h.

[0067] The fiber-reinforced high-temperature-resistant adhesive of the embodiment of the present invention can be completely cured after standing for 48 hours at normal temperature and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com