Ultra-thin smooth-type heat-insulation coating

A heat-insulating coating, smooth type technology, applied in the direction of reflection/signal coating, anti-fouling/underwater coating, coating, etc., can solve the problems of poor adhesion between the coating film and the material, easy to float around, poor adhesion, etc., to achieve The surface of the coating film is smooth and not rough, excellent stain resistance, and solves the effect of poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

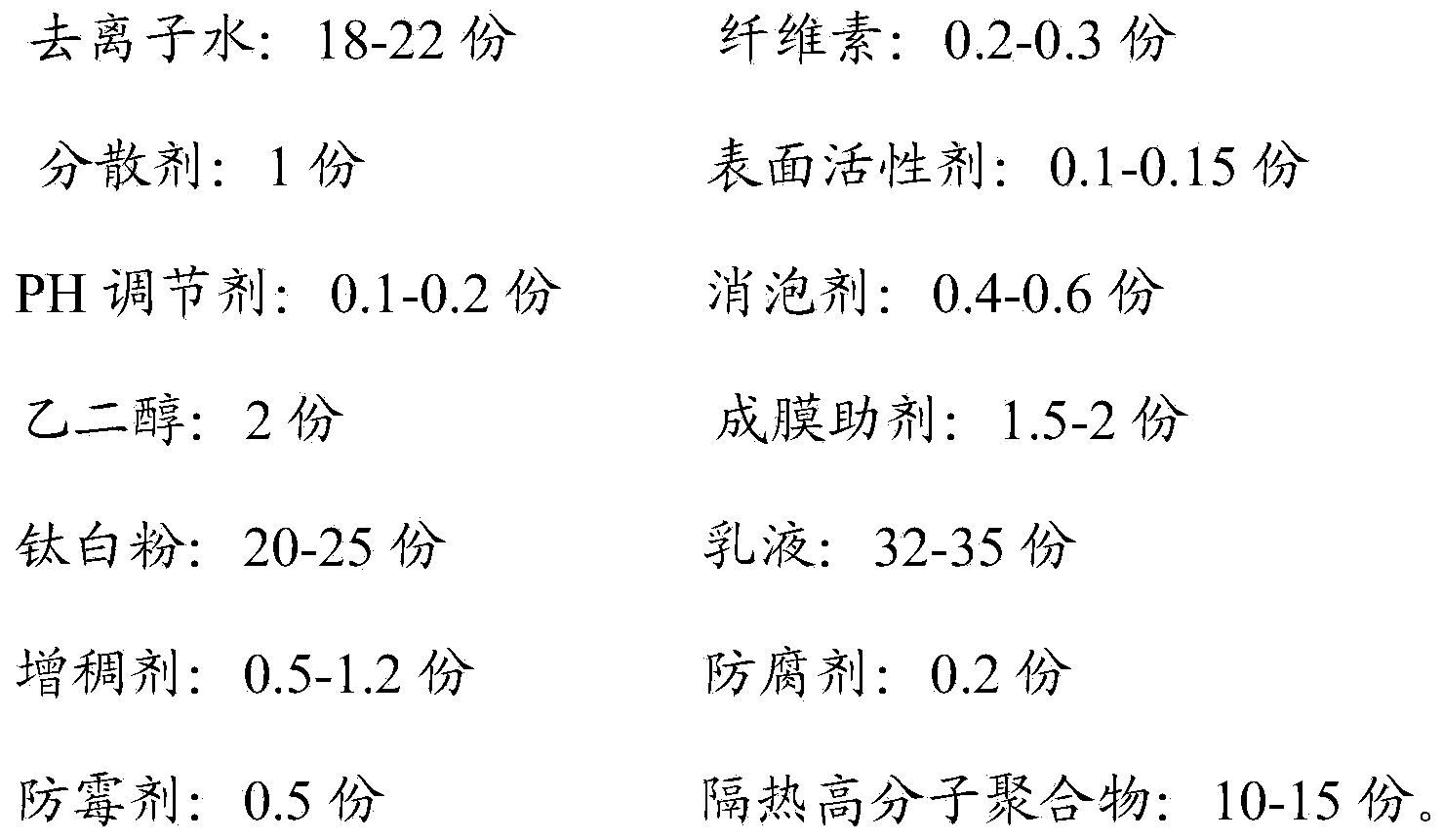

[0017] Embodiment 1: a kind of ultra-thin smooth type heat-insulating coating, it is prepared by the following components by weight:

[0018]

[0019] It can be produced according to the conventional process, such as feeding in order, stirring each material evenly before adding the next material, stirring while feeding, and checking the viscosity after the dispersion is uniform.

Embodiment 2

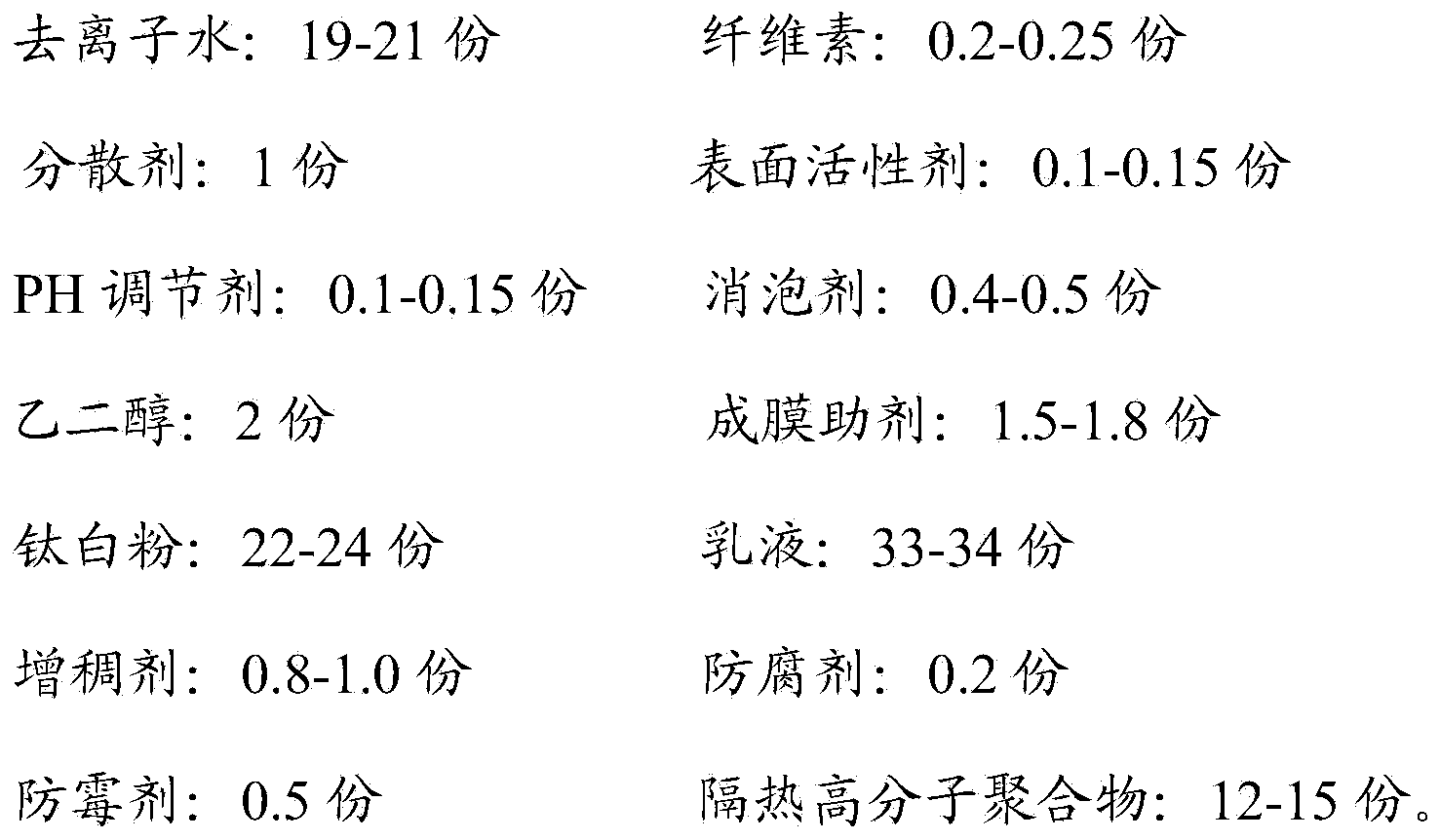

[0020] Embodiment 2: a kind of ultra-thin and smooth heat-insulating paint, is prepared from following components by weight:

[0021]

[0022]

[0023] It can be produced according to the conventional process, such as feeding in order, stirring each material evenly before adding the next material, stirring while feeding, and checking the viscosity after the dispersion is uniform.

Embodiment 3

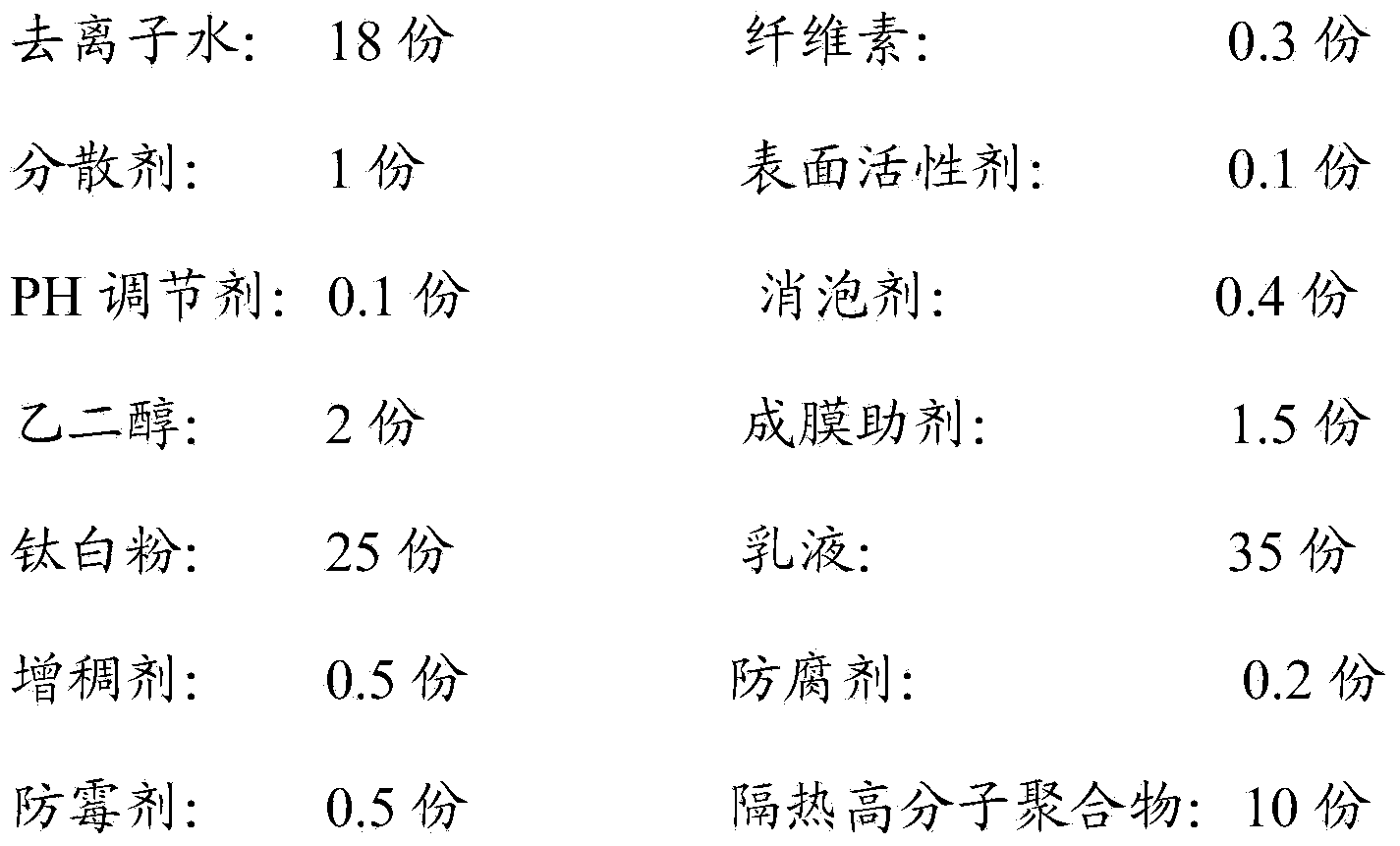

[0024] Embodiment 3: a kind of ultra-thin and smooth heat-insulating paint, is prepared from following components by weight:

[0025]

[0026] It can be produced according to the conventional process, such as feeding in order, stirring each material evenly before adding the next material, stirring while feeding, and checking the viscosity after the dispersion is uniform.

[0027] The coating film that adopts the coating formula described in embodiment 1-3 to be made carries out effect detection test respectively, and detection method adopts national standard GB / T 9755-2001 "Synthetic Resin Emulsion Exterior Wall Coating" and GB / T 25261-2010 " Reflective and heat-insulating coatings for buildings", the test results are as follows: stain resistance ≤ 5, weather resistance ≥ 1200h, adhesion ≤ grade 1; hemispherical emissivity ≥ 0.90, solar reflectance ≥ 0.90. Through the appearance inspection, the board surface is smooth and smooth, without rough feeling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com