Split type hydraulic lifting and climbing frame

A hydraulic lifting and fragmentation technology, which is applied to the accessories of scaffolding, scaffolding supported by house structure, and house structure support, etc., can solve the problems of unsteadiness, complicated process, and many uncertain factors, and achieve high cost and solve process. Complicated, the effect of solving the inconvenience of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

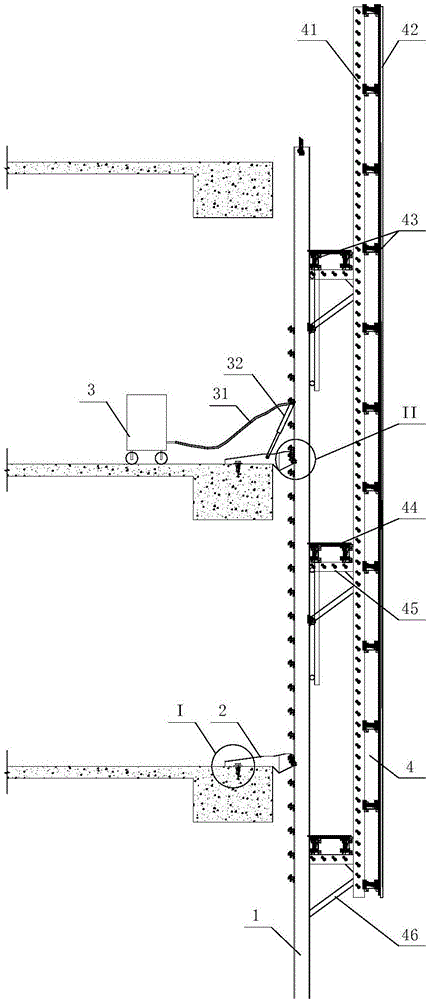

[0036] Such as Figure 1-Figure 6 As shown, a piece-type hydraulic lifting climbing frame according to the present invention includes a guide rail device 1, a connector 2, a mobile hydraulic lifting device, and a climbing frame 4, and the climbing frame 4 is fixedly connected to the guide rail device 1, The guide rail device 1 is connected to the floor of the building through the connector 2, and the mobile hydraulic lifting equipment can lift or lower the guide rail device 1 through its hydraulic jack 32 as required, that is, to realize the lifting of the climbing frame 4 to meet the construction requirements of different heights.

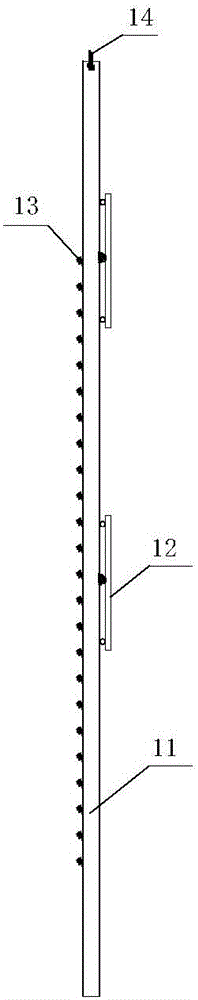

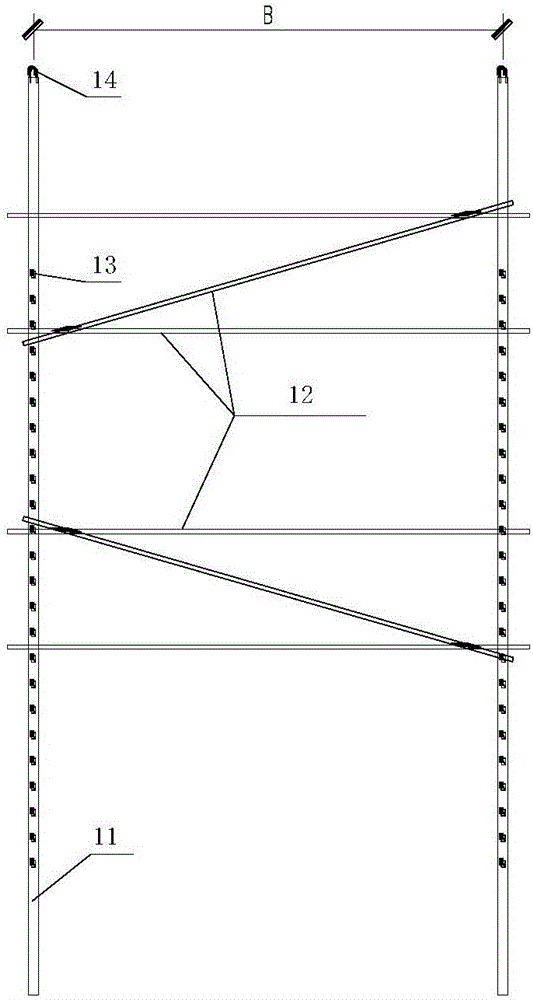

[0037] The guide rail device 1 is composed of a guide rail 11, a reinforcing part 12, a "teeth" part 13, and a suspension ring 14, wherein the guide rail 11 is two parts welded and fixed by the reinforcing part 12 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com